Posters COSI 2005

- G. van Benthem, Polymer Technology Group Eindhoven BV, The Netherlands, We translate science into usable technology!

- F. Busato, IRFAB Chemical Consultants, Belgium, Trends in environment-friendly coatings in Europe 2007 – 2012: How prepared is the European paint industry to meet the 2007 SED deadline? A ’ VOC’ – Voice-of-the-Customer’ Analysis

- T. Dikic, Eindhoven University of Technology, The Netherlands, Self-replenishing-low adherence coatings

- Z. Knesl, Academy of Sciences of the Czech Republic, Czech Republic, Resistance of coated structures to failure

- P. Malanowski, Eindhoven University of Technology, The Netherlands, Weathering and durability of industrial coatings

- J. McDaniel, Reactive Surfaces Ltd., USA, Enzyme-based reactive coatings for chemical warfare and pesticide remediation

- C. Perez Perez, University of Vigo, Spain, The influence of galvanize surface state on the duplex systems behavior

- A.Petrenko, Akzo Nobel, Russia, Optical and mechanical properties of the water-borne decorative coating influenced by the partial pigment substitution

- F. Scaltro, Eindhoven University of Technology, The Netherlands, Durability of Metal Oxide/ Coating Interfaces

- K. Scott, Atlas Materials Testing Technology LLC., USA, Laboratory weathering instruments incorporate revolutionary innovations to meet the testing demands of today's complex coatings

- D. Senatore, Eindhoven University of Technology, The Netherlands, Encapsulation of powder coating cross-linker

- W.J. Soer, Eindhoven University of Technology, The Netherlands, Waterborne anti-corrosion coatings for magnesium surfaces

- D. Wu, Eindhoven University of Technology, The Netherlands, Topologically structured, superhydropobic thermoset coatings

- M. Yuan, Eindhoven University of Technology, The Netherlands, Tunable conductivity levels in nano filler/polymer matriz composites

Drs. Gabriëlle van Benthem

Polymer Technology Group BV Eindhoven, The Netherlands

Title Poster

We translate science into usable technology!

Summary

Polymer Technology Group Eindhoven BV (PTG Eindhoven) is a company which is able to support you in the field of plastics in the broadest sense of the word. Five years ago PTG Eindhoven was founded under the name of Kunststoffenhuis, as part of the Polymer Technology research group at Eindhoven University of Technology (TU/e). In 2005 PTG Eindhoven became an independent company within the TU/e Holding. Through this set up, PTG Eindhoven has access to all the facilities and expertise of the TU/e. In addition to the full- and part-time employees, PTG Eindhoven cooperates with a wide ranging network of specialists/consultants, who are available if needed PTG Eindhoven also acts as an intermediary between the client and the various institutions in the Eindhoven region, such as the Eindhoven University of Technology (TU/e), the Dutch Polymer Institute (DPI), Fontys University of Professional Education and TNO Industry.

Analysis and advise

Imagine your plastic product suddenly fails. You would like to know what polymeric

material is used for your product. You want to select the best material for a new

product. Or you want to pursue a dialogue concerning an idea for a product or

production optimization. For all these questions you can turn to PTG Eindhoven. PTG

Eindhoven will work together with you to analyse the problems which need to be

resolved and the techniques most suited to reach a solution.

Contract Research

During the past decade the plastics industry, and particularly the raw material

producers, have drastically reduced their long term corporate R&D facilities and

have committed the long term fundamental research to universities and institutes,

such as the Dutch Polymer Institute (DPI). Other aspects include producers who have

strongly reduced technical support to the many processing companies, resulting in the

absence of much needed feedback. PTG Eindhoven undertakes to fill this void by

giving support and is therefore able to help solve all questions from SMEs. Besides

this, we also receive increasing numbers of requests for projects, in the form of

contract research with a finite duration, from the plastics producing industry.

Project Management

From the Dutch and European government financial backing is available in the form of

subsidy (Framework 6, CRAFT, etc...). However, to qualify a project for these

subsidies, a great deal of paper work is required. Most companies, in particular

companies from SMEs sector, do not have the time or the man-power to arrange this

administration in the correct format. PTG Eindhoven can do this for you.

Franco Busato

IRFAB Chemical Consultants, Belgium

Title Poster

Trends in environment-friendly coatings in Europe 2007 – 2012: How prepared is the European paint industry to meet the 2007 SED deadline? A ‘VOC’- Voice-of-the-Customer’ Analysis

Summary

As the 2007 deadline for compliance with the European Solvent Emission Directive comes closer, the coatings industry is subject to increasing pressure. Demand is re-directed to Waterborne, Powder, High Solids or Radcure Coatings, fostering development of new innovative products and processes involved in paint application activities. These activities will also be influenced by the new EU Chemical Policy. In this paper the results will be discussed of a large interview panel of paints and coatings users in the different market segments, including automotive OEM, ACE, household appliances, general metal, wood, plastics etc., in Europe and their readiness for the 2007 SED deadline. Specific industry cases will be described where changes in paint technology have occurred with description of the results in terms of performance, cost etc. Additionally, a comparison of environmental regulations in North America and Asia will be examined.

Biography

Franco Busato is a Managing Partner of Irfab Chemical Consultants, based near Brussels, Belgium. Franco Busato has an MSc degree in chemical engineering with a major in polymer chemistry from the Technical University in Delft, The Netherlands. After several years working as a Marketing Manager in the Resin industry and as a Technical Director in the Paint industry, he founded his own consultancy in 1971. His main field experiences are Market and Technology Assessment of Coatings and related Raw Materials, Long-Term Forecasting of Coatings Technologies. Main activities of Irfab concern strategic planning related to new paint technologies and environmental issues, competitive analysis and M&A.

Tamara Dikic

Eindhoven University of Technology, The Netherlands

Title Poster

Self-Replenishing low-adherence coatings!

Authors

T. Dikic, W. Ming, R. van Benthem, G. de With

Summary

Reducing adherence between a coating surface and contaminants can be brought up by

lowering surface energy of the coating, rendering the surface easily cleanable. In our

laboratory we have successfully developed low surface energy cross-linked films via

surface segregation of fluorinated species during film formation. However, the very

thin fluorine-enriched layer might be too vulnerable to sustain various mechanical

forces (scratch, rubbing, etc.), therefore the low adherence character of the films may

be compromised and may disappear eventually.

The objective of the current project is to sustain the water/oil repellency of the

coatings, making the low-adherence character self-replenishing. Our approach to

distribute long fluorinated dangling chains relatively homogeneously in the coating

network. In case of the surface damage that leads to the loss of the fluorinated tails

originally sitting at the surface, due to the mobility of fluorinated tails and the

flexibility of the network, the fluorinated tails from sub-layers will be able to

reorient themselves to minimize the air/film interfacial energy.

Z. Knésl

Institute of Physics of Materials, Academy of Science Czech Republic, Czech Republic

Title Poster

Resistance of coated structures to failure

Authors

Z. Knésl, L. Náhlik

Summary

Protective coatings are frequently used to increase service life of engineering structures. If the coating fails, it may cease to provide its protective function and the intended purpose of the coating is not achieved. Furthermore, the existence of cracks in the coating with their crack tips at the interface represents a singular stress concentrator and can, in some cases, cause the failure of the whole structure. The aim of the contribution is to estimate how the coating crack with its tip at the interface influences the substrate failure. The problem is studied under assumptions of linear elastic fracture mechanics and the corresponding calculations are performed by finite element method. It is shown that in the cases of stiffer coating on more compliant substrate (as a consequence of the elastic mismatch) the through coating crack represents a dangerous stress concentrator and the critical stress for substrate failure decreases. The influence of coating cracks with their crack tip at the interface on substrate failure must be handled very carefully. Estimations of the service life of coated structures (for both static and cyclic loading) neglecting this fact, could lead to non-conservative values and thus cause unexpected failure.

Przemyslaw Malanowski

Eindhoven University of Technology, The Netherlands

Title Poster

Weathering and durability of industrial coatings

Authors

P. Malanowski, R. van Benthem, J. Laven, G. de With

Summary

Introduction

In weathering conditions many factors simultaneously influence the aging of polymeric

materials. UV radiation, heat (high and low temperature), moisture can cause changes in

chemical structure of macromolecules. It leads to loss of physical properties of plastics (cracking, gloss loss, blistering) and reduction of their life-time. In order to improve

polymer photostability there has been a very big effort during the last 30 years to

understand the mechanisms involved in photodegradation and environmental aging. Polymeric

materials are modified and stabilized by numerous compounds but sooner or later are

degraded. The resistance of industrial coating to outdoor exposure is an extremely

important topic. We will be able to improve weathering resistance of polymers by the

discovering and understanding the critical degradation mechanism of this material.

Experimental

Photodegradation of model polyester based on neopentyl glycol and isophthalic acid has

been investigated. Since polymer aging in natural condition is a complex and complicated

process (influence of UV-radiation, temperature, humidity) in this work polyester coating

was exposed to UV radiation in different specific atmospheres (dry air, wet air, dry

nitrogen, wet nitrogen) to distinguish between: photooxidation, photolysis, hydrolysis

etc. Changes in chemical structure of molecules were investigated by ATR–FTIR,

GPC, and MALDIToF MS. The following conclusions were obtained under the experimental

conditions: 1) Photodegradation in air atmosphere causes break-down and generation of

both C=O, OH/OOH groups on polymer surface, as detected by ATR-FTIR spectra, while

degradation in nitrogen was hardly noticeable by ATR-FTIR 2) GPC results show changes of

molecular weight of polyester after irradiation 3) MALDI-ToF MS exhibits appearance of

degradation products. 4) Water doesn’t have affect on degradation process. It has

to be reminded that all of these results were obtained in highly accelerated degradation

tests.

References:

- J. F. Rabek, Polymer Photodegradation – Mechanisms and Experimental Methods, Chapman & Hall, London 1995.

- A. Rivaton. Polymer Degradation and Stability 41 (1993) 297-310.

- P. Gijsman, G. Meijers, G. Vitarelli, Polymer Degradation and Stability 65 (1999) 433-441.

J. McDaniel

Reactive Surfaces Ltd. USA

Title Poster

Enzyme based reactive coatings for chemical warfare and pesticide remediation

Authors

C.S. McDaniel, J. McDaniel, M.E. Wales, J.R. Wild

Summary

Enzymes sequestered in paints and coatings have the potential to provide the fastest decontaminating solid catalysts yet identified. We report here the design and characterization of biocatalytic latex coatings capable of remediating organophosphorus (OP) compounds, which includes many of the commonly used pesticides, as well as the most dangerous chemical warfare agents. The strategy for manufacture of these biocatalytic coatings involves the coupling of the power of biology with off-the-shelf, environmentally friendly coatings. The process involves an adequate entrapment of the biocatalyst in a latex coating, verified by analysis of the kinetic parameters for the enzyme in the coating. The last step in biocatalytic coating synthesis is an estimation of the enzyme ’s operational and storage stability, particularly in the presence of environmental agents. Given our pre-existing base of knowledge of the stability and activity of both native and modified organophosphorus hydrolase (OPH, EC 3.1.8.1), our initial model reaction in the development of catalytic coatings was the OPH-catalyzed hydrolysis of paraoxon, demeton-S and diisopropylfluorophosphate. Success with these enzyme-substrate pairs will be used as the basis for the incorporation of other biocatalysts into films and coatings.

Carmen Pérez

University of Vigo, Spain

Title Poster

The influence of Galvanized Surface State on the Duplex Systems Behaviour

Authors

I. Cabanelas, A. Collazo, M. Izquierdo, X.R. Novoa, C. Peréz

Summary

Painted galvanised steel (duplex system) is a common way of protecting metallic structures. As it is known, the corrosion protection efficiency is strongly dependent on adhesion strength at the paint/zinc interface. Good adherence makes more difficult the aggressive species to reach the metallic substrate and, as a consequence, the corrosion process is avoided or, at least, delayed. Adherence is directly related to surface roughness; however, particularly pronounced roughness could lead to local differences in the coat film adhesion to the metallic substrate and thus could promote corrosion on the metal. The present work deals with the influence of the galvanised surface roughness on the duplex system behaviour using Electrochemical Impedance Spectroscopy (EIS) technique. Three types of metallic surface conditions were employed: fresh galvanised steel (Ra = 0.9 µm) and aged galvanised steel with two weathering degress (Ra = 2.6 µm and Ra = 5.1 µm). The galvanised steel specimens were painted by brushing. The primer coat was based on a polyamine epoxy resin pigmented with aluminium to high solid content (82%). The average thickness was 100 µm. The topcoat was an environmentally friendly paint, based on a water-borne acrylic urethane resin and pigmented with Micaceous Iron Oxide (MIO); the solid content was about 65% and the average thickness was 50 µm. The impedance results are markedly different depending on the weathering degree. The results suggest that certain weathering degree is necessary for getting good protection efficiency.

References

- J.F. Malone. Mater. Perform., 31 (1992) 39.

- P.R. Seré, A.R. Armas, C.I. Elsner, A.R. di Sarli. Corros. Sci., 38 (1996) 853.

- A. Collazo, C. Pérez, M. Izquierdo, P. Merino. Prog. Org. Coat., 46 (2003) 197.

- B. del Amo, L. Véleva, A.R. di Sarli, C.I. Elsner. Prog. Org. Coat., 50 (2004) 179.

A. Petrenko

Akzo Nobel Dekor, Russian Federation

Title Poster

Optical and mechanical properties of the water-borne decorative coating influenced by the partial pigment substitution

Authors

G. Aleshina, A. Petrenko, A. Kehman, G.Ceytlin

Summary

In the process of improving coating cost-efficiency the partial pigment substitution with inorganic fillers remains a time-honoured but still most effective tool of reaching a broad price-property compromise, especially in the case of white architectural paints which are comparatively low demanding in their functional properties. In this work we report a systematic study of the partial substitution of the rutile titanium dioxide with a variety of calcium carbonates and silicates in preparation of the decorative white water-borne composition with the PVC of ca. 41%. Through detailed studies of the applied film gloss, hiding power and reflectance we estimated common optical effects of the filler particle size, morphology and concentration. The in-depth SEM analysis allowed speculations that filler influence on the optical properties of the paint film is mostly governed by the particle tendency to form agglomerates with titanium dioxide. It was also attempted to predict optical brightness of the filler pigment mixture using Kubelka-Munk theory and assuming K/S additivity. The calculations were in good agreement with experimental data. Mechanical stability of the filler containing coatings in comparison to that of the pigment only composition was estimated by testing scrub and weathering resistances. General conclusions were supported by the SEM micrographs.

Francesca Scaltro

Eindhoven University of Technology, TheNetherlands

Title Poster

Durability of Metal Oxide / Coating Interfaces

Authors

F. Scaltro, R. van Benthem, J. Laven, G. de With, J. Maas

Summary

Introduction

Good appearance and performance properties of a coating are very important. According

to this it is important that these qualities can be maintained intact as long as

possible for any coating that is intended for outdoor use.In most coating applications

interfaces exist between the organic binder material and metal oxide layers or

particles .It is well known that metal oxides can be highly photoactive and therefore

can play a major role in the degradation of coating layers they are in contact with.As

of degradation.

Material and Specimen Preparation

Crosslinked films of PEGDA (Mn ~ 475, 1% of photo-initiator) either or not with tin oxide

or antimony doped tin oxide nano-particles are applied on glass and silicon wafers.The

samples are exposed under UV light under different atmosphere conditions: dry air, dry

nitrogen, wet air and wet nitrogen.The samples have been monitored by means of

ATR-FTIR, transmission FTIR, UV-VIS, weight loss.

Results and discussion

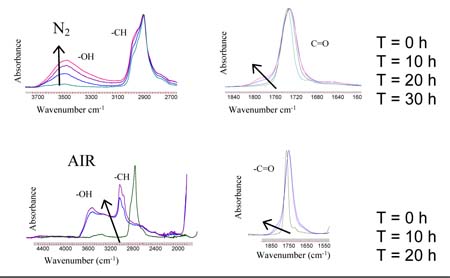

In fig.1 are shown spectra of crosslinked PEGDA without particles treated in dry

air and dry nitrogen.After irradiation the changes in the samples are

different. In the sample treated in N2 the OH- band (~3500 cm-1) increases in

intensity while for the samples treated in air the same band is subject to an

extensive broadening.Also in the area of the C=O band (1700 cm-1) there is the

appearance of shoulders at both samples treated in nitrogen or air. In the

sample treated in air there is also a pronounced shift of the maximum of the

C=O to lower wavelengths.The two different behaviors are related with the

possible reactions involved in the different conditions.

In nitrogen the system can undergo chain scission, hydrogen abstraction,

cross-linking. In air the radicals formed can react with oxygen and give peroxide

radicals. Once this species are formed a wide number of reactions can take

place.

The thickness of the “reactive layer” depends on how deep the

oxygen can penetrate in the system. The ATR-IR spectra clearly show the role of

oxygen in the degradation process however, the complicated structures involved

makes not easy to identify the exact chemistry involved. We have measured

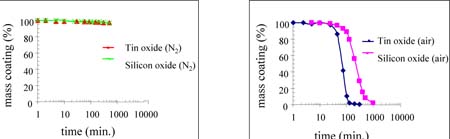

also the mass loss as a function of time of films made of PEG 3000 on

different metal oxide substrates and treated under different environmental

conditions. It is evident from figure 2a that there is a negligible weight

loss of PEG applied on flat substrates treated with UV light under dry

nitrogen. On the other hand samples treated in air lose weight easily after a

relatively short time: the coating on tin oxide much faster than the one on

silicium oxide.

The same experiments were performed under nitrogen with different humidity

levels. The weight loss rate in this case is found to be dependent on the

humidity level of the atmosphere. Higher humidity causes higher and faster weight

loss.

Conclusions

The presence of oxygen greatly affects the degradation process. Tin oxide

promotes photo-catalytic degradation resulting in a fast degradation.

Hydrolysis speeds up the degradation process in PEG films.

References

[1] J. F. Rabek, Polymer photo-degradation, mechanism and experimental

methods, Chapman & Hall

[2] O. Chiantore, L. Trossarelli, M. Lazzari,

Polymer 41 (2000) 1627-1668

Fig.1- ATR-FTIR of crosslinked PEGDA treated in N2 and in air after different exposure times.

Fig.2a - Mass coating (%) of PEG films treated in N2. Fig.2b- Mass coating (%) of PEG films treated in air.

Kurt P. Scott

Director, Research & Development, Atlas Materials Testing Technology LLC, USA

Title Poster

Innovation to Measure In Situ, Real-time Specimen Temperatures in Laboratory Weathering Devices

Authors

Kurt P. Scott, Zhijun Zhang, William Buttner

Summary

Consumers have a great deal of financial and emotional investment in the coatings applied to their automobiles and buildings, for example. The aesthetic and protective aspects of coatings are expected to endure for many years. Coatings manufacturers are constantly challenged to satisfy appearance demands, both for initial “showroom” appeal, as well as for the in-service maintenance of original appearance. Durability tests, and in particular, weathering tests, become a critical part of meeting the customer’s long-term expectations. Consequently, improvements in laboratory weathering instruments are mandatory to keep abreast of demands. In weatherabilty testing of coatings, the importance of light quality and specimen temperature is well understood and broadly documented in the literature. However, current laboratory instruments are incapable of directly providing this critical test information. This paper reports on innovations that enable weathering instruments to address this issue by making it possible to conduct tests in which test conditions and specimens are simultaneously characterized in unprecedented ways.

Daniela Senatore

Eindhoven University of Technology, The Netherlands

Title Poster

Encapsulation of powder coating cross-linker

Authors

D. Senatore, R. van Benthem, J. Laven, G. de With

Summary

Introduction

One of Powder Coating’s future trends is towards formulation of low curing

temperature coatings systems (lower than 140°C), that can be used for coating

heat-sensitive substrates like wood, MDF and plastics. However, a lower curing

temperature means that, without special tricks, such a powder coating formulation is not

stable regarding the storage at about 30°C and mixing temperature (typically at

70-110ºC). Our approach to overcome this paradigm is:

- to encapsulate one of the reactants of the powder coating formulationthe cross-linker

- to mix the encapsulated cross-linker with the resin, without breaking the capsules

- to de-encapsulate it as response of increasing the temperature, so as to allow molecular mixing of the ingredients and therefore cure the coating.

In the present work, preliminary results on the encapsulation step are reported.

Experimental procedure

Spray-drying technique was chosen, because it is fast, environment friendly and easy to

scale-up. The experiments were carried out using a Lab Spray-Drier , BÜCHI 290.

An oil-based cross-linker was emulsified in water by phase inversion in presence of a

nonionic surfactant. Such oil-in-water emulsion was mixed with an aqueous polymer

solution in ratio of 1:1. The droplet size distribution was measured by Light

Scattering (LS-Coulter 230). The mixture was spray-dried. The spray-dried

micro-particles were characterized by using SEM (JEOL-840A), LS (Coulter S230), DSC

(PE-Pyris1), TGA (PE-Pyris 6) and 1H-NMR (Varian 400MHz).

Results and discussion

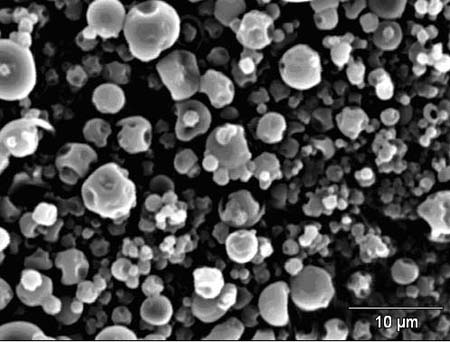

SEM analysis shows that the micro-particles are polydispersed and their surface

is free of cracks, although dents, due to shrinkage during drying, are present

(fig.1)

The polydispersivity of the micro- capsules is confirmed by LS analysis

which provides a particles size distribution centered around 6 µm. After

spray-drying, the micro-particles keep a residual amount of water of about 6%

on total powder weight, as confirmed by TGA measurements. Such water content

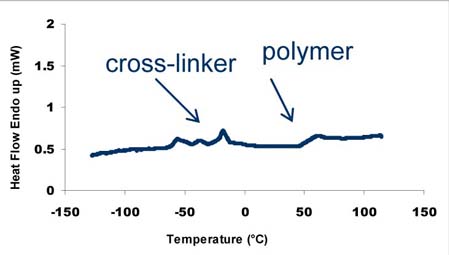

lowers the Tg of the polymeric shell to 56 ºC, according to DSC

measurements, which also shows the presence of thermal transitions (-70ºC

+10ºC), due to the cross-linker. Although, the exact nature of those

transition is not understood, DSC measurements prove the presence of the

cross-linker in the micro-particles (fig.2). 1HNMR analysis confirms that the

micro-particles contain the polymer , the cross-linker and surfactant. We

are working on evaluating the exact amount of encapsulated cross-linker.

References

Re M. “Microencapsulation by spray drying”, Dry Technology ,

16(6), 1195-1236 (1998) Thies,C. ”Encyclopedia of Chemical Science and

Engineering”; Wiley, NY,1987;vol 9, 2nd edition, pp 724-745

Fig.1 Spray-dried particles (SEM, 15kV)

Fig 2. Spray-dried particles (DSC, heating rate 10 ºC/min)

Willem Jan Soer

Eindhoven University of Technology, The Netherlands

Title Poster

Waterborne anti-corrosion coatings for magnesium surfaces

Authors

W. J. Soer, L. Klumperman, W. Ming, C.E. Koning, R. van Benthem

Summary

Magnesium alloys have a potential to be used as a weight-saving material in different applications. However, magnesium is very prone towards corrosion. In this project an organic coating is being developed that combines adhesion towards a metal substrate, barrier property for water and oxygen diffusion, and water repellency. Furthermore, the coating is water-borne, making it an environmentally friendly system. The polymer used in this system is poly(styrene-alt-maleic anhydride) synthesized by reversible addition-fragmentation chain transfer (RAFT) polymerization, allowing good control over the molecular architecture and molecular weight. The aqueous dispersions were obtained by partially ring-opening of the anhydride by NH3. These self-emulsifiable polymers can react with amine functional molecules, ultimately leading to hydrophobic imides. The material properties (Tg, hardness etc.) can be modified by introducing different groups on the anhydride. Furthermore, a difunctional amine can be used as a crosslinker. We found that with a specific diamine the minimal temperature at which the crosslinking of the polymer takes place could be lowered from 150 °C to 100 °C. The films that were formed from a dispersion containing 0.6 equivalent of amine (compared to anhydride) showed good chemical resistance, combined with good film forming properties and adhesion.

Di Wu

Eindhoven University of Technology, The Netherlands

Title Poster

Topologically structured, superhydrophobic thermoset coatings

Authors

D. Wu, W. Ming, R. van Benthem, G. de With

Summary

The development of superhydrophobic coatings (water contact angle above 150º) is driven by the promise of self-cleaning properties of such coatings, which are of enormous industrial potential. Nature has developed such self-cleaning surfaces, for instance the sacred lotus leaves. Generally, the super-hydrophobic surface is obtained by the combination of a hydrophobic surface and a high surface roughness. In our laboratory we have successfully developed low surface energy cross-linked films via surface segregation of fluorinated species during film formation. The addition of a small amount of fluorinated species could reduce the surface energy to 10-20 mN/m. In this project, we will impose a roughness in the scale of 0.1 – 1 μm to the surface, rendering the surface superhydrophobic. Correlations between surface wettability and surface chemical composition/topology will be established.

Ming Yuan

Eindhoven University of Technology, The Netherlands

Title Poster

Tunable conductivity levels in nano filler / polymer matrix composites

Authors

Ming Yuan, Jose Brokken-Zijp, Laura Huijbregts, Xiaoniu Yang, G. de With

Summary

Recently it has been shown that conductive filler/polymer matrix

nano-composites with a very low percolation threshold can be made when nano

particles such as electrical grade Carbon Black (CB), Phthalcon 11 are used as

conductive filler. In these and other conductive filler/polymer matrix composites

an initially steep increase in volume conductivity (σ) occurs at filler

levels just above the percolation level. At larger filler amounts the increase

in σ observed with a certain increase in filler concentration becomes lower

and levels off to a level (σmax) which hardly varies with filler amount

any more. The σmax values found in these composites are, generally, much

lower than the conductivity of the filler itself and may also depend strongly

on the choice of polymer matrix and processing conditions. These observations

are generally explained by pointing to the difference in conduction mechanism

and to the influence of isolating layers between the separate conductive

particles in the matrix. Unfortunately, experiments to prove these observed

variations in a (semi) quantitative way are lacking and possibilities to tune

this σmax to the level needed for specific applications are not known at

this moment.

The approach to follow for solving (part) of the above described problems is

to study the conduction mechanism of several well-defined conductive nano

filler/polymer matrix composites, to determine the main factors, which are

responsible for σmax in conductive filler/polymer matrix nano-composites

with a very low percolation threshold and find ways to tune this property so

that the level needed for a specifc application can be realized.

In our research, Phthalcon 11 is used as conductive filler since it can

offer a number of advantages above other conductive additives. We have

synthesized Phthalcon 11 with different particle sizes. In this poster the

synthetic routes to make Phthalcon 11 with different particle sizes as well as

the analysis of these particles will be discussed.