Speakers COSI 2007

- Professor Hans Juergen Adler, Technische Universitaet Dresden, Germany, Ultrathin layers as new concepts for corrosion inhibition and adhesion promotion

- Masahiko Akahori, Nippon Paint Co. Ltd, Japan, Radical shower technique using a remote plasma reactor

- Dr. Ingo Alig, Deutsches Kunststoff-Institut, Germany, Microcalorimetery for characterization of film formation and cure of coatings and adhesives

- Rong Bao, Fusion UV Systems Inc. USA, A new method of analyzing double bond conversion as a function of film thickness

- Keimpe J. van den Berg, AkzoNobel Car Refinishes, The Netherlands, Development of waterborne UV-A curable clear coat for car refinishes

- Professor Fred Brouwer, Van't Hoff Institute of Molecular Sciences, University of Amsterdam, The Netherlands, Real-time imaging of film formation using fluorescence spectroscopy

- Pascal Bru, Formulaction, France, Film formation of coatings studied by diffusing wave spectroscopy

- Professor Stuart Croll, North Dakota State University, USA, The interplay of physical aging and degradation weathering for two crosslinked coatings

- Michael Dornbusch, BASF, Germany, The use of modern electrochemical methods in the development of corrosion protective coatings

- Dr. Daniel de la Fuente, Max Planck Institute for Iron Research, Germany, Fundamental investigation on the stability of the steel/coating interfaces contaminated by submicroscopic salt particles

- Dr. Matthijs Groenewolt, BASF, CTR-Forsung, Germany, Innovative highly scratch resistant clear coats

- Marta Klanjsek Gunde, National Institute of Chemistry, Ljubljana, Slovenia, Dispersions of carbon black pigments in epoxy-based medium

- Tsuginori Inaba, Chuo University, Japan, Double bonding strength due to pre-treatment on metal surface for plasma spray with low pressure arc after grit blasting

- Rob Jans, Akzo Nobel Decorative Coatings Europe, The Netherlands, A new reactive diluent for decorative paints in view of 2010

- Professor Diethelm Johannsmann, Clausthal University of Technology, Spatially resolved maps the stress distributions occurring during drying of latex dispersions

- Dr. A.P. Kharitonov, Russian Academy of Sciences, Russia, Enhancement of commercial properties of polymeric articles by direct fluorination

- Dr. Sviatlana Lamaka, University of Aveiro, Portugal, Hybrid organic-inorganic sol-gel films as anticorrosion coatings for magnesium alloy AZ31B

- Sheun-Hwa Ma, Dupont, Germany, Structured acrylic polymers and their use in coating application

- Frank J. Maile, Merck, Germany, Orientation of transparent effect pigments and its influence on their appearance in polymer films

- Dr. Jacky Mallégol, Arcelor Research Industry Liege, Belgium, UV weathering of prepainted steel

- Professor Eva Malmström, KTH, Sweden, Covalent surface modification by controlled polymerization

- Professor Akira Matsumoto, Kansai University, Japan, Design of network polymers based on multivinyl crosslinking polymerization

- ir. Leendert Molhoek, DSM Resins, The Netherlands, Amorphous polyamide resins; new versatile binders for fast curing powder coatings

- Dr. Rolf Nothhelfer-Richter, Institut fur Polymerchemie, Universitaet Stuttgard, Germany, Investigations of the photocatalytic activity of pigments and pigmented organic coatings using the reactor method

- Dr. Jürgen Omeis, BYK-Chemie GmbH, Germany, The evolution of structured copolymers for coating applications

- Dr. Mark Plehiers, Sigma Coatings SA, Belgium, Synthesis of silyl acrylates for marine coatings

- Professor Wengfang Shi, University of Science and Technology of China, Hyperbranced acrylate prepolymers and their potential applications for UV powder coatings

- Willem Jan Soer, Eindhoven Univeristy of Technology, The Netherlands, Novel Crosslinking Systems for Surfactant-free Latexes Based on Maleic Anhydride Containing Polymers

- Milena Spìrková, Institute of Macromolecular Chemistry, Czech Republic, The view form the core onto the surface of self-assembled nanocomposite coatings

- Jeffrey M. Stubbs, DSM NeoResins, USA, The dynamics of morphology development in multi-phase latex particles

- Dr. Katia Studer, Ciba Speciality Chemicals Inc, Switzerland, Novel curing agents: thermal radical initiators as viable alternatives to peroxides

- Janice Tardiff, Ford Motor Company, USA, Automotive pretreatment - limitations of existing technology and enablers for future technology

- Nikhil Verghese, Dow Chemical Company, USA, The effect of rigid inorganic fillers on the mechanical and thermo-mechanical properties of epoxy thermosets: experimental and theoretical considerations

- Di Wu, Eindhoven University of Technology, The Netherlands, Nature-inspired Superhydrophobic Coating

Professor Hans-Juergen P. Adler

Institute of Macromolecular Chemistry and Textile Chemistry, Technische Universtitaet Dresden, Germany

Title lecture

Ultrathin layers as new concepts for corrosion inhibition and adhesion promotion

Author

Prof.dr. Hans-Juergen P. Adler

Abstract

It will be shown that ultrathin self-assembled layers of bifunctional

alkyl- spacered phosphonic acids on metal oxide surfaces can affect

adhesion promotion and corrosion inhibition. The results show that these

molecules are able to adsorb spontaneously onto the metal surface and

subsequently a structured molecular order is formed. We have synthesized

molecules with different spacer length, and different head groups, like

thiophene, pyrrole, dithienylpyrrol, and have copolymerized them

on the ultrathin surface layer.

The stability of metal/polymer interfaces is frequently determined by

electrochemical reactions. For ion-permeable coatings a diffuse double

layer is formed at the interface and all electrochemical reactions

including corrosion reactions are slowed down considerably. In the

presence of defects however ions will be able to diffuse along the

interface metal/polymer, the ionic strength at the interface increases

and the rate of electrochemical reactions is speeded up. As the results

of differering electrode kinetics between the intact interface and the

defect a galvanic element is set up, the defect being the anode and the

intact interface being the local cathode. At the cathode oxygen is

reduced and the reaction products may destroy the interface by an

oxidative attack or the substrate by electrolytic corrosion. In any case

deadhesion results.

We have developed a new release system for corrosion protection on

the basis of polypyrrole interface between the metal and an

organic coating system. The lecture will discuss some fundamentals of

the self-assembling process, the characterisation of the order in the

thin films, the electrochemically driven deadhesion reaction as well as

new technological concepts for the design of interfaces with superior

stability.

- Intelmann C.M., Rammelt U., Plieth W., Cai, X., Jähne E., Adler H.-J.P. (2006), Preparation of ultrathin polypyrrole films using an adhesion promoter, J.Solid State Electrochem, Vol 11, Nr.1(2007) 1-9

- Busch G., Jaehne E., Cai X., Oberoi S., Adler, H.-J. P. (2003): Ultrathin layers for adhesion promoters. Synthetic Metals 137, 871-872

- Pich A., Lu Y., Adler H.-J. P., Schmidt T., Arndt K.-F. (2002): Dispersion Polymerization of pyrrole in the presence of poly(vinyl methyl ether) microgels. Polymer 43, 5723 - 5729

- Mäge I., Jähne E., Henke A., Adler H.-J. P., Bram C., Jung D., Stratmann M. (1998): Self-Assembling Adhesion Promoters for Corrosion Resistant Metal Polymer Interfaces.Progress in Organic Coatings 34 , 1-12

Biography

Prof.Dr. Hans-Juergen P.Adler, TU Dresden, Institute for Macromolecular Chemistry and Textile Chemistry

- Born 1941 in Pirna, Saxony,Germany

- 1960 - 62: Vocational training as skilled worker for fiber spinning

- 1962 - 67: Studying Chemistry at Institute of Chemical Technology, Merseburg - Halle,Germany

- 1967 - 68: Scientific Assistant at Institute for Cellulose and Paper, Heidenau,Germany

- 1971: PhD at Technische Universität Dresden, in Macromolecular Chemistry, Germany

- 1971 - 85: Junior Group Leader at the same institute

- 1980 - 81: Postdoc at Institute for Macromolecular Chemistry, Prague, Czech Republic

- 1984: Habilitation for Macromolecular Chemistry and Textile Chemistry at TU Dresden

- 1985: Moving to Western Germany due to political reasons

- 1985 - 86: Research Manager at the Non-Wovens Company "Corovin" GmbH in Peine, Germany

- 1986 - 93: Research Manager at Akzo Coatings GmbH, Stuttgart, Germany

- in 1993: Research Manager at Lackfabrik Frei, Bräunlingen, Germany

- since 1993: Full-Professor and Director of the Institute of

Macromolecular Chemistry and Textile Chemistry, TU Dresden

- 1995-2007 Speaker of the Collaborative Research Project (SFB287) of the German Research Foundation (DFG) "Reactive Polymers in Inhomogeneous Systems, in Melts and at Interfaces" with 20 projects in 7 institutes in Dresden, Germany

- 2001-2004 Speaker of the European Graduated School "Advanced Polymeric Materials" (Prague, Czech Republic, Gliwice, Poland, Dresden, Germany) of the DFG

- Chairman of the expert group "Paints and Pigments" (APi) of GDCh (Society of German Chemists) 2000-2005

- President of the European Paint Association "FATIPEC" for the period 2001 - 2002 and Chairman of the XXVI International FATIPEC-Congress in Dresden (Sept. 9-11, 2002)

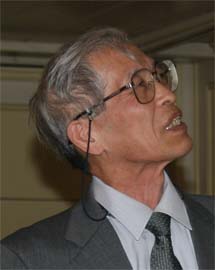

Masahiko Akahori

Nippon Paint Co., Ltd. R&D division, Tokyo Technical Center, Tokyo, Japan

Title lecture

A new test method for weatherability prediction of coatings: radical shower technique using a remote plasma reactor

Author

M. Akahori

Abstract

The exterior wall of

houses in Japan are refurbished or re-painted every 7-10 years due to

deteriorated coating conditions. In the point of the sustainable

housing, it is necessary to have a lifetime of 30 years. Although there

are several new durable paints now under development, it is difficult to

predict the durability during 30 years long with conventional

acceleration methods like the Super UV weather-test machine or the Xenon

machine.

A new test method for

weatherability prediction using a Remote Plasma Reactor has been

studied. We studied the degradation mechanism, by focusing on the fact

that exposure to radicals strongly influences the durability of

coatings. As a means of direct radical irradiation on the coatings, we

used a plasma-generating device. More specifically, in order to

investigate changes not only in color and gloss, but also surface

changes (SEM, and FTIR technique) through a down-flow type device

(Remote Plasma), the weatherability of enamel type coatings was studied.

This Remote Plasma method

showed that obtained results correlated with the outdoor exposure test

very well and especially acceleration behavior with test time was well

controlled. Moreover, this radical shower method can be applied for

other materials such as plastics and rubbers.

Biography

Masahiko Akahori

Nippon Paint Co., Ltd.

R&D Division

Japan

Educational Background

- 1987 Master Degree at Doshisha University

Work Experience

- 1987 - 1997 Research Chemist at Kanebo Co., Ltd.

- 1997 - Present: Research Chemist at Nippon Paint Co., Ltd.

- 2001- 2005 A member of National Project for Research and Development of House Technology Creating Life Values.

Research Interests

- Synthesis and applications of polymeric materials

- Development of adhesive and coating products

- Evaluation on weatherability and durability of polymer materials

Dr. Ingo Alig

Deutsches Kunststoff-Institut, Darmstadt, Germany

Title lecture

Microcalometry for characterization of film formation and cure of coatings and adhesives

Authors

I. Alig, D. Lellinger, H. Oehler, S.A. Adamovsky and Ch. Schick

Abstract

During film formation and/or cure of coatings and adhesives changes in

physical properties and chemistry of the material occurs. For material

development and characterization one has to consider the complex

interplay between drying, chemical reaction and/or vitrification. In

order to get a deeper insight into the mechanisms of film formation, it

is desired to monitor the changes of the physical properties in real

time.

Calorimetry, particularly differential scanning calorimetry (DSC),

belongs to the standard techniques for polymer characterization. DSC

measurements allow detecting glass and phase transitions,

melting/crystallization temperatures, specific heat and heat of reaction

or phase transitions for polymeric materials. With extensive laboratory

automation and use of combinatorial methods for material development,

there is an increasing interest in fast and/or parallelized methods for

industrial laboratories. To achieve high throughput calorimeters with

automatic sample changers has been developed [1]. Sensor arrays [2] are

not yet optimizes from a calorimetric point of view. However, one of the

limitations of calorimeters for characterization of coatings is the

difficulty to study films with open surfaces (e.g. drying of coatings at

defined relative humidity).

In this paper we describe a recently developed multi-channel

microcalorimeter with flat calorimetric sensors enabling such analysis

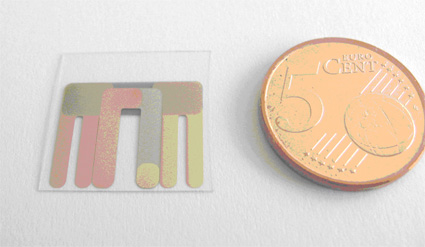

[3]. The sensors (Fig. 1) are based on commercial top glasses for

microscopy with heaters and thermocouples sputtered on upper and lower

side, respectively.

Fig.1: Calorimetric sensor for coatings (glass plate: 20x20 mm, thickness 150 μm).

The principle of the setup is similar to so-called thin film calorimeters [4-6], but the sensors are more robust and therefore easier to handle. The hard and software arrangement allows isothermal measurements and experiments with well defined cooling or heating rates. In all cases temperature-modulated experiments are possible. The setup allows to measures the real and imaginary part of the complex specific heat capacity (from amplitude and phase of the heat flow) and the latent heat due to drying or reaction. The setup has applied for monitoring of film formation from aqueous dispersions or solvent-based coatings, for curing of epoxies and acrylates, and IR curing of powder coatings.

References:

- M.F.J. Pijpers; V. B. F. Mathot; B. Goderis; et al. Macromolecules 35 (2002) 3601.

- J. Bennett, Proc. NATAS 2002 (2002) 150.

- AiF Project "Neuartiges Mikrokalorimeter zur Hochdurchsatzcharakterisierung von Polymermaterialien" (AiF Nr. 138 ZGB).|

- D. W. Denlinger; E. N. Abarra; K. Allen; P. W. Rooney; M. T. Messer; S. K. Watson; F. Hellman, Rev. Sci. Instrum. 65 (1994) 946.

- S. A. Adamovsky; A. A. Minakov; C. Schick, Thermochim. Acta 403 (2003) 55.

- http://www.xensor.nl/.

Curriculum vitae

Ingo Alig (Ph.D., D.Sc.)

Head of Department of Physics at Deutsches Kunststoff-Institut in

Darmstadt, Germany lecturer at Technical University Darmstadt

EDUCATION

Ph.D. 1983 in Physics, Technical University Merseburg Habilitation

(D.Sc.) 1988 in Experimental Physics

POSITIONS

- 1978-1991 Senior scientist at Department of Physics at Technical University Merseburg 1989-91 visiting scientist at Research Center of Crete/Greece, McMasters University Hamilton/Canada, Max Planck Institute for Polymer Science

- 1991-1993 senior scientist at the Institute for Physical Chemistry of University Köln

- 1993-now Head of department of Physics at the Deutsche Kunststoff-Institut and lecturer at Technical University Darmstadt

Rong Bao

Fusion UV Systems Inc. USA

Title lecture

A new method of analyzing double bond conversion as a function of film thickness

Authors

R. Bao and S. Jonsson

Abstract

A new method of analyzing a depth profile of double bond conversion as a

function of film thickness will be presented. By using a

combination of statistical calculation and FTIR, a new approach to

analyze the depth profile of conversion "layer by layer" in the

characterization of photo polymerization will be discussed.

Utilizing a formula (X1 + X2 +.... Xn) / n = Average conv. n = 1,2,3....

n: a number of layer (5 microns), an average conversion of any 5 micron

section can be calculated from prior 5 micron conversion and total

average conversion. More detail information of photo-polymerization,

such as the depth profile of conversion and a difference in conversion

between the top 5 microns and the bottom 5 microns in a 25 micron film

as a function of film thickness can be obtained.

This investigation will be accomplished using a variation of film

thickness, photo bleaching PhI (Irg. 819) and un-photo bleaching PhI

(Irg. 184) as well as the concentration of PhIs in the presence of air

and in absence of air. Some commercial formulations will also be

analyzed using this new approach. An influence of mixture of PhIs on the

double bond conversion at given depth of a cured film in a 25‑micron

film will be discussed. Results of analyzing double bond

conversion between traditional FTIR and the new approach (statistical

calculation / FTIR) will be compared.

Biography

Rong Bao got his Ph. D. for organic chemistry at Nankai University of P. R. China in 1988. From 1994 to 1996, Rong Bao worked at the Center for Photochemical Sciences in the Bowling Green State University of OHIO with Dr. Neckers as a research associate. Since 1996, Rong Bao joined the Fusion UV Systems, Inc as a research fellow for UV curing. His major research interest is photochemistry, photo polymerization and new UV lamp applications in the UV curing field. He has published more than 40 papers in different scientific journals and RadTech conferences.

Keimpe J. van der Berg

AkzoNobel Car Refinishes, Sassenheim, The Netherlands

Title lecture

Development of Waterborne UV-A curable clear coat for car refinishes

Authors

K.J. van der Berg, L.G.J. van der Ven, H.J.W. van den Haak

Abstract

The development of a waterborne UV-A curable clear coat for car refinish

application will be presented. The clear coat formulations are based on

specially developed acryloyl or maleimide functional polyurethane

dispersions. The functional PUR dispersions are characterized by a

relative low molecular weight, a low Tg, a high C=C functionality and an

optimized amount of poly(ethylene oxide). The characteristics are

necessary for optimal film formation and appearance (first two),

obtaining good film properties (third) and finally (fourth) for good

emulsification and sufficient cure at the surface (less influence of

oxygen inhibition).

The synthesis of the functional PUR dispersions and its performance in

clear coats will be discussed. Several aspects on film formation (cure

kinetics, evaporation speed of water) and film properties (durability,

influence of poly-EO on surface cure, physical and chemical properties)

will be discussed. The influence of film formation and amount of poly-EO

in the PUR dispersion on durability of the final clear coat has been

studied and has resulted in an optimal monomer composition of the

functional PUR dispersion

Biography

Dr. Keimpe van den Berg obtained in 1990 his PhD in Organic Chemistry at the University of Groningen (The Netherlands). In 1990 he started his career within Akzo as researcher, working on the development of new resins and crosslinkers for coatings. This work was carried out at Akzo Resins and Akzo Nobel Central Research. In 1997 Mr. van den Berg joined Akzo Nobel Car Refinishes where he worked at several positions within R&D. He currently holds the position of Manager New Technologies within Akzo Nobel Car Refinishes.

Professor Fred Brouwer

Van 't Hoff Institute of Molecular Sciences, University of Amsterdam

Title lecture

Real-time imaging of film formation using fluorescence spectroscopy

Author

F. Brouwer

Abstract

In recent years, improved instrumentation has allowed fluorescence spectroscopy to further extend its potential as an ultrasensitive detection method. Even individual molecules can nowadays be observed (almost) routinely. Using confocal microscopy, it is possible to determine a variety of fluorescence properties in a small volume element (typically an ellipsoid with a diameter of 300 nanometers and a length of 1-2 micrometers) inside a thin film within a second or less.One of the fluorescence properties that has not been extensively used in polymer chemistry is the solvatochromic shift of fluorescent dyes that have a nonpolar ground state and a very polar excited state. The emission spectrum of such a dye shifts to longer wavelengths with increasing polarity of the medium, provided that structural relaxation is possible on the time scale of the excited state lifetime (nanoseconds).In the lecture the application will be illustrated of the fluorescence solvatochromic shift and other fluorescence properties that allow separating the effects of polarity and mobility with high spatial and temporal resolution. Our first application will be the drying of latex films, labeled with fluorescent probe molecules.

Biography

Fred Brouwer studied physical-organic chemistry at Leiden University and

received his PhD there on a subject involving mainly organic

photochemistry and NMR spectroscopy. In 1987 he joined the staff of the

Organic Chemistry laboratory of the University of Amsterdam, working

initially with prof. Jan Verhoeven on photoinduced electron transfer and

related processes. Currently, he holds the John van Geuns chair in

Molecular Spectroscopy at the University of Amsterdam.

His research work involves photoinduced molecular motors, spectroscopic

studies of catalysis, and the development and application of fluorescent

probe molecules.

The application of fluorescent probes in polymer chemistry is the

subject of the presentation at COSI 2007.

Pascal Bru

Formulaction, France

Title lecture

Film formation of coatings studied by diffusing wave spectroscopy

Author

A. Brun, H. Dihang, L. Brunel

Abstract

The coating industry is facing nowadays a growth of environmental

regulations, an imposed substitution of suspected toxic components or

solvents and a constant need of improving performances. However, these

new formulations undergo new film formation processes, influencing the

coating performance and appearance.

We have studied the film formation process of several coating systems

using a new optical technology that gives a unique and simple

information. Based on Diffusing-Wave Spectroscopy, it allows a non

intrusive measurement of the drying on the appropriate substrate

(concrete, metal, plastic, wood…). The kinetics of film formation,

displayed in real-time, provide a new vision of the successive steps of

the mechanism taking place (evaporation, packing, interdiffusion…)

as well as accurate information on drying times such as open-time or

touch-dry time, for an in-depth characterization of the film formation

process.

Professor Stuart Croll

Department of Coatings & Polymeric Materials, North Dakota State University, Fargo, USA

Title lecture

The interplay of physical aging and degradation weathering for two crosslinked coatings

Authors

B.M.D. Fernando, X. Shi, S.G. Croll

Abstract

Polymer molecular relaxation, or 'physical aging', is a very important

influence on permeability and mechanical properties of any polymer below

its glass transistion. 'Physical aging' occurs as even an unstressed

polymer gradually relaxes towards its equilibrium conformation. This

happens over periods much longer than the typical cycle of an

accelerated weathering test, thus important properties of a polymeric

coating may be affected by the difference in frequency between natural

and artificial exposures, in addition to other factors.

Further, 'physical aging' is affected by chemical changes to the polymer

network caused by the degradation during a weathering exposure. In this

investigation, purely physical aging was compared with the effect of

concurrent chemical degradation by measuring 'enthalpy recover' and

mechanical stress relaxation at a variety of temperatures and at various

stages during accelerated weathering exposure.

The effect of physical aging was quite apparent in both an

epoxy-polyamide coating and a polyester-urethane coating. Changes in

physical aging behaviour during degradation were different for the two

coatings, which points to further reasons for discrepancy between

accelerated weathering and natural exposure.

Biography

Stuart Croll gained a degree in physics from the University of London a long time ago, then completed a doctorate in polymer physics at the University of Leeds. He first worked in England, then moved to Canada where he studied the residual stresses in coatings that arise during curing. After a career in the US coatings industry and its suppliers, wherein he occasionally managed to do research on film formation, Dr. Croll joined the Department of Coatings and Polymeric Materials at North Dakota State University in 2000, where he is now the Chairman of the Department. His research interests are in the weathering durability of polymers and coatings, colloidal stability, phase separation and renewable resources for coating technology.

Michael Dornbusch

BASF Coatings, Germany

Title lecture

The use of modern electrochemical methods in the development of corrosion protective coatings

Author

M. Dornbusch

Abstract

The development of corrosion protective coatings will always remain a

challenge in industrial research. The application of

electrochemical methods within an industrial development is an

innovative tool to expedite the development of coatings.

The electrochemical impedance spectroscopy and the Scanning Kelvin

Probe with height control as two out of numerous methods are in the

focus of the presentation. With these methods the corrosion mechanism

and interaction between the pre-treatment and different

electrodeposition coatings could be clarified. Diffusion rates, swelling

and network density of mono and four layer coatings enhance the

comprehension of current coating products. and provide useful knowledge

for the development of new coating systems.

Furthermore the description of mechanical effects is possible allowing a

deduction of consequences for the corrosion mechanism.

Scientific cognition in industrial R&D based on results out of

these modern electrochemical methods will increase significantly

fundamental understanding and effectively speed up the progress of

corrosion protective coatings development.

Biography

10/1992 - 09/1997

Study of Chemistry at the "Heinrich-Heine-University of Düsseldorf" with

the focus of dye and photochemistry, Diploma: "Synthesis of modified

heterocyclic Retinal analoga"

01/1998-01/2001

PhD at the Institute of Organic und Macromolecular Chemistry at Prof.

Dr. H.-D. Martin at the "Heinrich-Heine-University, Düsseldorf".

Topic: "Synthesis of five-ring-membered heterocyclic Retinoids as

Chromophors for the Bacteriorhodopsin" (Model for the electronic

interaction of heterocyclic Retinoids with the protein pocket)

04/2001-09/2001

Research, production and sales responsibility at the Solvent-Innovation

GmbH, Aachen Development of new ionic liquids and process optimisation

10/2001-09/2003

Project leader at the "Max-Planck-Institute for iron research",

Düsseldorf

"Development of alternative processes for the Zn-Phosphatation for

automotive application" Clarification of the reaction mechanism from

converion baths with the substrate

10/2003 since now

Leader of the Corrosion protection basics lab at the BASF Coatings AG,

Münster

Dr. Daniel de la Fuente

Max Planck Institute for Iron Research, Dusseldorf, Germany

Title lecture

Fundamental investigation on the stability of the steel/coating interfaces contaminated by submicroscopic salt particles

Authors

D. de la Fuente and M. Rohwerder

Abstract

The presence of hydrosoluble species, mainly chlorides and sulphates, at

the metal/paint interface promotes osmotic blistering of the coating and

underfilm metallic corrosion when the concentration of the soluble salts

exceeds a critical level. Loss of adhesion and cathodic disbondment can

be also consequences of the presence of soluble salts. These processes

can lead to the deterioration of the paint system in a very short period

of time. However, since the interface is not easily accessible by

experiment, not much is known about interfacial structure, reactions and

the processes causing degradation. Scanning Kelvin Probe (SKP) is an

ideal tool for the in situ monitoring of the degradation processes at

the buried interface. On the other hand, for an in-depth understanding

it is important that the superposition of the effects of all different

parameters involved can be disentangled. Hence, it is important to

design experiments focussing on individual aspects of the complex

system.

In the present paper, a study of the fundamental aspects of the

stability of the contaminated buried steel/coating interfaces, specially

focused on the initial stages of blistering and underfilm corrosion, has

been carried out. Results of the characterization study performed with a

height-regulated SKP (HR-SKP) on surfaces contaminated at the interface

by different salt concentrations with well defined crystal size and

distribution are shown.

Biography

Dr. Daniel de la Fuente worked at the Spanish National Centre for Metallurgical Research (CENIM) from 1998 to 2006 in the Atmospheric Corrosion and Protection Group directed by Prof. Morcillo. Specialised in metallic corrosion and protection, in the research areas of corrosion in natural environments and protection by coatings, in 2006 he was awarded with an Alexander von Humboldt Fellowship and he joined the group of Dr. Michael Rohwerder at the Max-Planck-Institute for Iron Research in Düsseldorf (Germany). At present he is a post-doctoral researcher in this institute carrying out a project on the topic of Degradation Mechanisms of Metal/Polymer Interfaces Contaminated by Soluble Salts. He is co-author of numerous scientific publications in specialised international journals and he has also presented papers in the most important national and international Congresses on the speciality.

Dr. Matthijs Groenewolt

CTR- Forschung, Germany

Title lecture

Innovative highly scratch resistant clear coats

Author

M. Groenewolt

Abstract

The design of scratch resistant clear coats is still a highly desired

goal in modern coatings technology. Especially in automotive

applications, where coatings have to fulfil several demanding customer

needs simultaneously, this goal is rather challenging. For example the

coating has to be very resistant against each kind of chemicals, very

scratch resistant (=often brittle) and long term stable (=often

flexible) at the same time.

Several chemical approaches can be utilized to reach scratch resistance

of the coating, e.g. the use of nano-particles or the synthesis of

an extraordinary high crosslinking density (XLD). An innovative approach

based on a new crosslinking technology will be introduced.

It will be illustrated, that this new coating’s design provides

high crosslinking density and long term stability simultaneously.

Theoretical and experimental investigation on the degree of crosslinking

found a good correlation. In addition the nano structured features of

this system could be uncovered.

Sustainable strategies to overcome the already mentioned common problems

of highly crosslinked systemes with long term durability will be

demonstrated.

Biography

Current position: Head of the nanotechnology lab at BASF Coatings AG, Münster

Short CV Dr. Matthijs Groenewolt

- 97-01: Studies of chemistry; LMU Munich

- 00: Advanced organic studies; Universtiy of Lund, Sweden

- 01-02: Diploma thesis; Max-Planck-Institute of quantum optics, Munich

- 02-05: PhD thesis; Max-Planck-Institute of colloids and interfaces, Potsdam

- 05-present: Head of the nanotechnology-lab at BASF Coatings AG, Münster

Dr. Marta Klanjsek Gunde

National Institute of Chemistry, Ljubljana, Slovenia

Title lecture

Dispersions of carbon black pigments in epoxy-based medium

Author

M. Klansjek-Gunde, N. Haubtman, M. Macek, M. Bester Rogac

Abstract

Epoxy-based nanocomposite systems are suitable for sensing materials in

capacitive chemical sensors. Suitable nanoparticles are dispersed

carefully within the epoxy-based photoresist in order to change the

electrical properties of the composite. This way the sensing material

can be optimized regarding to the chemical nature of analyte and its

dielectric constant.

Some types of carbon blacks have been applied. They are characterized by

different primary particle sizes, specific surface area and specific

resistance. The state of the dispersion of solid particles within the

polymer in the liquid state and the properties of the composite which is

formed after the UV-exposure was controlled together with the phenomena

occurring on the interaction zone between nanoparticle surfaces and

polymer matrix. Several properties of the prepared dispersions of carbon

black and condensed nanocomposites such as chemical composition, state

of the dispersion, viscosity of the liquid phase and resistivity were

considered. For the purposes of analysis, all the advantages of the

Fourier-Transform Infrared Spectroscopy and Scanning Electron Microscopy

were taken into account

Biography

Dr. Marta Klanjsek Gunde finished her PhD in physics at the University of Ljubljana, Slovenia. She is working as research associate at the National Institute of Chemistry in Ljubljana, Slovenia and has about 25 year experiences in material research. She is experienced in optical and vibrational analysis of infrared spectra of single crystals and thin solid films, including fundamental issues such as coupling of elementary excitations, lattice defects and dopant inclusions. She developed full optical analysis of IR spectra of semiconductor materials in bulk and thin film forms. During the past years she was extending her research on the optical effects in pigmented coatings where she apply scattering theories as well as colorimetric methods. Currently she is leading the research project on nanocomposites where the knowledge from microelectronic applications, that she was working with her colleague in the past, is connected with experiences in pigmented coatings.

Professor Tsuginori Inaba

Chuo University, Tokyo, Japan

Title lecture

Double bonding strength due to pre-treatment on metal surface for plasma spray with low pressure arc after grit blasting

Authors

Masayuki Hara, Yuya Kubo, Koji Ogura, Toru Iwao, Shogo Tobe, Tsuginori Inaba

Abstract

Cathode spots of a low-pressure arc can remove oxide layers and

evaporate impurities on metal surfaces. Removal of the oxide layer using

cathode spots is expected to solve recent obstacles due to chemical and

mechanical cleaning methods. Various phenomena of cathode spots have

been investigated for pre-treatment of atmospheric pressure plasma spray

(APPS). This study treated the surface shapes of oxide and non-oxide

samples using a composite pre-treating method: cathode spots after grit

blasting. In addition, the samples are compared with conventionally

treated cathode spots and mechanical blasted surfaces.

Results show that roughness on the sample surfaces becomes higher in

concomitance with the initial oxide layer thickness. This fact reveals

the factors those dominate bonding strength on the pre-treated surface

using cathode spots of a low-pressure arc. Bonding strength becomes

higher in relation to the arithmetical mean height of the surface

roughness caused by the initial oxide layer thickness. Bonding strength

is higher when the mean spacing of profile irregularities is narrower.

The bonding adhesive strength after treatment using cathode spots after

grit blasting is greater than 90 MPa. However, cathode spot treatment

must be limited not to destroy the projection formed by melting after

grit blasting in an arc time up to 5s.

Biography

Tsuginori Inaba received the B. Sc., M. Sc. From Nagoya Institute of

Technoloty, Nagoya, Japan, in 1966 and 1968, respectively. He received

the Ph.D. degrees in engineering from Nagoya University in 1971. All in

Japan.

Currently, he is Professor and Director of Thermal Plasma Research

Center at Chuo University, Tokyo, Japan. In 2004 he worked at Minnesota

University and Muenchen Technical University. During 1978 and 1979, he

was a Guest Professor at Technical University Braunschweig in West

Germany. From 1971 to 1994 he worked at Central Research Institute of

Electric Power Industry (CRIEPI). From 1959 to 1965, he worked at

Mitsubishi Electric Corp. He joined Adeka Agath Chemical Co.Ltd. in

1965. All in Japan.

Dr. Inaba now heads a Technical Committee on Static Equipment of IEE

of Japan and the IEC TC32, SC32A and SC32B National Committees on Fuses.

In 1976, 1988, and 1995, he received IEE Japan awards for best articles.

In 1994 the IEE Japan best author award and in 2005 the IEE Japan best

author group award. He is a member of IEE of Japan, the Society of

Cryogenic Technologies in Japan, the Japan Institute of Metals(JIM),

IEEE in U.S.A. and so on.

Rob Jans

AkzoNobel Decorative Coatings Europe, The Netherlands

Title lecture

A new reactive diluent for decorative paints in view of 2010

Authors

R.J.F. Jans, R.P. Klaasen, M. Meijer, H. Kelders, A. Lansbergen, M. Spierenburg

Abstract

Due to the upcoming legislation on VOC in 2010 the use of volatile compounds in Decorative paints will be further limited. This urges to develop new ways in formulating coatings. One way of achieving a lower VOC level is to make use of so-called reactive diluents. In contrast to normal solvents these diluents remain in the paint film and react with the alkyd binder. In this lecture the prerequisites for a good reactive binder are addressed. Moreover, the development of a suitable Reactive Diluent, matching these prerequisites is described. A special category of so-called Knoevenagel adducts, shows excellent performance. This performance is presented here. Also the effects of these diluents in the paint and paint film are described.

Biography

Education

- 1981-1985 Universiteit van Amsterdam

- PHD: Syntheses and Reactivity of Metal-sulphine Complexes, 1988

- 1974 - 1981: Vrije Universiteit

- Master Study: Inorganic chemistry

- Minor I: Organic Chemistry

- Minor II: Chemistry of Food and nutrition

- 1968 - 1974: Secondary school: Pius X College, Atheneum B

Professional career:

- 1986: Sikkens BV, Research chemist Automotive Support

- 1993: Manager Support and Development of Decorative paints

- 2002: Manager Technology Centre Decorative paints

Professor Diethelm Johannsmann

Institute of Physical Chemistry, Clausthal University of Technology, Germany

Title lecture

Spatially resolved maps the stress distributions occuring during drying of latex dispersions

Authors

K. von der Ehe, A. Turshatov, J. Adams, D. Johannsmann

Abstract

The talk shows the results of spatially resolved stress measurements

on drying latex films. The sample is cast onto a flexible membrane,

which warps under the influence of stress. The back of the

membrane is used as a mirror. Imaging some kind of regular pattern

across this distorted mirror, one can infer the stress distribution from

the distortions of this image.

We find that the stress usually is laterally homogeneous in the initial

phase of drying. As the drying front proceeds from the rim to the

center of the drop, material moves from the center to the rim.

This movement is caused by a stress gradient. The flow is

analogous to Marangoni flow but the stress is not caused by surface

tension, but rather by the bulk film. The final droplet usually is

thicker at the rim than in the center. Also, the residual stress

is largest at the rim. In cases where the films crack during

drying, inhomogeneous stress distributions are often seen before the

film actually cracks. These results suggest that Marangoni flow

can lead to an instability which precedes cracking.

Measurements of non-radiative energy transfer (NRET) between donor and

acceptor fluorescent molecules located on different particles complement

these studies. NRET measurements give access to the amount of

polymer interdiffusion and the concommittant increase in mechanical

strength.

Biography

Education and Professional Experience:

- 1986 Degree in Physics from Heidelberg University

- 88 - 91 PhD-thesis at the MPI for Polymer Research, Mainz

- Awarded the "Prof.-Dr.-Jürgen-Geiger-Preis"

- 91 - 93 Feodor-Lynen-Fellow, UC Berkeley

- 93 - 02 Senior Research Fellow at the MPI for Polymer Research, Mainz

- since 02 Professor of Physical Chemistry at Clausthal University of Technology

Research Interests:

Polymer Coatings, Acoustic Sensors, Microtribology, Surface-attached

Hydrogels

Dr. Alexander P. Kharitonov

Institute of Energy Problems of Chemical Physics (Branch) of the Russian Academy of Sciences, Chernoglolovka, Moscow Region, Russia

Title lecture

Enhancement of commercial properties of polymeric articles by direct fluorination

Authors

A.P. Kharitonov, L.N. Kharitonova, R. Taege, G. Ferrier

Abstract

Results of more than 25-years research of both fundamental features of

the direct fluorination of polymers (i.e. treatment of polymer surfaces

by gaseous fluorine and its blends), physical-chemical properties of the

surface modified layer and study of the possibilities to enhance gas

separation properties of polymeric membranes and modules, barrier

properties of polymeric articles and mechanical properties of

polymer-polymer fiber composites are reviewed.

More than 20 various polymers (polyolefines, polycarbonates, polyimides,

polysulfones, simple and complex polyethers, phenyl-containing polymers,

silicon-containing polymers, polyacrylates, co-polymers, etc.) where

studied. The following methods where used: FTIR spectroscopy,

spectroscopy in the visible and near UV region of spectra,

refractometry, electron microscopy, gas-chromatographic and volumetric

measurement of transport properties of polymeric membranes, measurement

of the surface energy, measurement of the permeability of liquids

through polymer films, “in situ” interference method of investigation of

the kinetics of formation of fluorinated layer, method of measurement of

the density of fluorinated polymer layers (over 0.5-10 micrometer

range).

The influence of treatment conditions (composition and pressure of the

fluorinating mixture, fluorination duration and temperature) on the

polymer chemical composition, thickness of fluorinated layer, density,

refraction index, surface texture and surface energy were investigated.

Kinetics of formation and termination of radicals, formed inside the

fluorinated layer, was studied. A theoretical model, describing the

kinetics and mechanism of the direct fluorination of polymers, has been

developed on the basis of obtained data.

A method to enhance the barrier properties of high density polyethylene

with respect to petrol-methanol and petrol-ethanol mixtures has been

developed. Direct fluorination was successfully applied to enhance

separation properties of polymer flat membranes and hollow fiber

membrane modules. Fluorine treated membranes have enhanced gas

separation selectivity, e.g. selectivity of He/CH4 and h5/CH4 separation

can be increased by a factor of several tens times as compared with

starting membrane. Fluorination of Kevlar fiber enhanced the thermal

stability and tensile strength of polymer-Kevlar fiber composite.

Biography

EDUCATION

- Master of Sci. in physics in 1973, Moscow Institute of Physics and Technology, Department of the Molecular and Chemical Physics, the USSR.

- Ph.D. (physical-mathematical sciences) in 1979.

- Doctor of Sciences (physical-mathematical sciences) in 2006.

POSITIONS AND DUTIES

- 1967-1973, 1973-1976- student and post-graduate student of the Moscow Institute of Physics and Technology (the USSR);

- 1976-1987- engineer, junior research scientist and senior research scientist, head of group at the Institute of Chemical Physics (Division) of the USSR Academy of Sciences;

- 1987-2005- senior research scientist at the Institute of Energy Problem of Chemical Physics (Branch) of the Russian Academy of Sciences.

- 2005-present- leading research scientist at the Institute of Energy Problem of Chemical Physics (Branch) of the Russian Academy of Sciences, Chernogolovka, Moscow Region, 142432, Russia.

RESEARCH ACTIVITIES

- 1978-present- fluorine chemistry, including:

- 1984-present- the modification of polymers by the direct gas phase fluorination (kinetics and mechanism of the formation of the fluorinated layer on the polymer surface, structure of fluorinated polymers, introduction of functional groups into the polymer structure, gas transport properties of fluorinated polymer membranes and their gas-separation properties, kinetics and mechanism of elementary stages of the chain process of the direct fluorination). Enhancement of gas separation properties of polymer membranes, barrier properties of polymer articles, adhesion properties pf polymers, mechanical and thermal properties of polymer composites.

- 1994-present- fluorination of fullerenes, nanoparticles and nanotubes.

- 1978-1984- the kinetics and mechanism of gas-phase elementary reactions in systems including fluorine, chlorine, oxygen, hydrogen etc..

- 1988-present- investigation of the physical-chemical properties of high-temperature superconductors subjected to the cooperative action of fluorine and ionizing radiation.

- 1973-1980- chemical and photo-recombination lasers.

Dr. Sviatlana Lamaka

University of Aveiro, Dep. Ceramics and Glass Eng., Aveiro, Portugal

Title lecture

Hybrid organic-inorganic sol-gel films as anticorrosion coatings for magnesium alloy AZ31B

Authors

S.V. Lamaka, A.F. Galio, M.L. Zheludkevich, L.F. Dick, I.L. Muller, M.G.S. Ferreira

Abstract

The main reason preventing enhancement of using of light magnesium

alloys in construction applications is their high corrosion

susceptibility. This work aims at creation and investigation of new

anticorrosion coating systems for magnesium alloy AZ31B.

The hybrid organic-inorganic sols were prepared by copolymerization of

3-glycidoxypropyltrimethoxysilane (GPTMS), titanium alcoxides and

additives which provide corrosion protection specifically for magnesium

alloy. The average thickness of sol-gel coatings, which were produced by

simple and fast dip-coating procedure, is 2 micron. However, even such a

thin sol-gel coating exhibits excellent adhesion to the substrate and

prevents corrosion attack of 3% sodium chloride solution for 2 weeks of

standard immersion test. No pitting appeared on the surface of coating

and magnesium substrate.

The morphology and the structure of the sol-gel films were characterized

with SEM/EDS and AFM techniques. Corrosion behaviour of AZ31B substrates

pre-treated with sol–gel derived hybrid coatings were tested by

Electrochemical Impedance Spectroscopy and Scanning Vibration Electrode

Technique. Different composition of sol-gel systems show enhanced

long-term corrosion protection of magnesium alloy.

Biography

Currently Sviatlana Lamaka is a post-doctoral researcher at the

University of Aveiro in Portugal. She made her PhD in Analytical

Chemistry at Belarusian State University in Minsk, Belarus. There she

has been teaching courses on General Analytical Chemistry and

Physical-Chemical Methods of Analysis.

Recently she has joined group of professor Mario Ferreira in Aveiro.

Currently her main interests are in the fields of Nanostructured

coatings for corrosion protection with self-healing ability; Organic

inhibitors for protection of aluminium alloys and Modification of AFM

probes.

Sheau-Hwa Ma

Dupont, Germany

Title lecture

Structured acrylic polymers and their use in coating applications

Authors

Sheau-Hwa Ma

Abstract

There has been very high level of interest in the area of controlled free radical polymerization from both the academics and the coating industry, and significant advancement has been made in areas like ATRP, NMP, and RAFT over the past years. These techniques have provided tools to more precisely control the size/MW and the shape of the polymer and given the ability to choose and precisely place the functional groups to derive unique properties. This has added a new dimension to coating formulation, which may enable us to better meet the increasing demands from both the customers and the environmental regulations. Examples will be discussed in more details.

Biography

Sheau-Hwa Ma, a native of Taiwan, graduated from National Cheng-Kung University, Taiwan, with a BS degree in Chemistry in 1974. She then went on to the United States and obtained her Ph.D. degree in the field of Physical Organic chemistry from Boston University in 1979. After a postdoctoral research program at Princeton University, she joined E.I. DuPont Company in 1981. Over the years she has worked for several business units and is currently associated with the Performance Coatings Business Unit at the Marshall Research Lab, Philadelphia, Pennsylvania. Her research interests include living polymerization, controlled free radical polymerization, structured acrylic polymers, pigment dispersant and dispersions, both waterborne and solvent borne systems, and their applications.

Dr. Frank J. Maile

Merck KGaA, Darmstadt, Germany

Title lecture

Orientation of transparent effect pigments and its influence on their appearance in polymer films

Authors

Dr. F.J. Maile, Dr. P. Reynders, Dr. M. Rosler

Abstract

Driven by trends in fashion, automotive and other consumer markets,

special effect pigments have a growing economic significance and can be

found in various industrial products and end-user applications. The main

effects are an angle-dependent colour and decorative textures.

The colouristic effects of pearlescent effect pigments rely on the

interplay between absorptive and interference effects in layered

structures deposited on platelet-shaped core particles. Their

performance of course depends much on the quality of these layers, but

the nature of the substrate cores - their chemistry, shape, size, size

distribution, and flawlessness - is also extremely important.

After an introduction to substrate-based effect pigments, we will

present the newest developments and production technologies in this

area. The relation between orientation of the pigment platelets and the

appearance of the final composite film will be discussed for different

polymer and lacquer films.

Biography

Dr. rer. nat. Frank J. Maile is a Senior Manager within the PLS

(Performance & Life Science Chemicals) department at Merck KGaA

Darmstadt, Germany.

After graduating in chemistry from the university of Stuttgart, Germany

he worked at the research center for pigments and paints (FPL e.V.) in

Stuttgart, Germany and the institute of applied macromolecular chemistry

at the university of Stuttgart for his doctorate (with Prof. Dr. Claus

D. Eisenbach). For his PhD thesis ("new application areas of SRET -

Scanning Reference Electrode Technique") he received the FARBE &

LACK (of Vincentz Verlag) and APi award (of the German Society of

Chemists, GDCh). Within the business unit PLS/PIGM/Coatings he is

responsible as a group leader for the technical service

(industrial/automotive paint customers) for effect pigments. Ca. 40

publications/conference contributions.

Jacky Mallégol

Arcelor Research Industry Liège, Belgium

Title lecture

UV weathering of prepainted steel

Author

J. Mallégol

Abstract

One of the main markets for prepainted steel is the construction market,

which implies an outdoor weathering. Guarantees for the prepainted

steels mainly include the corrosion resistance of panels and the

aesthetics of paint (colour change and gloss retention).

We will present in this lecture some examples of our studies carried out

in the field of durability (and more especially in UV weathering) of

prepainted steel, with a focus on: correlation between UV weathering in

accelerated lab tests and in natural outdoor exposure relationship

between the UV degradation of paint and the corrosion resistance of

prepainted steel.

The UV weathering of a first selection of painted panels has been

performed, with various UV testing devices (WOM, QUV and SEPAP). The

photo-degradation has been followed with FTIR spectroscopy,

micro-hardness, UV-visible spectroscopy, colorimetry and gloss

measurements. The influence of the water (hydrolysis of oxidation

products) has been included in the tests that were carried out without

condensation/aspersion phase. The test fitting in the best way the

natural evolution up to 10 years in Hendaye (South West of France) has

been determined, and then applied on a larger series of samples for

validation.

For investigating the correlation between paint photo-degradation and

corrosion resistance of prepainted steel, panels have been exposed to UV

irradiation prior to salt spray exposure. The modification of the

barrier effect has been determined with EIS, while measuring the

oxidation profiles in the paint (FTIR spectroscopy). The blistering on

the overall surface during salt spray exposure has thus been reproduced

on some panels where the paint had a very poor resistance to UV

weathering, and exhibited pronounced oxidation profiles.

Professional CV of Jacky Mallégol

Dr Jacky Mallégol holds a Chemical Engineering Degree and a Ph.D. in Physical Chemistry from the University of Clermont-Ferrand in France. His Ph.D. research dealt with the curing and degradation mechanisms of oil-based paints. During a first postdoctoral training at the National Research Council of Canada in Ottawa, he worked on polyethylene packages and their stability upon gamma-irradiation. He then started in 2000 a second postdoc at the University of Surrey in England, working in collaboration with UCB Chemicals on film formation in water-based pressure-sensitive adhesives. In 2002, Dr Jacky Mallégol joined a major research centre of the Arcelor group located in France, working in the fields of organic coatings adhesion and of UV curing. In 2004, he has moved to Arcelor Research Liège (Belgium), in the Organic Coatings department, where he is leading projects dealing with surface functionalities, new ways of curing and UV weathering of prepainted steel.

Professor Eva Malmström

KTH, Department of Fibre & Polymer Technology, Stockholm, Sweden

Title lecture

Covalent surface modification by controlled polymerization

Authors

Eva Malmström, Josefina Lindqvist, Daniel Nyström, Hanna Lönnberg, Linda Fogelström, Anna Carlmark.

Abstract

Surface confined polymerizations have become readily accessible by the development of controlled polymerization techniques, such as atom transfer radical polymerization (ATRP). ATRP allows for the concurrent growth of many adjacent chains with appropriate control over chain ends, molecular weight and molecular weight distribution. Fibres from natural sources, such as cellulose, are receiving increasing interest. To be successfully used in composites for instance, the fibers often need to be surface modified in order to reduce water uptake and enhance the compatibility with the matrix. This can be accomplished by grafting the fibre surface with polymers. Both ATRP of vinyl-type monomers as well as ring-opening polymerization of cyclic monomers can be used. By the appropriate choice of monomers it is possible to transform highly hydrophilic biofiber-based substrates into hydrophobic or even superhydrophobic surfaces.

Akira Matsumoto

Department of Applied Chemistry, Faculty of Engineering, Kansai University, Suita, Osaka,Japan

Title lecture

Design of network polymers based on the mechanistic discussion of multivinyl crosslinking polymerization

Author

A. Matsumoto

Abstract

We have been concerned with the network formation in the free-radical

crosslinking polymerization and copolymerization of multivinyl monomers,

especially those including diallyl esters and dimethacrylates, by

focusing our attention on the mechanistic discussion of the deviation

from Flory-Stockmayer (FS) gelation theory. There are two extreme

crosslinked polymers as an ideal network polymer governed by FS theory

and a microgel greatly deviated from the theory.

We extended the above mechanistic discussion to the development of novel

network polymers; (i)amphiphilic network polymers consisting of short

primary polymer chains and long crosslink units with opposite

polarities, (ii) semi- or full-IPN formed via the topological crosslink

between liner polymer and net polymer or net polymers having loop

structures as extreme precursors of microgel-like network polymers with

oligomeric primary polymer chains, (iii) inhomogeneous network polymers

having reactive crosslinked polymer nanoparticles, i.e.,

pseudo-microgels, as crosslink sites, and (iv) network polymers with

abundant dangling chains consisting of centipede-type primary polymer

chains originated from multiallyl crosslinking polymerization.

Biography

Akira Matsumoto

Present Position: Professor, Department of Chemistry and

Material Engineering, Faculty of Chemistry, Materials and

Bioengineering, Kansai University

Education:

- 1964, Bachelor of Engineering (Department of Applied Chemistry, Faculty of Engineering, Osaka University)

- 1972, Doctor of Engineering (Osaka University)

Employment:

- 1964, Instructor, Department of Applied Chemistry, Faculty of Engineering, Kansai University;

- 1977, Lecturer;

- 1983, Associate Professor; 1990-Professor

- 1977 Oct. - 1978 Mar., AdjunctPostdoctoral Associate, University of Florida, U.S.A.

- 1984 Jun., Visiting Scholar, Peking University, China

- 1985 Apr. - 1986 Mar., Visiting Associate Professor, University of Florida, U.S.A.

- 1988 Sep. & Oct., Visiting Professor, Catholic University of Leuven, Belgium

Research Interest:

- Free-radical crosslinking polymerization, Cyclopolymerization,

- Allyl polymerization, Emulsion polymerization, Amphiphilic polymer, Microgel, Hydrogel ("Molecular design of vinyl-type network polymers with high performance and high functionality")

Publications:

183 papers; 35 reviews and books; 31 patents; 86 presentations at

International Conferences including 22 invited lectures

ir. Leendert Molhoek

DSM Resins, Zwolle, The Netherlands

Title lecture

Amorphous polyamide resins; new versatile binders for fast curing powder coatings

Authors

L.J. Molhoek, J. Dutman

Abstract

Crystalline Polyamides are well known binders for thermoplastic powder

coatings. They combine properties such as toughness, scratch and

chemical resistance. The high melting point and viscosity, however

limits the application of these binders for powder coatings.

DSM has developed a series of amorphous polyamide resins, which can be

crosslinked with all the known hardeners for powder paints. This results

in thermosetting binders for powder paints, which combine the properties

of thermoplastic nylons with the advantages of a thermosetting system.

These thermosetting polyamide binders show some of the previously

mentioned properties such as an excellent ratio of hardness and

flexibility, scratch and chemical resistance together with good

application properties such as gloss, appearance and flow. This paper

will show you some of the chemical structures of these binders, their

physical properties and application results in powder coatings.

Additionally, some of these thermosetting powder paints show an

unexpectedly high curing speed. It appears to be possible to develop

powder paints, which are able to be cured at low temperatures, retaining

most of the properties.On the basis of several chemical and

physical analysis techniques, the cure characteristics of these new

materials at lower temperatures, will be discussed.

Biography

Leendert Molhoek studied organic chemistry at the Technical

University of Delft. He graduated in 1977 (Prof. Beijerman).

He joined DSM Resins in 1979 as a research chemist and holds different

positions in Research and Development. The last 15 years he is involved

in new, innovative projects concerning powder coating resins. Since 2003

he is appointed as a Competence Manager polycondensation chemistry for

the Performance Materials cluster of DSM Corporate.

His field of experience is polycondensation chemistry in general and

coating resins in particular.

Dr. Rolf Nothhelfer-Richter

Forschungsinstitut fuer Pigmente und Lacke e.V., Germany

Title lecture

Investigations of the photoactive activity of pigments and pigmented organic coatings using the reactor method

Authors

R. Nothhelfer-Richter, M. Wanner, W.Ph. Oschsner, C.D. Eisenbach

Abstract

Finishing industry and end-users of construction and wall

paints are calling for additional values like reduced soiling or self

cleaning properties. One approach is to modify coatings by addition of

highly photocatalytically active titanium dioxide (TiO2) which degrades

organic compounds in the presence of UV-light to CO2 and water. Contrary

to inorganic substrates like glass and ceramics [1, 2] where TiO2

activated surfaces are well known, an organic coating has to be

protected against self degradation.

In this context a new testing technique based on a

reactor method has been explored and is being evaluated for the

determination of the photocatalytic activity of pigments and pigmented

organic coatings. The investigations include both the stability of the

coating against self decomposition and the permanence of the

photocatalytical effect.

In this contribution a test chamber method is presented which is based on

the setup used by Searle [3]. The samples to be tested for their

photocatalytic activitiy are placed in a chamber where various climatic

and atmospheric conditions can be applied and controlled including

exposure to model pollutants. During irradiation by UV light, a FTIR

spectrometer records the amount of pollutants and their decomposition

products. This technique does not only allow to follow the

photocatalytic activity of the pigment and pigmented coating regarding

the decomposition of solid, liquid and gaseous model pollutants, but

also to determine the photocatalytic stability of coatings by detecting

the decomposition products of the polymeric binder material. The

quantitative in-situ IR analysis enables the establishing of kinetic

models. The comparative data evaluation is meant to gain scientific

knowledge about adsorption and decomposition processes of

photocatalytically active coatings components and formulations as a

basis for future coatings technologies.

keywords: photocatalytic activity, coatings stability, self-cleaning

- Fujishima, A., Hashimoto, K., Watanabe, T., TiO2 Photocatalysis Fundamentals and Applications, BKC, Inc. Tokyo (1999)

- 4th International Workshop on the Utilization and Commercialization of Photocatalytic Systems, Coatings for Clean Surfaces, and Water and Air Purification Methods, Veranstalter: EJIPAC, Saarbrücken (2004)

- Seale, I.R., Titanium dioxide pigment photocatalysed degradation of PVC and plasticised PVD coatings, Engineering Doctorate Thesis, University of Wales Swansea (2002)

Biography

Dr. Rolf Nothhelfer-Richter

- born 1963

- studied physics at the university of Ulm with main focus polymer physics and mechanical analysis

- phd 1996, topic "Dynamic-mechanical characterization of heterogeneous rubber blends filled with carbon black"

- post doc at the Institute for dynamic Materials Testing (IdM) in Ulm

- since 2001 at the Research Institute for Pigments and Coatings (FPL), now head of physics department

- Main research areas: scratch resistance of coatings, mechanical properties of coatings, surface topology of coatings, photocatalysis

Dr. Jürgen Omeis

BYK-Chemie GmbH, Wesel, Germany

Title lecture

The evolution of structured polymers for coating applications

Author

J. Omeis

Abstract

The major parts of a coating comprise polymeric resins, pigments,

fillers and solvents when applied. Nevertheless, a lot of important

properties are basically driven by surface active effects, such as

colour, shade, deaeration, surface polarity, e.g.

These properties are dramatically influenced by amphiphilic copolymers

specifically interacting with interphases.

The range of suitable molecules is rather broad and varies in terms of

chemical composition, molecular weight and structure. Within this

enormous variety of additive chemistry it is the scope of this review to

demonstrate the emerging synthetic capabilities complying with

well-defined polymeric structures. These structures can vary from simple

binary copolymers to highly sophisticated block and star polymers for

high end applications like colour resists in the optoelectronic

industry.

Biography

CV Dr. Jürgen Omeis

Born 1956, Nürnberg

Education at University of Erlangen and University of Freiburg

- Diploma in Organic Chemistry

- Ph.D. Thesis in Macromol. Chemistry

1986 - 1995 Röhm, Darmstadt Project Manager

- Liquid Crystalline Polymers

- Polymer Blends

- Polymer Additives

1995 - 2004 Fuchs Petrolub, Mannheim

- Head of Global Automotive Development

- Green Chemistry for Lubricoats

- Development and Product Management for Automotive Lubricants

Since 2005 BYK-Chemie, Wesel

- CTO

- Global responsibility for R + D of Paint and Plastic Additives

- More than 20 patents worldwide, several publications and articles.

Dr. Mark Plehiers

Sigma Coatings, Belgium

Title lecture

Synthesis of silyl acrylates for marine coatings

Author

M. Plehiers

Abstract

The constant need for improving the performances of the products

associated to the dramatic growth of environmental regulations force the

resin and paint manufacturers to keep on developing more effective and

less toxic technologies. For example, the now-effective TBT ban of

antifouling coatings induced a considerable pressure on paint

manufacturers to develop and produce tin-free systems. One of the most

attractive tin-free technologies is based on the use of silyl acrylates

as key monomers for self polishing systems.

We will review in this presentation the chemistry developed for the

production of these new functional silanes. We will develop some of the

new concepts developed by SigmaKalon in the field of silane and

polysiloxane chemistry. These offer advantageous alternatives to the

conventional processes known so far and allow the development of new

products for Marine and Protective Coatings.

Biography

Curriculume Vitae Mark Plehiers

- 1995 : PhD in Organic Synthesis, Synthesis of Natural Products, University of Brussels, ULB, Belgium

- 1995-2001: Post Doctoral Research Member at University of Brussels, ULB: In Organic Synthesis of Biocides and of Antifouling Agents

- 2001-2005: Project Leader at SigmaKalon Business Unit Marine and Protective Coatings: Development of New Hydrolysable Monomers and Binders

- 2006-now: Manager of the R&D Resins Department in Manage (SigmaKalon Belgium)

Professor Wenfang Shi

Department of Polymer Science and Technology, University of Science and Technology of China, Hefei, Anhui, P.R. China

Title lecture

Hyperbranched acrylate prepolymers and their potential applications for UV coatings

Author

W. Shi

Abstract

Owing to the unique architecture such as compact 3D structure, high functionality and little chain entanglement, hyperbranched polymers have attracted considerable attention as materials with new application potentials. A series of hyperbranched polymers end-capped with (meth)acrylic groups were synthesized as UV curable prepolymers for coating applications, such as water thinnable and dispersible systems, powder coatings, organic/inorganic hybrid composites. The specific properties that hyperbranched polymers and their UV cured films exhibit have also been described in detail in comparison with linear polymers.

Biography

- graduated with BS from the Department of Modern Chemistry, University of Science and Technology of China (USTC) in July of 1970.

- studied at the Department of Polymer Technology, Royal Institute of Technology (KTH), Stockholm, Sweden as a visiting scholar under Supervisor Professor Bengt Rånby during 1985-1987 and 1992-1994.

- awarded Ph. D. degree in October of 1994 from the Department of Polymer Technology, KTH.

- received the full professor position in 1996 at the Department of Applied Chemistry, USTC.

- Vice President of RadTech China (1995-2006)

- President of RadTech China (2006-)

- Deputy Director of Radiation Technology Institute, USTC (1998-)

Research Interests

- Synthesis and applications of dendrimers/hyperbranched polymers

- Organic nonlinear photorefractive materials

- Radiation curing of organic coatings

- Modification of polymer materials

Willem Jan Soer

Eindhoven University of Technology The Netherlands

Title lecture

Novel Crosslinking Systems for Surfactant-free Latexes Based on Maleic Anhydride Containing Polymers

Authors

Willem Jan Soer, Weihua Ming, Cor E. Koning, Rolf A.T.M. van Benthem

Abstract

We report the successful preparation of surfactant-free, artificial latexes based on maleic anhydride containing polymers. The interactions between two (potential) crosslinkers and the various latexes were studied. It was found that latexes with particle diameters of about 150 nm and a ζ-potential of -70 mV could be obtained for 3 different maleic anhydride containing polymers. When adipic dihydrazide (ADH), a water soluble crosslinker, was added to these latexes, no differences in particle size or ζ -potential were found. When 1,6-diaminohexane (DAH) was added to these latexes, it was found to interact with the polymer particles, indicated by a change in color as well as a large decrease in (absolute) ζ-potential. It was shown that no free DAH was present after addition to the latex, while free, non reacted ADH was shown to be present. Kinetic studies of the crosslinking mechanism revealed that (irreversible) imide formation between anhydride and ADH took place at temperatures of 90 °C and above. 1,6-Diaminohexane (DAH) formed imides at significantly higher curing temperatures, >130 °C. Homogenous films could be formed from these latexes when heated above the respective Tgs of the polymers.

Biography

Willem Jan Soer got his M.Sc. diploma in Chemical Engineering at the University of Twente in 2002, where he graduated in the group of Prof. Dr. Julius Vancso. The topic of his graduation research was the synthesis of organo-metallic amphiphilic block copolymers and the self assembly of these polymers for nanotechnological applications. After that he worked one year in the group of Prof. Dr. Bert Meijer at the Eindhoven University of Technology where he worked on the synthesis of conductive polymers for blue-LED applications. In December 2003 he started his work as a Ph.D.-student with a project on waterborne anti-corrosion coatings in the groups of Prof. Dr. Cor Koning and Prof. Dr. Rolf van Benthem, which he hopes to finish early 2008.

Dr. Milena Spírková

Institute of Macromolecular Chemistry, Prague, Czech Republic

Title lecture

The view from the core onto the surface of self-assembled nanocomposite coatings

Authors

M. Spírková, J. Brus, J. Baldrian, M. Slouf, A. Strachota, J. Kotek

Abstract

The contribution will be aimed the multidisciplinary characterization of hybrid organic-inorganic nanocomposite coatings synthesized by two independent processes: sol-gel process (inorganic in-situ structure build-up) and polyaddition reactions (organic polymeric network formation). Moreover, nanoadditives (colloidal silica, montmorillonite) were used as well in some cases. Solid-state NMR spectroscopy, transmission electron microscopy, small- and wide-angle X-ray scatterings studied "core" properties, while static and dynamic mechanical analyses were used for comprehensive, "bulk" properties of the material. Various microscopy methods (atomic force, light, scanning electron) were utilized for surface characteristics of coatings prepared in the presence/absence of nanoadditives. Three independent methods for surface hardness determination were used as well.

Biography

MSc: 1977, PhD: 1988

Professional Experience

Post-doctoral stay, Université de La Rochelle France, 1 year

Visiting scientist, Université de La Rochelle France, 5 months

Visiting scientist, Chalmers techniska högskola Göteborg Sweden, 2

months

Visiting scientist, Rzeszow University of Technology Poland, 1 month

Research interest

Nanocomposites, coatings and films, sol-gel processing, atomic force

microscopy, preparation and characterization of polymer (mainly

organic-inorganic, epoxy and polyurethane) systems, kinetics and

reaction mechanism of polymer (and low-molecular model substance)

formation, mechanical properties.

Publications

Since 1987: 46 original papers published in international journals

with 244 citations (source: Web of Science). Ca. 90 contributions

presented at international conferences and symposia.

Jeffrey M. Stubbs

DSM NeoResins, Wilmington, USA

Title lecture

The dynamics of morphology development in multi-phase latex particles

Authors

J.M. Stubbs, D.C. Sundberg

Abstract

The use of multi-stage emulsion polymerization to produce particles

containing multiple polymer phases is widespread throughout the

coatings, impact plastics and adhesives industries. Such composite

particles often improve various application properties compared to

related single phase latexes or latex blends. However, the properties

obtained depend in large part on the morphology of the multiphase

particles. This creates incentive to understand the underlying

mechanisms that drive morphology development in these particles as they

are formed in the polymerization reactor. Much research and attention

has been devoted to understanding the thermodynamic factors that

influence morphology control, but in fact the majority of systems are

produced under kinetic control, resulting in non-equilibrium structures.

There are three main kinetic factors involved as the morphology develops

during the second stage polymerization. These are 1) penetration of

polymer radical chains into the particle interior after entry from the

water phase, 2) phase separation of immiscible polymer chains produced

in the different polymerization stages and 3) spatial rearrangement of

phase separated domains.

The factor (or combination of factors) that is dominant will vary from