Speakers COSI 2008

- Ingo Alig, Deutsches, Kunststoff-Institut, Darmstadt, Germany, Scanning acoustic microscopy for investigation of coatings

- Natalya Baklanova,Institute of Solid State Chemistry and Mechanochemistry SB RAS, Russian Federation,Research and development of nanosized interfacial coatings on small diameter carbon and SiC Fibers for composite materials

- José Brokken-Zijp, Eindhoven University of Technology, The Netherlands, Polymer composites with (semi)-conductive nano-fillers

- Fabiola Brusciotti, Vrije Universiteit Brussel (VUB), Brussels, Belgium, Characterization of hybrid organic / silicon based coatings deposited by wet and plasma deposition methods

- Pascal Buskens, DSM Research, Geleen, The Netherlands,State of the art single layer anti-reflective coatings

- Tessa ten Cate, TNO Science and Industry, Eindhoven, The Netherlands,, Tailored surface properties using polymer brush coatings

- Yoshiki Chujo,Kyoto University, Japan,Organic-inorganic polymer nano-hybrid materials

- Guillermo J. Cruz, Departamento de Física, Instituto Nacional de Investigaciones Nucleares, Apdo. México,Metallic layers added by plasma on polyethylene

- Joost van Dijk, AkzoNobel, The Netherlands Pushing polyurethane crosslinking beyond its speed limit

- Alexander Fedorov, Department of Applied Physics, Netherlands Institute for Metals, University of Groningen, The Netherlands, Degradation of adhesion in deformed polymer-metal interfaces studied by laser induced delamination technique

- Adolphe Foyet, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands, Permeability of water and corrosion performance of epoxy-coated aerospace alloy evaluated by electrochemical impedance spectroscopy

- Nathalie De Geyter,Ghent University – Faculty of Engineering – Department of Applied Physics – Rsearch Unit Plasma Technology (RUPT) – Gent – Belgium,Deposition of hydrophobic coatings on polymer films using a dielectric barrier discharge

- Bernd Göbelt, Byk-Chemie GmbH, Wesel, Germany, Flat panel display: tuning the developing properties of the color resist

- Horst Hintze Bruening, BASF Coatings AG, Muenster, Germany, Layered particle based polymer composites for coatings: Part II – Coatings morphology and mechanical properties

- Gerhard Jonschker, Merck KGaA, Germany, F Darmstadt, Germany, New monodispersed core/shell nanoparticles for improving scratch resistance of coatings

- Eun-Hee Kim, School of Nano & Advanced Materials Engineering, Changwon National University,Changwon, Korea, Polyhedral oligomeric silsesquioxane reinforced polyurethane acrylate

- Ralf Knischka,

Ciba Specialty Chemicals Inc. Coatings Effects Segment, Basel, Switserland,

Novel approaches in NIR curing technology - Ria Kress, BASF Coatings AG, Munster, Germany, Innovative production process for pigmented powder coatings

- Baoshun Liu, Key Laboratory of Silicate Materials Science and Engineering, Ministry of Education, China, Wuhan University of Technology, Wuhan City, Hubei Province, P.R. China, Efficent degradation of aqueous methyl orange over TiO2 and CdS electrodes using photoelectrocatalysis under UV and visible light irradiation

- Jonathan W. Martin, National Institute of Standards and Technology (NIST) Gaithersburg, MD 20889, USA, Linking field and laboratory exposure and predicting long-term performance of an epoxy coatings

- Ralf Posner, University of Paderborn, Faculty of Science, Department of Chemistry - Chemical Engineering, Paderborn, Germany,Structure and stability of polymer/oxide/metal interfaces: Bridging the gap between interface analysis and advanced surface technologies

- Patrice Roose, Cytec Surface Specialties, Drogenbos, Belgium,Radiation curing: An attractive technology for metal coating

- Masaaki Saika, SR Institute, Kansai Paint Co. LTD. Hiratsuka-shi, Kanagawa, Japan, CO2 Emission reducible coatings based on modified corn-starch

- Masamitsu Shirai, Osaka Prefecture Univeristy, Department of Applied Chemsitry, Osaka, Japan, i-Line sensitive photoacid generators for UV curing

- Per Aggerholm Sørenson, Department of Chemical Engineering, Technical University of Denmark, Lyngby, Denmark, Influence of substrate characteristics on cathodic delamination of anticorrosive coatings

- Ananda kumar Srinivasan, Department of Chemistry, Anna University, Chennai – India, Development and characterization of phosphorus containing siliconized epoxy resin coatings

- Per-Erik Sundell, SSAB Tunnplat AB, Sweden, UV-cured coil coatings - product performance and outdoor durability

- Stacy M. Trey, Dept. of Fiber and Polymer Technology, The Royal Institute of Technology, Stockholm, Sweden, Effect of residual stress build-up and cure shrinkage in UV cured acrylate resins on adhesion to SMC substrates

- Anne-Lise Troutier, University Blaise Pascal, Clermont-Ferrand, France, Layered particle based polymer composites for coatings: Part I – Evaluation of inorganic layered particles

- Björn Weber, University Paderborn, Germany, Creating new materials with melamine resins

- Dean C. Webster, Department of Coatings and Polymeric Materials, North Dakota State University, Fargo, ND 58105 USA, Hybrid sol-gel coatings from glycidyl carbamate functional resins

- Mariëlle Wouters, TNO Science & Industry, Eindhoven, The Netherlands, Preparation and properties of a novel remendable coating concept

- Mikhail L. Zheludkevich, DECV/CICECO, Universidade de Aveiro, Aveiro, Portugal, LDH-based nanocontainers as anticorrosive pigments for protective coatings

- Thomas Zwieg, Larsen Strings A/S, Sonderborg, Denmark, Optimisation of tone quality or timbre of musical strings for bowed instruments

dr. Ingo Alig

Deutsches Kunststoff-Institut, Darmstadt, Germany

Title lecture

Scanning acoustic microscopy for investigation of coatings

Authors

I. Alig, S. Tadjbach, P. Kruger, D. Lellinger, H. Oehler

Abstract

To develop coatings which guarantee optimal protection against environmental influences (weathering, chemicals etc.), it is necessary to detect and to differentiate the related defects in coatings already during their development. Various accelerated weathering tests and other methods (e.g. salt spray test) have been developed to save costs and to speed up the material development. Despite of the progress in high throughput experimentation, visual inspection is still the dominant screening method for coatings. However, visual inspection has several disadvantages: (i) the defects must be visible by naked eyes, (ii) it is a highly subjective method, and (iii) it is limited to defects, which are visible at the coating surface. The latter is an important limit for early detection of defects. The detection of delaminations or air bubbles in pigmented coatings is only possible if defects are visible at the surface. Therefore, methods which allow automatic detection of defects (e.g. in early stages of weathering tests) are highly desired. Such a method should provide the potential to locate the defects also inside the coating and to differentiate between various types of defects.

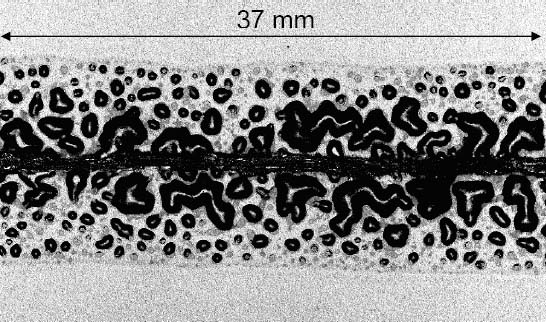

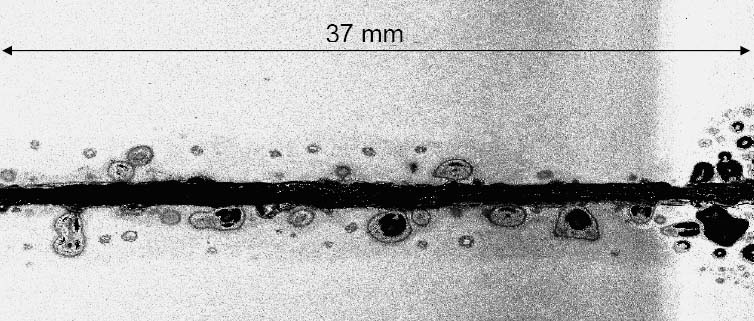

Scanning acoustic microscopy (SAM) is well known as a non-destructive imaging method for quality and process control and for research applications, especially in microelectronics. However, the applications to polymer materials are still rare. The principle of a SAM is similar to that of a scanning electron microscope. The individual points of the image are successively scanned and composed to the final picture. In SAM, high frequent acoustic pulses are excited and focused by an acoustic lens into the material. The area of interest is located in the focal plane. The reflected and/or transmitted acoustic signals are detected for each position and the images are processed from the digitized signals (selected amplitude and/or phase of the echo train). In this study SAM has been tested for detection of the early phase of delamination, air bubble distribution (›10 µm), agglomerates (e.g. pigments, fillers), speckles and surface defects (scratches, orange skin or pores). Fig. 1 shows delaminations spread out from a scratch after salt spray test.

|

|

Figure1: SAM images of delaminations spread out from a scratch after salt spray test for a single (left) and double layer (right) polyurethane coating.

SAM can be applied for clear coats as well as for pigmented single and multi layer coatings without specific sample preparation. The possibility of a quantitative analysis of weathering induced defects is one of the advantages of the method. The development and implementation of specific software for coating applications (e.g. ”surface scan” for topography imaging) is in progress.

Biography

Ingo Alig (Ph.D., D.Sc.)

- Head of Department of Physics at Deutsches Kunststoff-Institut in Darmstadt, Germany

- lecturer at Technical University Darmstadt

- EDUCATION

- Ph.D. 1983 in Physics, Technical University Merseburg

- Habilitation (D.Sc.) 1988 in Experimental Physics

- POSITIONS

- 1978-1991 Senior scientist at Department of Physics at Technical University Merseburg

- 1989-91 visiting scientist at Research Center of Crete/Greece, McMasters University Hamilton/Canada, Max Planck Institute for Polymer Science

- 1991-1993 senior scientist at the Institute for Physical Chemistry of University Köln

- 1993-now Head of department of Physics at the Deutsche Kunststoff-Institut and lecturer at Technical University Darmstadt

dr. Natalya Baklanova

Institute of Solid State Chemistry and Mechanochemistry SB RAS, Novosibirsk 630128 Russian Federation

Title lecture

Research and development of nanosized interfacial coatings on small diameter carbon and SiC fibers for composite materials

Authors

Natalya Baklanova, Anatoly Titov, Boris Zaitsev

Abstract

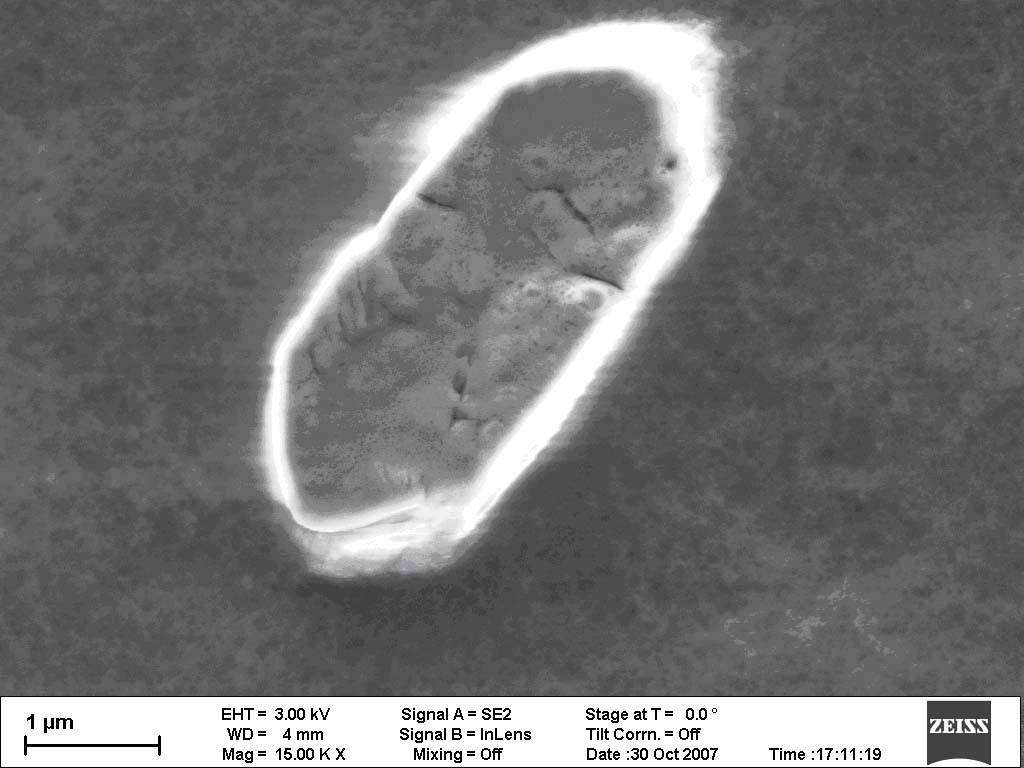

It is widely accepted that the mechanical properties, the environmental stability and the failure mechanisms of fiber-reinforced matrix composites are strongly influenced by the interfacial fiber/matrix zone. Matrix composites reinforced by carbon or SiC-based fibers achieve high toughness and damage tolerance through the disposal of fiber coating which can deflect cracks and promote debonding at the fiber/matrix region.

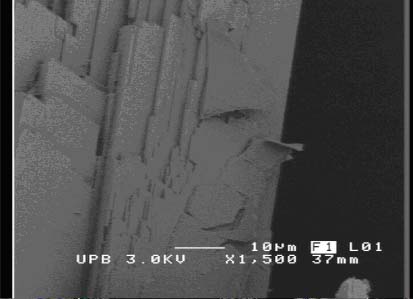

The special approaches for fabrication of thin (not more than 500 nm), uniform and oxidation resistance interfacial coatings on small diameter carbon and SiC filaments will be considered. These approaches include reactive chemical vapor deposition, sol-gel and deposition from organosilicon precursors. The refractory oxide and carbide coatings were obtained using these approaches. The evaluation of nanoscale properties of the interfacial coatings with different techniques such as high resolution scanning electron microscopy, energy dispersive analysis, X-Ray photoelectron spectroscopy, atomic force microscopy, and micro Raman spectroscopy will be considered. The morphology, composition, topography, roughness, adhesive forces, tensile strength properties of coated carbon and SiC fibers will be discussed in details. A special attention will be paid to quantitative characterization of the nanosized interfacial coatings on fibers. The peculiarities of the behavior of zirconia-based interphase with accurate phase control will be discussed in details. Criteria for further optimization of interphase will be formulated.

Biography

Baklanova Natalya is Senior Researcher of Institute of Solid State Chemistry and Mechanochemistry, Siberian Branch of Russian Academy of Sciences, Novosibirsk

PhD in Chemistry, Leader of Advanced Ceramic Materials Group.

Dr. Baklanova’s current research focuses on the high-temperature composite materials with heavy emphasis on the R&D of the interfacial coatings on reinforced fibers. Research activities cover design interphase in composites, mechanisms of formation and microstructure of nanosized coatings on fibers, mechanism of transformation of preceramic polymers into ceramics, characterization of thin films. She has published over 100 articles in International and Russian journals. She was Leader or Key Researcher of several Russian and International Projects.

dr. José Brokken-Zijp

Laboratory of Materials and Interface Chemistry, Dept. of Chemical Engineering and Chemistry, Eindhoven University of Technology, The Netherlands

Title lecture

Polymer composites with (semi)-conductive nano-fillers

Authors

José Brokken-Zijp, Ming Yuan, Laura Huijbregts, Wilfred Kleinjan, Gijsbertus de With

Abstract

The use of nano-fillers in polymer matrices is an important research subject at this moment, because it has been shown that by lowering the size of the filler to nano level, major improvements in the material properties of a polymer matrix can be realized. However, only a few polymer nano-composites are commercialized yet and these products can be, generally, used only in specific applications. Important reasons for the limited commercialization of these products are the limited amount of attractive nano-fillers commercially available, the lack of knowledge on the influence of processing conditions and chosen starting formulations on the morphology and the material properties of the polymer nano-composites produced. This lack of knowledge is especially large when a thermoset polymer is used in the form of thin coatings.

During the last years several nano-filler thermoset polymer coating combinations has been studied in depth in our group. The main focus has been on crosslinked acrylate and epoxy coatings containing different types of (semi)-conductive nano-fillers. In this presentation an overview will be given on our results of the last years. The focus will be on the relation between the initial formulation and processing conditions used, the morphology and the final conductivity properties of these coatings. Explanations will be presented why crosslinked thermoset nano-composites, in general, are conductive only when specific filler matrix combinations are used and why these composites have to be prepared within a small processing window.

dr. Horst Hintze-Bruening

BASF Coatings AG, Muenster, Germany

Title lecture

Layered particle based polymer composites for coatings: Part II – Coatings morphology and mechanical properties

Authors

Horst Hintze-Bruening, Anne-Lise Troutier, Fabrice Leroux

Abstract

The impact resistance of automotive coatings can be enhanced using a polymer

composite comprising layered inorganic nanoparticles as a coating layer.

Limiting the extend of coatings delamination upon stone chipping is becoming crucial within modern automotive coatings bearing reduced numbers of layers or layer thicknesses. Energy dissipation has to be translated into reinforcement and toughening of the material, limitation of crack growth and direction of failure mode to sacrificing loci.

Highly filled composites applied as primer layers normally can not address all those energy dissipation modes due to their morphology on the µ-scale.

We show that specific interactions of layered inorganic nanoparticles with the polymer matrix components improve the impact resistance of coating systems comprising such nanocomposites. Energy dissipating structures are presented like dispersed intercalated / exfoliated platelets, ”springs” comprising sandwiched inorganic stacks and soft polymer layers as well as morphologies on different length scales resulting from particle controlled spinodal polymer demixing.

We anticipate our findings will trigger further developments of composites using layered nanoparticles and application affected coating resins.

Biography

Dr. Horst Hintze-Bruening - Short CV

- 78-84 studies in chemistry

- 84-87 doctoral thesis ”Mechanistic Studies on Thermal and Catalytic Hydrogen Transfer Reactions”

- 87-present BASF Coatings AG, Muenster (current position: head of research lab ”colloidal systems”)

dr. Fabiola Brusciotti

Vrije Universiteit Brussel (VUB), Department of Metallurgy, Electrochemistry and Materials Science (META), Brussels, Belgium

Title lecture

Characterization of hybrid organic/silicon based coatings deposited by wet and plasma deposition methods

Authors

F. Brusciotti, A. Batan, I. De Graeve, M. Wenkin, R. Reniers, J.J. Pireaux, J. Vereecken, H. Terryn

Abstract

Hybrid organic/silicon-based coatings were deposited on Al 99.99% substrates using three different techniques: wet deposition, atmospheric plasma and vacuum plasma. Spectroscopic Ellipsometry, infrared (IRSE) and visual (VISSE), Fourier-transform Infrared Spectroscopy (FT-IR), X-Ray Photoelectron Spectroscopy (XPS) and Field Emission Auger Electron Spectroscopy (FE-AES) were used to investigate film structure, chemical composition and surface morphology. Preliminary analysis of the coating solutions was performed with Nuclear Magnetic Resonance (NMR) and Dynamic Light Scattering (DLS).

Dip coating was used to deposit Bis-1,2-(TriethoxySilyl)Ethane (BTSE) layers with inclusion of CeO2 nanoparticles for added functional properties. SEM micrographs and AES depth profiles showed the ceria distribution and agglomeration in the layers. Plasma-polymerized films from BTSE were deposited on aluminium by atmospheric plasma. Both XPS and infrared measurements revealed the presence of silicon under Si-O state.

Inductively coupled radio frequency glow discharge plasma was used for the deposition of plasma-polymerized film from hexamethyldisiloxane (HMDSO). The deposited films consist of groups such as Si-O-Si, Si-CH3, and CH3. They can be considered as polymer-like coatings, comparable to the silane layers obtained by the deposition methods described above.

Biography Dr. Fabiola Bruscotti

Vrije Universiteit Brussel (VUB) (March 2007-Present) - Dept. Metallurgy, Electrochemistry and Materials Science (META)

- Post-doctoral researcher – Research on functional properties by mixed nano organic/metal oxide systems (FOMOS)

Columbia University in the City of New York (January 2002 – Present)

-

Course Manager for Columbia Video Network, the graduate distance learning program of Columbia University's School of Engineering & Applied Science.

Responsible for the courses of: Corrosion of Metals, Industrial Electrochemistry, Aquatic Chemistry, and Processing Metals and Semiconductors

EDUCATION

Columbia University in the City of New York

- Ph.D. in Earth and Environmental Engineering, June 2006

Thesis: Removal of Arsenic from Water: An Electrochemical Investigation - Other projects:

- Corrosion tests for assessing the properties of Engelhard soap products on stainless steel and studying the anti-corrosion effect of some additives.

- Corrosion tests of a specific Kraft beverage product on stainless steel.

- Recycling of pure Cd from photovoltaic cells.

- Master of Science in Earth and Environmental Engineering, February 2001

Thesis: Glass Recycling: Separation of Colors through flotation

State University of New York at Stony Brook

- Bachelor of Engineering, summa cum laude, in Materials Science and Engineering, May 1999

University ”La Sapienza” of Rome (Italy)

- Student in Earth and Environmental Engineering, 1994-1996

dr. Pascal Buskens

DSM Research, Geleen, The Netherlands

Title lecture

Innovation at DSM: State of the Art Single Layer Anti-Reflective Coatings

Authors

Pascal Buskens, Roberto Habets, Harm Langermans, Patrick Vrijaldenhoven, Guido Meijers, Ellis Derikx, Ron de Rijk, Nanning Arfsten, and Jens Thies*

Abstract

Optical reflection is a fundamental phenomenon that occurs when light propagates across a boundary between two media with different refractive indices. In principal, there are two approaches to lower the reflection of a substrate: the application of an interference-type multiple layer coating system or the use of one single porous graded index coating. Although the application of a single-layer anti-reflective (AR) coating is the most efficient of both approaches, it is not yet commonly used in industry. The reason for this paradox is the high level of porosity required to obtain good AR properties with this technology. This is usually accompanied by a high surface roughness which causes poor abrasion resistance, a high degree of optical fouling and problems with cleaning.

DSM started a research program on single layer AR coatings in 2002 with the development of AR coatings for the display market. In the course of this program a UV cured organic/inorganic hybrid coating was developed (OptoclearTM). This technology is based on inorganic nanoparticles modified with polymerisable acrylate groups. A multi-functional acrylate is used for network formation. The necessary level of porosity in these coatings is achieved by the packing of the modified nanoparticles. Depending on the size and morphology of the particles, levels of porosity between 25% and 50% are achieved. The resulting coating shows a low rest reflection (£ 1.5%) and a good abrasion resistance.

In 2005, DSM decided to extend the research program with a project on AR coatings for glass substrates. This led to the development of ®claryl, DSM’s picture glass, which was launched in October 2007. This AR glass contains a state of the art single-layer anti-reflective coating and is produced in a straightforward dip-coating process. By controlling the balance of surface roughness and internal porosity DSM managed to overcome the typical drawbacks mentioned above providing a mechanically robust and easy-to-clean anti-reflective glass with a transmission of 98% or higher and a low level of rest reflection (£ 1.2%).

Further optimization of the balance of surface roughness and internal porosity provides the coating with an excellent outdoor stability. This makes the glass suitable for outdoor applications like solar cells and greenhouses. Studies towards further improvement of the outdoor stability of our coating are currently ongoing in our laboratories.

dr. Tessa ten Cate

TNO Science and Industry, Eindhoven, The Netherlands

Title lecture

Tailored surface properties using polymer brush coatings

Authors

Tessa ten Cate, Susan Reinders, Daniel Turkenburg, Kjeld van Bommel

Abstract

Brush coatings are a relatively new class of coatings, consisting of a monolayer of polymer chains covalently attached to a surface. Being less than a hundred nanometers thick, they allow the creation of functional surfaces without altering the inherent properties or appearance of a product. We have developed a versatile technology to apply polymer brush coatings to a broad range of substrates, including polymers and metals. The use of a functional primer ensures a very high grafting density and good chemical stability. This way, we are able to create for instance a hydrophilic brush coating, which prevents the adhesion of bacteria to a surface and could be used as a hygienic coating for medical devices. Alternatively, the brush coating technology can be used to produce blood compatible surfaces or water-repellent surfaces.

Professor dr. Yoshiki Chujo

Kyoto University, Katsura, Department of Polymer Chemistry, Graduate School of Engineering, Nishikyo-ku, Kyoto Japan

Title lecture

Organic-inorganic polymer nano-hybrid materials

Abstract

The synthesis of poly(vinyl chloride) / polyhedral oligomeric silsesquioxane (POSS) polymer hybrids was performed utilizing CH/π interaction. Poly(vinyl chloride) (PVC) as an organic component was dissolved in THF with octaphenethylsilsesquioxane (Phenethyl-POSS) or octacyclohexylsilsesquioxane (Cyclohexyl-POSS) as an inorganic component. The resulting mixture was placed at 40 °C for 2 weeks. The obtained polymer hybrid was dried in vacuo at 60 °C for 2 days. The transparent polymer hybrids were obtained when Phenethyl-POSS was employed as an inorganic component. In contrast, polymer hybrid became turbid when Cyclohexyl-POSS was used. These results suggest that the CH/π interaction was found to act as an important role for the dispersion of Phenethyl-POSS in the PVC matrix.

dr. Guillermo J. Cruz

Departamento de Física, Instituto Nacional de Investigaciones Nucleares, Apdo. México.

Title lecture

Metallic layers added by plasma on polyethylene

Authors

Guillermo J. Cruz, Ma. Guadalupe Olayo, Regulo Lopez, Everardo Granda, Munoz Arturo, Valencia Raul

Abstract

Materials prepared with polymers and metals have been studied for long time in order to enhance their properties. This work presents a study on the addition of layers composed by different metals on thin films of Polyethylene (PE). The process combines Stainless Steel, Titanium and Aluminum, to form agglomerates that can be deposited on the surface of PE. This process requires a great interchange of energy; however, many experimental conditions were studied in order to preserve the structural integrity of the polymers.

PE films with thickness of 1 mm were used in a vacuum reactor were the metallic layers were implanted by plasma at 4 Pa, 400-600 V dc, 0.5-3 A, and temperatures between 300 °C and 600 °C. The results indicate that the polymers reacted in a first step with the carrier gases, Oxygen and Nitrogen, that eroded the surface. After that, the metallic particles were adhered forming thin layers with a growing rate in the 1-2 nm/min interval. The metallic layers changed the hardness of PE, which increased more than 20 times.

dr. Joost van Dijk

AkzoNobel, The Netherlands

Title lecture

Pushing Polyurethane Crosslinking beyond its Speed Limit

Author

Joost van Dijk

Abstract

High performance coatings usually are based on two component crosslinking binder compositions. Especially in the case of the more conventional application techniques such as brushing and roll application, cross linking speeds are limited by the requirements set for the pot life of the mixed components. A pot-life of 8 to 10 hours is the minimum for the application of 2K technology in Decorative Coatings.

In this study, the focus was on poly-urethane coatings based on isocyanate cross linking. By making smart use of chemistry, application methods and ambient circumstances, it is possible to break through the existing pot-life-cure barriers. The result is a series of products that still use the same conventional application techniques but has spectacular improvements of curing and through hardening even at low temperatures. This new technology was applied in concrete protection coatings. Also commercially those coatings have been a great success in the market since their introduction, end 2005.

dr. Alexander Fedorov

Department of Applied Physics, Netherlands Institute for Metals, University of Groningen, The Netherlands

Title lecture

Degradation of adhesion in deformed polymer-metal interfaces studied by laser induced delamination technique

Authors

Alexander Fedorov, Willem-Pier Vellinga, Jeff De Hosson

Abstract

Adhesion properties of polymer coatings on metals subjected to deformations during

manufacturing process are of great interest to modern industrial applications, including automotive industry and packaging of food. In this work, the effect of plastic deformations of metal substrate on the adhesion properties of polymer-metal interface is investigated. Steel samples laminated with polyethylene terephthalate (PET) were subjected to uniaxial tensile deformations which in some cases were followed by a thermal treatment. The experimental method used in this study is a laser induced delamination technique [1].

Particular interest was focused on the effect on adhesion of in-plane stress fields introduced in the coating by the deformation. Under certain conditions, such stresses can lead to a spontaneous delamination. In the experiments performed, both the practical work of adhesion and the in-plane stresses present in the coating were measured.

The measurements have demonstrated degradation of adhesion of the metal-polymer interface as the deformation of the substrate increases. In line with expectations, the in-plane stresses introduced in the coating increased with the deformation. After annealing of the samples partial restoration of the adhesion was observed.

1. A. Fedorov, J.T.M. De Hosson, J. Appl. Physics 97, 123510 (2005)

dr. Adolphe Foyet

Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands

Title lecture

Permeability of water and corrosion performance of epoxy-coated aerospace alloy evaluated by electrochemical impedance spectroscopy

Authors

A. Foyet, T-H. Wu, L. van der Ven, A. Kodentsov, G. de With, R. van Benthem

Abstract

Aluminum alloy 2024 is widely used in aerospace industry because of its high weight to strength ratio. But it easily undergoes pitting corrosion in the presence of water and diluted oxygen. This material is usually protected with a film of organic coating in order to reduce the corrosion rate. Two components epoxy-coatings are very attractive in corrosion protection because of the strong adhesion bonds with the substrate. Actually, their barrier properties are limited since they are permeable to water and oxygen to some extent. Water permeation properties of organic coatings are a reflection of their structure and composition. For example, if one of the coating components (epoxy resin or amine hardener) is in excess, a full cross-linked network will not be reached. This will lower the properties of the resulting material. The aim of this work is to improve the long-term stability of the epoxy coating/aluminum alloy interphase. First of all, it would be interesting to understand the relation between the formulation (mixing ratio) and the permeation properties of epoxy coating in order to choose the optimal composition. Water and oxygen permeation of organic coatings are closely related to corrosion at the coating / substrate interphase.

Nathalie De Geyter

Ghent University – Faculty of Engineering – Department of Applied Physics – Research Unit Plasma Technology (RUPT) – Gent – Belgium

Title lecture

Deposition of hydrophobic coatings on polymer films using a dielectric barrier discharge

Authors

Nathalie De Geyter, Rino Morent and Christophe Leys

Abstract

Low temperature plasma treatment by means of dielectric barrier discharges (DBDs) constitutes an emerging technology for polymer film treatment. DBD systems have been developed and optimised for the sterilization and activation of surfaces before printing, gluing or top-coating. However, in recent years, laboratory and semi-industrial scale experiments have demonstrated the interesting capabilities of this technology for in-situ coating deposition. This can be done by injection of gaseous or vaporized chemical precursors in the plasma discharge. Unlike low pressure plasma deposition, which generally targets metal oxide or nitride coatings, a DBD is most suited for deposition of organic and hybrid organic-inorganic coatings.

Until recently, the variety of coating precursors used in DBD deposition was limited to gaseous chemicals and liquid precursors with a high vapour pressure and/or high thermal stability which considerably limited the coating capabilities. Furthermore, deposition rates are in most cases too low to meet the requirements for in-line production. The use of nano-sized aerosols enables to overcome the latter limitations. It allows making use of the full variety of chemical compounds available today and to drastically increase the deposition rates. The presented work describes the deposition of hydrophobic coatings by injection of a siloxane-based precursor (hexamethyldisiloxane) to the plasma as aerosol particles formed by atomisation

Biography

Nathalie De Geyter obtained a materials engineering degree at Ghent University, Belgium in 2004. Since September 2004 until now, she is working as a member of the academic assistant staff at the department of Applied Physics, Ghent University, Belgium. She is currently pursuing a Ph.D. degree in physical engineering on plasma technology for surface modification.

dr. Bernd Göbelt

Byk-Chemie GmbH, Wesel, Germany

Title lecture

Flat panel display: tuning the developing properties of the color resist

Author

Bernd Göbelt

Abstract

Color filter coatings are applied in a multi-step process. In each step of the process the requirements to the coating changes. The color resist contains organic solvents, in which it has to have an excellent solubility when it is applied on the glass panel. But it also must have a good water-solubility as in the developing step later on in the application process when a part of the dried, non-cured coating is removed with an aqueous solution in order to create the pixel pattern of the display.

To achieve these different solubility properties of the color resist the selection of the wetting and dispersing additive plays an important role. The presentation will discuss different strategies how to influence the solubility properties of the color resist with wetting and dispersing additives.

Biography

Bernd Göbelt, born in Stuttgart, Germany, studied chemistry at the universities in Stuttgart and Kaiserslautern. In 1999 he received his Ph.D. degree for his work in the area of organic and polymer chemistry from the university of Heidelberg. In 1999/2000 he undertook postdoctoral research at the Carnegie Mellon University with Prof. K. Matyjaszewski on atom transfer radical polymerisation. In 2001 he joined Byk-Chemie. He works mainly on the development of wetting and dispersing additives and controlled radical polymerization technologies.

Ralf Posner

representing

Professor Guido Grundmeier

University of Paderborn, Faculty of Science, Department of Chemistry - Chemical Engineering, Paderborn, Germany

Title lecture

Structure and stability of polymer/oxide/metal interfaces Bridging the gap between interface analysis and advanced surface technologies

Author

G. Grundmeier

Abstract

The design of long-term stable and corrosion resistant polymer/oxide/metal interfaces can be based on the interfacial analysis of the chemical, electrochemical and microscopic structure. Mainly in-situ analytical studies are of interest to reveal the mechanisms of adhesion and de-adhesion under ambient conditions. Highlighted techniques will be FTIR- and Raman spectroelectrochemistry, Chemical Force Microscopy and the Scanning Kelvin Probe technique.

These methods can be combined with applied computational chemistry which helps to analyze interfacial chemical bonds and adsorption processes mainly on single crystalline oxide surfaces. Systems under investigation are organosilanes and organophosphonic acids as molecular adhesion promoters on zinc and aluminium oxides.

The thereby generated knowledge serves as basis for the design of highly corrosion resistant organic coatings and adhesives on zinc, aluminum or steel substrates.

The presentation gives an overview about the corresponding recent research and tries to bridge the gap between the theoretical aspects of interface chemistry and the technically relevant surface chemistry.

References

- Valtiner, M., Borodin, S., Grundmeier, G.: Preparation and characterisation of hydroxide stabilised ZnO(0001)-Zn-OH surfaces. In: PHYSICAL CHEMISTRY CHEMICAL PHYSICS, 9, 19, 2406-2412 (2007).

- Klimow G., Fink N., Grundmeier G.: Electrochemical studies of the inhibition of the cathodic delamination of organically coated galvanised steel by thin conversion films. In: ELECTROCHIMICA ACTA (2007), 53 (2007) 1290–1299

- Vlasak R., Klueppel I., Grundmeier G.: Combined EIS and FTIR–ATR study of water uptake and diffusion in polymer films on semiconducting electrodes. ELECTROCHIMICA ACTA 52 (28): 8075-8080 (2007)

- K. Wapner, M. Stratmann, G. Grundmeier Structure and stability of adhesion promoting aminopropylphosphonate layers at polymer/aluminium oxide interfaces; International Journal of Adhesion & Adhesives 28 (2008) 59–70

Biography Ralf Posner

2001-2006: Study of Chemistry at Düsseldorf University, Germany since 2006: Doctoral student within the Christian-Doppler-Laboratory for Polymer/Metal-Interfaces at the Max-Planck-Institut für Eisenforschung, Düsseldorf, Germany under the supervision of Prof. Grundmeier. Research topics: Investigation of ion and water transport at polymer/oxide/metal interfaces, corrosive degradation of polymer/substrate interface designs, functional layer for an improved polymer/substrate interface stability.

dr. Gerhard Jonschker

Merck KGaA, Germany, Darmstadt, Germany

Title lecture

New monodispersed core/shell nanoparticles for improving scratch resistance of coatings

Authors

J. Pahnke, J. Schütz-Widoniak, R. Friedrich, G. Jonschker

Abstract

Today, coatings manufacturers have to face customer expectations, which are not in every case realizable with conventional polymer chemistry. Approaches to improve mechanical and other properties with inorganic nanoparticles were found and started a hype beginning in the 1990’s which was followed by disillusionment and unmet expectations due to incompatibility, expensive dispersion techniques or simply a visible haze of the still agglomerated ”nanoparticles”.

In only a few coating systems today nanoparticles are used. The reason for this is mainly the ”inorganic” behaviour which causes the still omnipresent compatibility and/or haze problems.

A new approach which overcomes these drawbacks are core/shell particles, consisting of an inorganic core and a shell of grafted organic polymers.

These particles can be synthesized as bulk or almost transparent dispersions in common solvents and can be easily formulated with a variety of resins to yield haze-free glossy coatings, even on deep black surfaces. Variation of polymer chemistry provides every means to adapt the nanoparticles to the needs of the customer.

Scratch and abrasion tests show that the scratch resistance of OEM series clearcoats can be significantly increased and that repair coatings can achieve the scratch resistance of OEM coatings.

Biography

Dr. Gerhard Jonschker, born 1966 Chemist, PhD in materials science Department head at the ”Institute for New Materials GmbH” in Saarbrücken, Germany. Head of the application center - 1998 Co-founder of the stock market listed startup company (Nanogate AG). Director of the business unit ”Surface Technology” - 2004 Business Development Manager at Merck KGaA Darmstadt - present

Eun-Hee Kim

School of Nano & Advanced Materials Engineering, Changwon National University,Changwon, Korea

Title lecture

Polyhedral oligomeric silsesquioxane reinforced polyurethane acrylate

Authors

Eun-Hee Kim, Sang-Won Myoung, Yeon-Gil Jung, Ungyu Paik

Abstract

Polyhedral oligomeric silsesquioxane (POSS) have been emerged as a new chemical technology for reinforced organic-inorganic hybrids. Polymer incorporated POSS has advantages of the simplicity of processing and the excellent comprehensive properties of hybrid materials. POSS added to the conventional polyurethane acrylate (PUA) provides the increased elasticity, glass transition temperature (Tg), thermal stability and dimensional stability. Therefore, in this study, the effect of additional amounts of POSS on properties of PUA films has been investigated to determine the optimum additional amounts and to obtain the best properties. Properties of PUA films contained POSS were measured by Fourier transform infrared spectroscopy (FT-IR), dynamic mechanical thermal analysis (DMTA), thermogravimetric analysis (TGA) and contact angle measurement. With increasing POSS contents, modulus and thermal stability of PUA films are increased owing to the nanoscale reinforcement effect of POSS particles on PUA films and the surface free energies of PUA films are decreased. However, when the additional amounts of POSS into PUA films are higher, the properties of PUA films are deteriorated by aggregation of POSS particles.

Keywords: Nano-sized polyhedral oligomeric silsesquioxane (POSS); Polyurethane acrylate (PUA); Elasticity; Organic-inorganic hybrids; Thermal stability; Surface free energy.

dr. Ralf Knischka

Ciba Specialty Chemicals Inc. Coatings Effects Segment, Basel, Switserland

Title lecture

Novel approaches in NIR curing technology

Authors

R. Knischka, P. Nesvadba, K. Powell, T. Jung, U. Lehmann, U. St, K. Studer, J. Benkhoff

Abstract

Near infrared (NIR) curing technology is used more and more in coating processes where high belt speeds are needed reducing the curing time from minutes down to seconds. In times of increasing concern for energy consumption it is vital to optimize the uptake of energy by the coating system caused by differences in pigmentation. As standard clear coats typically do absorb NIR radiation only to a small extent the heat uptake proceeds mainly indirect via thermal conduction from the substrate, e.g. steel and by convection. In pigmented systems the NIR absorption is strongly dependent on the choice of inorganic and organic pigments. Again, pale shades absorb only little amounts of NIR radiation. For further penetration of NIR curing technology into industrial reality efficient, colorless and transparent NIR absorbers would be highly desirable. In this paper for the first time data will be presented showing the use of an efficient NIR-Absorber in different pigmented as well as transparent coating formulations.

Biography

Job:

- 11/2004- present: Ciba Holding Inc.; Application Staff Specialist TC-BLC Powder Coatings & New Technologies

- 09/2001-10/2004: Ciba Specialty Chemicals Inc., Basel; Lab Leader R&D Polymer Specialties

- Ciba R&D Award 2004 „Novel Polymer Specialties by Controlled Free Radical Polymerization”

- FATIPEC Price of Excellence 2004 ”Controlled Polymer Pigment Dispersants ”

- 03/2000-09/2001: mnemoScience GmbH, Aachen, Germany, site head.

Study:

- 02/1997-02/2000

PhD work at the Institute of Macromolecular Chemistry and Freiburg Materials Research Center of the Albert-Ludwigs-Universität in Freiburg i. Br. in the group of Prof. Dr. R. Mülhaupt (direct supervisor: PD Dr. H. Frey). - Scholarship holder of the Graduiertenkolleg „structure formation in macromolecular systems”,

- 02/1997-01/2000

Degree: PhD, grade: magna cum laude - 1 year at the CNRS, Strasbourg, France

- Further subjects: pharmaceutical technology, polymer physics

- 10/1991-01/1997

Study of chemistry at the Albert-Ludwigs-Universität in Freiburg i. Br. with emphasis on macromolecular chemistry. - Diploma thesis on „Living anionic ring opening polymerisation of 1,1-dipropylsilacyclobutane” in the group of Prof. Dr. R. Mülhaupt

- Degree: Dipl. Chem., grade: 1,6

dr. Ria Kress*

BASF Coatings AG, Munster, Germany

*This lecture has been withdrawn from the program.

Title lecture

Innovative production process for pigmented powder coating

Author

A. Joch

Abstract

The design of an efficient process for the production of small batches up to 500 kg of powder coatings and the use of shear-sensitive effect pigments is a desired goal in modern powder coatings production technology. An innovative process – based on fluidised bed technology – will be illustrated. The goal was the development of a powder tinting system which is based on a typical powder coating particle size distribution showing no draw-backs to conventionally produced coloured powders. This process allows to create powder coatings with new or improved effect colours as well. The new „Tinting System” is based on core shell particles with typical powder diameters. The pilot system results in a standard powder (polyester with carboxyl-groups and a polyglycidyl ester hardener). A non-pigmented base powder is coated with a pigmented shell consisting of pigments, resin, hardener and additives. The colour adjustment process is advantageously done by mixing resins and pigments in a liquid phase. In addition the integration of effect pigments like aluminium flakes or micas works efficiently in this tinting process. Experiments with several attractive pigments even in a one-layer metallic powder system demonstrated exceptional results. The advantages of this innovative process versus the state of the art ”bonding process” could lead to the creation of exciting effect powders with a new level of performance profile.

dr. Baoshun Liu

Key Laboratory of Silicate Materials Science and Engineering, Ministry of Education, China, Wuhan University of Technology, Wuhan City, Hubei Province, P.R. China

Title lecture

Efficent degradation of aqueous methyl orange over TiO2 and CdS electrodes using photoelectrocatalysis under UV and visible light irradiation

Authors

Liping Wen, Baoshun Liu, Xiujian Zha

Abstract

A highly efficient photocatalytic course was realized using photoelectrocatalysis by combining titanium dioxide (TiO2) and cadmium sulphide (CdS) films. The TiO2 thin films were prepared on ITO glass substrates using d.c reactive magnetron sputtering, and the CdS thin films were deposited on ITO glass substrates by chemistry bath deposition (CBD). The X-ray diffraction (XRD), Raman, XPS, AFM and TEM were used to characterize the film structure and surface morphologies. The TiO2 and CdS films were used for anodes and cathodes in a three electrodes photoelectrochemical cell. Meanwhile, the UV and visible lights were used to illuminate the TiO2 and CdS films. Either TiO2 films or CdS films and Pt wire were used for anodes and counter electrode , then TiO2 films or CdS films electrodes were UV or visible lights irradiated, respectively. A series of bias powers were applied between TiO2 and CdS film electrodes.The experiments shows that the photoelectrocatalysis by the TiO2 and CdS films under double beam irradiation of UV and visible lights had higher reactivity than the sum of photoelectrocatalysis solely using TiO2 and CdS films. At last, the reaction mechanism was explained based on the model of the n-n diode for photocatalytic improvement.

Biography

EDUCATION

- 09/2003–06/2006 Ph.D Candidate in Wuhan University of Technology, Wuhan, China, Advisor: Prof. Xiujian Zhao

- 09/2000–06/2003 B. S. Degree in Wuhan University of Technology, Wuhan, China, Advisor: Prof. Xiujian Zhao

- 09/1996–06/2000 Bachelor Degree in Wuhan University of Technology, Wuhan, China, Advisor: Prof. Xinjian Jiao

RESEARCH WORK

7/2006–present Lecturer in Wuhan University of Technology, Wuhan City,

Hubei province, China

- Supported by National Natural Science Foundation of China (NSFC), 2008-2010, No. 50702041

- Supported by Key Laboratory of Silicate Materials Science and Engineering (Wuhan University of Technology),Ministry of Education, 2007-2008

- Supported by Nippon Sheet Glass Foundation (Japan), 2008-2009

TEACHING EXPERIENCE

Lecturer, Wuhan University of Technology, Wuhan City, Hubei province, China, 2006-present.

Developed teaching, leadership, and organizational skills as a lecturer in the Wuhan University of Technology, School of Material Science and Engineering

Courses Taught

- Modern Functional Material, undergraduate students.

- Professional English, engineering graduate.

- Experimental Teaching for using UV-vis and PL photospectrometer, undergraduate students.

RESEARCH EXPERIENCE

- Implemented two magnetron sputtering equipments and one includes an electron gun. Many works of My Doctor’s thesis were obtained using the magnetron sputtering equipments.

- Mastered Modern analysis techniques, including X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and others.

- Expertly Mastered the C++ languages, and can use the Visual C++ to implement numerical calculation related to my research subject.

dr. Jonathan W. Martin

National Institute of Standards and Technology (NIST) Gaithersburg, MD 20889, USA

Title lecture

Linking field and laboratory exposure and prediction long-term performance of an epoxy coating

Authors

J.W. Martin, T. Nguyen, X. Gu, J. Chin, B. Dickens, E. Byrd, D. Stanley

Abstract

A reliability-based methodology has been successfully employed in mathematically linking field and laboratory exposure results and in predicting the outdoor performance of a neat epoxy coating.

Laboratory aging tests were experimentally designed and exposed to wide range of extremely well-controlled temperature, humidity, spectral waveband, and spectral intensity conditions. Designed laboratory experiments were conducted in the NIST SPHERE, a 2-meter integrating sphere in which

1) each of above stated exposure variables were precisely, accurately, and independently controlled over long exposure periods and

2) all known sources of experimental error common to commercial exposure equipment have been eliminated and no new error sources have been introduced.

The laboratory experiments were specifically designed to validate the total dosage model, reciprocity law, and the additivity law, over wide temperature and relative humidity ranges. For the studied material, all three models appear to be valid. Epoxy coated specimens were exposed to 4 relative humidities, 4 temperatures, 4 ultraviolet wavebands, and 4 irradiance levels for each waveband. Numerous analytical chemical and physical measurements of degradation were taken on each specimen at numerous times throughout their exposures. Extensive efforts were made to ascertain the underlying failure mechanisms.

Outdoor exposure experiments were conducted on the NIST roof located in Gaithersburg, MD. This exposure site was instrumented to characterize the field exposure environment in exactly the same manner as the laboratory exposure environments. Specifically, the outdoor site monitored or estimated solar spectral irradiance, panel temperature, and panel moisture content every 12 minutes of every day. Field experiments were started at the beginning of each of 18 months over a three year period. Degradation of the exposed specimens was characterized in the same manner as the specimens exposed in the laboratory. Degradation data for every specimen was collected numerous times for each experiment.

Field and laboratory exposure results were linked by their failure mechanisms and via the total dosage model. Two cumulative damage models were developed to predict field performance–an analytical model and a neural network model. Both models assumed only that the total dosage and additivity law were obeyed and that the reciprocity law or a variant of the reciprocity law was valid.

Model parameters were estimated from laboratory exposure data. Estimates of field response for all 18 experiments were made from these parameterized models and from field exposure data for each experiment. Predictions from both models were excellent. The neural network model, being a data based model, predicted field degradation response slightly better than did the analytical model, but both estimates were well-within 10% of the actual field response data for all 18 field experiments.

It is concluded that the reliability-based methodology is capable of linking laboratory and field exposure data and of predicting the performance of coated specimens exposed in the field.

Biography

Dr. Jonathan W. Martin is the Group Leader of the Polymeric Materials Group at NIST since 1994. He also acts as the Director of the NIST/Industry Coatings Service Life Prediction Consortium. His technical interests include the application of reliability theory and life testing analyses techniques in predicting the service life of polymeric materials and in developing informatics and high-throughput analytical measurement capabilities at NIST. Dr. Martin was an Associate Editor of the Journal of Materials in Civil Engineering and is currently on the editorial board of the Journal of Coatings Technology. He is the recipient of an IR-100 award, the Bronze Medal and the 2004 William P. Slichter Award from the US Department of Commerce, is a recipient of the 2003 and 2004 Roon Foundation Awards, and the 2004 Federation of Societies of Coatings Technology John A. Gordon Award. Dr. Martin has over 120 publications, two patents, and has given numerous presentations both nationally and internationally. He has also co-chaired three international symposia on the topic of the Service Life Prediction of Polymeric Materials; two of these proceedings have been published in book form and the third proceedings is scheduled to be published in 2005.

dr. Patrice Roose

Cytec Surface Specialties, Drogenbos, Belgium

Title lecture

Radiation curing technology: an innovative and attractive technology for metal coating

Authors

I. Fallais, P. Roose, M. Heylen, C. Vandermiers, M.-G. Olivier, M. Poelman

Abstract

For several decades now, radiation curing technology has been successfully used in numerous wood and paper coating applications as well as in printing inks. The radiation curing formulations are 100 % solid, environmentally friendly compositions which produce no volatiles and require less energy and space for coating than conventional solvent based technologies. These advantages also make radiation curing formulations interesting for metal coating markets. In the case of the most demanding metal applications where excellent adhesion, flexibility and corrosion resistance are required, some performances improvements are needed. Typical radiation curable formulations are based on (meth)acrylated oligomers and reactive diluents which when cured form a highly cross-linked network having good surface properties such as chemical resistance, scratch resistance, abrasion resistance and surface hardness. A high cross-link density is also associated with limited flexibility and a certain level of film shrinkage; this reduces adhesion to non porous metallic substrates. Recently new tailor made (meth)acrylated oligomers have been developed which have significantly improved performance, hence broadening the uses of the radiation curing technology in metal coating applications.

In this paper, three fairly simple clear-coat systems are studied.

They are characterized and ranked in terms of conversion, molecular characteristics such as molecular weight and double bond content, shrinkage, swelling and visco-elastic characteristics measured on 100 µm free-standing films.

Their barrier properties on hot dip galvanized steel at thicknesses between 20 and 100 µm are studied by electrochemical impedance spectroscopy.

Finally, practical performance tests (solvent resistance, Erichsen, T-bend, reverse impact, salt-spray tests) are performed on the three systems on coatings of 20 and 100 µm applied on hot-dip galvanised steel. These are the tests which are used to set up coating product profiles in the metal industry. The results will be discussed within the framework of the preceding observations.

Biography

Patrice Roose earned a PhD in physics from the Vrije Universiteit Brussel in 1989 in the field of NMR relaxation applied to colloidal systems and protein solutions. In 1998, he started in the main analytical laboratory of UCB Chemicals located in Drogenbos, Belgium where he was in charge of the elemental analysis section. Subsequently, his duties were extended to include physico-chemical characterisation of dispersed media, thermal, mechanical, viscoelastic analysis as well rheology and surface energetics as part of the analytical department of Cytec Surface Specialties today. Over the years, Patrice Roose has strongly been involved in research for pressure sensitive adhesives, polyester powder coatings and radiation curable coating systems which has led to more than 20 scientific papers and conference proceedings as well as a few international patents.

Masaaki Saika

SR Institute, Kansai Paint Co. LTD. Hiratsuka-shi, Kanagawa, Japan

Title lecture

CO2 Emission reducible coatings based on modified corn-starch

Author

Masaaki Saika

Abstract

Increased consumption of fossil fuel such as petroleum, coal etc. turns into an increase of carbon-dioxide emissions to atmospheric environment, and that increase is said to be a cause of global warming. This global warming is further said to cause decrease of ice around Arctic Circle, huge hurricanes, spread of desertification and other abnormal weathering phenomena. Then, reduction of carbon-dioxide emissions has been the one of the biggest issues for human beings. Responding the above situation, many research works have been started to utilize plant-origin materials. The plant-origin materials are so-called ”carbon neutral materials”, since carbon contained in the materials are originated from carbon dioxide gas absorbed during their growth. We have developed a coating based on modified corn-starch without spoiling any required performance levels, and the developed coating has already been commercialized for a home electric appliance

Professor dr. Masamitsu Shirai

Osaka Prefecture Univeristy, Department of Applied Chemsitry, Osaka, Japan

Title lecture

i-Line sensitive photoacid generators for UV curing

Author

Masamitsu Shirai

Abstract

UV curing systems based on cationic processes are very significant because the systems have several advantages, compared to the radical processes. Photoacid generators (PAGs) are essential for the cationic UV curing system including epoxides and vinyl ethers. Although many types of PAGs have been developed, most of them are not sensitive to i-line (365 nm) of a high-pressure mercury lamp. In this study, non-ionic and ionic PAGs that are thermally stable and highly sensitive to i-line were designed and synthesized. Furthermore, photochemistry of these PAGs and their applications to photocrosslinking systems based on epoxy-containing polymers and oligomers were studied.

Biography

Masamitsu Shirai received his Ph.D. degree from Osaka Prefecture University (OPU) in 1978. After working as an assistant professor and then an associate professor at OPU, he was promoted to a professor of applied chemistry at OPU in 1997. He spent his early career as a postdoctoral fellow (1978-1979) at the State University of New York at Syracuse, New York, USA. His research interests include synthesis and applications of photosensitive polymeric materials, especially photoresists, photoacid generators, photobase generators, UV curing materials, and photodegradation and stabilization mechanisms of polymeric materials. He has published more than 250 research papers including reviews and books.

Per Aggerholm Sørensen (MSc)

Department of Chemical Engineering, Technical University of Denmark, Building 229, DK-2800 Kgs. Lyngby, Denmark

Title lecture

Influence of substrate characteristics on cathodic delamination of anticorrosive coatings

Authors

P. A. Sørensen, S. Kiil, K. Dam-Johansen, C. E. Weinell

Abstract

Despite improvement in coating technologies, problems continue to exist in long-term protection of steel structures (e.g. offshore oil rigs, wind turbines and ballast tanks) against their environments. For organic anticorrosive coatings in electrolyte solutions (e.g. seawater), cathodic delamination is one of the most severe types of failure. Although significant advances in understanding the mechanisms and modes of failure have been made, the detailed mechanism of cathodic delamination remains unknown.

The purpose of this work is to investigate the mechanism of cathodic delamination. Experimental investigations, with selected coating system, show that disbondment of organic coatings is mainly controlled by diffusion of cations from a defect to the delamination front and not through the intact or disbonded coating. Furthermore, an ongoing delamination process was found to be inhibited, when the anodic reaction was suppressed. The influence of substrate surface characteristics on the rate of cathodic delamination was also investigated. Steel substrates with a higher degree of roughness were found to decrease the rate of delamination. Through experimental analysis of the surface characteristics, the disbondment results are related to effective diffusivity of cations at the coating-steel interface.

dr. Ananda Kumar Srinivasan

Department of Chemistry, Anna University, Chennai – India

Title lecture

Development and characterization of phosphorus containing siliconized epoxy resin coatings

Authors

Ananda kumar Srinivasan, Denchev Z.latan, Alagar Muthukaruppan

Abstract

A novel siliconized epoxy matrix resin coating was developed by reacting diglycidyl ethers of bisphenol A (DGEBA) type epoxy resin with hydroxyl terminated polydimethylsiloxane modifier, using g-aminopropyltriethoxysilane crosslinker and dibutyltindilaurate catalyst. The siliconized epoxy resin was cured with 4, 4-diaminodiphenylmethane (DDM), DOPO-diamine (DOPO-2NH2), and Polyhedral oligomeric silsesquioxane amine (POSS-amine).

The DOPO-diamine and POSS-amine cured epoxy and siliconized epoxy resins exhibit better flame retardant behaviour than DDM and cured resins. The thermal stability and flame retardant property of the cured epoxy resins were studied by thermal gravimetric analysis (TGA) and limiting oxygen index (LOI). The glass transition temperatures (Tg) were measured by differential scanning calorimetry (DSC) and the surface morphology was studied by scanning electron microscope (SEM). The heat deflection temperature (HDT) and moisture absorption studies were carried out as per ASTM standards. The thermal stability and flame retardant properties of the cured epoxy resins were found to be improved by the incorporation of both silicone and phosphorus into the epoxy skeleton. The synergistic effect of silicone and phosphorus enhanced the limiting oxygen index values that were observed for siliconized epoxy resins cured with phosphorus containing diamine compounds.

Key words: siliconized epoxy resin, epoxy resin, curatives, thermal stability, flame retardancy and limiting oxygen index

References

- Lee H, Neville K. Hand book of epoxy resins, McGraw-Hill Book Company: 1967 New York.

- Ananda kumar S, Sankara Narayanan T. S. N. Progress in Organic Coatings.2002; 45:323

- Hsiue GH, Liu YL, Tsiao J. J. Appl. Polym. Sci. 2000; 78:1

- S. Ananda kumar, Z. Denchev and M. Alagar, (2006), ”synthesis and thermal characterization of phosphorus containing siliconized epoxy resins”, European Polymer Journal, 42,10, 2419-2429.

- Sung H, Lin CY. European Polymer Journal. 1997a; 33:903.

dr. Per-Erik Sundell

SSAB Tunnplat AB, Sweden

Title lecture

UV-cured coil coatings - product performance and outdoor durability

Author

Per-Erik Sundell

Abstract

Enhanced properties of coil coated steel can be realised by the introduction of alternative curing technologies such as electron beam, ultraviolet light and near infrared radiation. Fully non-volatile formulations, applied and cured in a few seconds allow for the enhancement of a manifold of desirable properties. Extreme hardness in combination with good flexibility, effective barriers towards aggressive environment, aesthetic appeal as well as almost any functional surface is plausible assets of future coil coatings. Particularly, exterior coatings that endure long wet times and extended periods of solar radiation as well as attractive and functional surfaces that break ways into new applications of pre-coated steel are highly interesting. Benefits of combining thermal and UV-curing formulations in a multilayer coating product and examples of enhanced properties as well as the long term, exterior durability of such systems will be discussed.

background

- MSc in Chemical Egineering, Majoring in Polymer Science, The Royal Instistute of Technology, Stockholm, Sweden, 1981 – 86

- PhD in Polymer Technology, The Royal Instistute of Technology, Stockholm, Sweden, March 30, 1992; Thesis: ”Cationic Polymerization of Vinyl Ethers using Iodonium and Sulfonium Salts”

- Post-doc at University of Southern Mississippi, Hattiesburg, MS, US. Prof. Charles Hoyle. 1990 – 91.

- Employed at SSAB Tunnplåt AB, Borlånge, Sweden, 1992 – present

dr. Stacy M. Trey

Dept. of Fiber and Polymer Technology, The Royal Institute of Technology, Stockholm, Sweden

Title lecture

Effect of residual stress build-up and cure shrinkage in UV cured acrylate resins on adhesion to SMC substrates

Authors

Stacy M. Trey, Kamyar Alavi, Mikael Lundstrom, Daniel Ståhlberg, Mats Johansson

Abstract

Sheet molded compound (SMC) is a highly filled, glass fiber reinforced, thermoset material used in trim and body panel automotive parts. When SMC-substrates are coated with conventional thermally cured paints, inherent porosity and entrapped volatiles of the substrate result in popping (”paint pops”) defects. UV-curable primers provide an order of magnitude reduction of paint defects in SMC coatings, but typically have poor adhesion. The present study investigates a dual-cure approach to address both the popping defect problem and the poor adhesion of UV-curable primers. An initial UV-curing will seal the SMC-surface and subsequent thermal cure will improve the adhesion.

A series of di- and triacrylate resins is studied, showing the effect of resin functionality and resulting degree of cure shrinkage on the adhesion of the coatings to SMC substrates. The effect of resin functionality and isocyanate content (0-5 wt%) on cure shrinkage is determined by the dynamic shear modulus and film thickness, measured by a dynamic torsional rheometer. Gelation kinetics and equilibrium conversion are also examined as a function of temperature and functionality of the resins. The in-plane stress of the films is measured independently by the bilayer beam bending technique and compared to predicted values calculated from the storage modulus and the thickness contraction after gelation. The present study demonstrates that a UV-primer can solve several of the present problems with SMC-coatings as well as impart the key parameters in the design of such a primer system.

Biography

Dr. Stacy Trey received her B.S. in Chemistry at the State University of New York at Oswego in 2002. She then graduated with her Ph.D. in Polymer Science and Engineering in 2007 from The University of Southern Mississippi where her area of study was the synthesis and characterization of polyurethane poly(ethylene glycol) hydrogel films and microgels. After graduating she worked for 3 months at the startup company Ablitech Inc. in Hattiesburg, Mississippi where she synthesized small molecules for application in polymer materials for biomedical applications.

She is now at The Royal Institute of Technology as a post-doc for Mats Johansson in the Coatings Technology Group of the Fiber and Polymer Technology department where she is working in the area of acrylate and thiol-ene UV curable films. More specifically within these areas, the adhesion modification of acrylate coatings with isocyanate and thiol additives for use as primers on sheet molded composites. Additionally work has begun on the addition of ene and acrylate functionalized dendrimers into thiol-ene crosslinked films and the resulting structure-property relationship.

dr. Anne-Lise Troutier

University Blaise Pascal, Clermont-Ferrand, France

Title lecture

Layered particle based polymer composites for coatings: Part I – Evaluation of inorganic layered particles

Authors

Horst Hintze-Bruening, Anne-Lise Troutier, Fabrice Leroux

Abstract

Layered double hydroxides (LDH) suitable for the formulation of polymer composites are

designed and characterized.

Polymer nanocomposites based on intercalated and exfoliated layered inorganic particles have increasingly attracted research activities due to improved properties of the resulting polymer materials like stiffening, diffusion barrier and thermal stability. The vast majority of such nanocomposites is based on smectite clays like Montmorillonite, an aluminosilicate bearing an anionic layer charge.

One of the main challenges for an effective dispersion of those particles in the polymer matrix still remains the design of an appropriate interphase between polymer and particle.

We show that inversely charged layered particles are accessible in the form of synthetic layered double hydroxides whose crystallinity and layer charge density can be varied over a broad range by the selection and the ratio of the cations and that their lateral dimensions as well as their surface chemistry are tunable via the synthesis parameters and the anions chosen.

We believe our results will point out a feasible route towards a toolbox of a new class of inorganic layered particles for the manufacturing of polymer nanocomposites.

Biography

Anne-Lise Troutier

- 1998-2002 : chemistry studies at the Ecole Nationale Superieure de Chimie de Montpellier (France)

- 2002-2005 : Ph D. on the Elaboration of core-shell nanoparticles for diagnostic tests (Lyon)

- 2006-present : post-doctoral position in Laboratoire des Matériaux Inorganiques (Clermont-Ferrand) in cooperation with BASF Coatings AG

Björn Weber (MSc)*

University Paderborn, Germany

*During the conference this lecture was given by professor Wolfgang Bremser from Paderborn University, Germany.

Title lecture

Creating new materials with melamine resins

Authors

Björn Weber, Wolfgang Bremser, Karl Hiltrop

Abstract

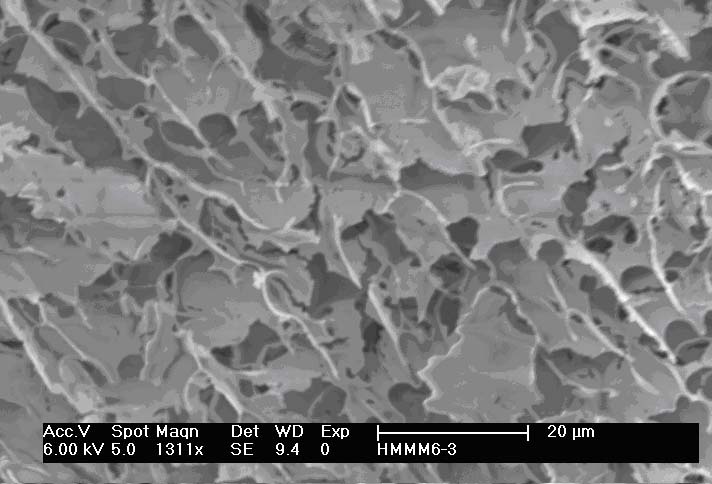

The acid catalyzed condensation of well known melamine resin of HMMM type in aqueous phase leads to new functional particles and up to now unknown lamellar mesoscopic gels. The gels are used as templates for a subsequent mineralization process in order to create an organic-inorganic hybridmaterial.

The particle formation starts with non spherical nanoparticles which could be functionalized for further coating applications. Lamellar particles in the µm-range with hexagonal symmetry could be isolated. First investigations give an indication for an energy minimized layer by layer condensation of the melamine crosslinker molecules.

Out of these platelet structures as precursors a mesoporous gel with essentially lamellar walls and pore sizes between 100 nm – 10 µm is formed. The architectior can be controlled over a wide range by concentration and the use of crosslinkable dispersions.

Inside the pores of the gel calcium carbonate crystals with different morphologies are formed either by a double diffusion mineralization process or by the use of polymer induced liquid precursors. The structural and mechanical properties of these materials are investigated.

|

|

| Hexagonal melamine particle | Lamellar melamine gel |

|

|

| Mineralization in curved template 1 | Mineralization in lamellar template |

Professor Dean C. Webster

Department of Coatings and Polymeric Materials, North Dakota State University, 1735 NDSU Research Park Drive, Fargo, ND 58105 USA

Title lecture

Hybrid sol-gel coatings from glycidyl carbamate functional resins

Authors

Dipak Chattopadhyay, Autumn Zakula, Dean C. Webster

Abstract

Glycidyl carbamate (GC) functional resins are unique systems which combine epoxy crosslinking with polyurethane performance. GC functional resins can self-crosslink at elevated temperatures or crosslink with amines at ambient temperatures. It is possible to synthesize a variety of GC functional resins, leading to the ability to tune the properties over a wide range. Hybrid sol-gel coatings contain inorganic domains covalentally attached to the matrix resin. We have explored two approaches for the synthesis of hybrid coating systems based on glycidyl carbamate resins. In the first approach, a multifunctional GC resin is reacted with an aminoalkyl silane, amine crosslinker, and tetraethylortho silicate to form a crosslinked sol-gel hybrid coating. In the second approach, a silane-modified GC resin is first synthesized which has both GC functional groups and silane functional groups. These resins are then crosslinked using a combination of an amine crosslinker and tetraethylortho silicate. With both approaches a large number of compositions have been systematically prepared, key coatings properties determined, and structure-property relationships determined. The coatings have good hardness, solvent resistance, and good adhesion to aircraft aluminum.

Biography

Dean Webster is a Professor in the Department of Coatings and Polymeric Materials at North Dakota State University He received a B.S. in Chemistry and a Ph.D. in Materials Engineering Science both from Virginia Tech. Prior to joining NDSU in 2001 he worked for Sherwin-Williams at their Central Research Laboratories in Chicago and at Eastman Chemical Company in Kingsport, Tennessee. His current research interests include the design of high performance polymer and coating systems, use of high throughput methods in the development of new materials, low surface energy coatings, radiation curable polymer systems for microelectronics, and the use of natural products in materials.

dr. Mariëlle Wouters

TNO Science & Industry, Eindhoven, The Netherlands

Title lecture

Preparation and properties of a novel remendable coating concept

Authors

Mariëlle Wouters, Hartmut Fischer, Joyce van Zanten, Eric Craenmehr, Niki Stroeks, Karin Tempelaars

Abstract

Key properties of organic coatings, like for instance mechanical strength, solvent resistance and barrier properties are greatly influenced by the polymeric structure in the coating layer. In general, a 3-dimensional polymeric network gives the best properties and therefore most performance coatings have a 3-dimensional network structure. But upon damage these systems are not easily repaired.

Through molecular design in combination with different synthetic routes, a series of new building blocks for coatings were prepared that are capable to repair a damaged layer by the formation of a covalent bond upon cooling of the coating formulation. By the incorporation of various functionalities the properties of the final coatings can be tuned.

The self-healing concept was proven by various techniques, and it was proven that their processing windows can also be tuned. The thermally remendable crosslinked materials show interesting properties for coatings in various applications, other areas of applications are possible.

dr. Mikhail L. Zheludkevich

DECV/CICECO, Universidade de Aveiro, Aveiro, Portugal

Title lecture

LDH-based nanocontainers as anticorrosive pigment for protective coatings

Authors

M. L. Zheludkevich, S. K. Poznyak, L.M. Rodrigues, L.F. Dick, M. G. S. Ferreira

Abstract

The passive corrosion protection is normally achieved by deposition of organic or hybrid polymer coatings as a barrier layer preventing contact of the metallic substrate with corrosive environment. The active corrosion protection aims at a decrease of the corrosion rate when the main barrier is damaged and corrosive species become in contact with the substrate. This can be achieved by the addition of corrosion inhibiting compounds to the protection system. However, direct mixing of an inhibitor with coating formulations can lead to the important drawbacks decreasing barrier properties of coating and diminishing activity of the inhibitor. The problem of coatings with active protection function becomes more acute due to the up coming restriction of the use of chromates, which are known as the most effective inhibitors but are strongly carcinogenic. The development of a new approach to introduce environmentally-friendly corrosion inhibitors, which can provide prolonged and even ”smart” release of the inhibiting species on demand and prevent interaction of inhibitor with coating formulation, becomes an important issue for many industries where an adequate corrosion protection is needed.

The present work shows a new contribution to the development of a novel protective system with self-healing ability that composed of polymer coating doped with nanocontainers that release entrapped corrosion inhibitor in response to presence of corrosive species. The new nanocontainers for organic and inorganic corrosion inhibitors were developed in this work employing layered double hydroxide (LDH) as nanocarriers for immobilization of active compounds. Mercaptobenzothiazole, 8-hydroxiquinoline and vanadetes were used here as corrosion inhibitors. The corresponding ionic forms of these compounds were introduced to the interlayer space of LDH structure by ion-exchange.

The coating with the nanocontainers reveals enhanced long-term corrosion protection of AA2024 in comparison with the undoped films. This effect is obtained due to regulated release of the corrosion inhibitor triggered by the presence of corrosive anions such as chlorides. The approach described herein can be used in many applications where active corrosion protection of materials is required.

Biography

Dr. Mikhail Zheludkevich is currently CICECO researcher at University of Aveiro, Aveiro, Portugal. He is leader of Surface Engineering and Corrosion Protection group. In 1998 he graduated from Belarusian State University. In 2002 he took his PhD degree in physical chemistry at the same University. He also is part-time assistant professor in the University of Aveiro teaching corrosion science. His current interests include development of novel self-healing protective coatings on the basis of ”smart” nanoreservoirs with active healing agents.

dr. ing. Thomas Zwieg

Larsen Strings A/S, Sonderborg, Denmark

Title lecture

Optimisation of tone quality or timbre of musical strings for bowed instruments

Author

Thomas Zwieg

Abstract