Posters COSI 2010

- The Poster Session is scheduled for Tuesday 29 June 2010: 14:00 -15:30 hrs & 18:00 - 22:00 hrs and will take place in Hotels van Oranje, in the combined Emma / Wilhelmina and Juliana Zaal.

- Amira Abou-Hamdan, Chemspeed Technologies AG, Augst, Switserland, Faster & Better Synthesis, Formulation, Application and Testing of Paints & Coatings by Automated High-Output Solutions

- Indu Babu, Eindhoven University of Technology, Departement of Chemical Engineering and Chemitry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands, Highly flexible 0-3 PZT/PDMS composite films

- Prof.Dr. Massimiliano Barletta, Università degli Studi di Roma Tor Vergata, Dipartimento di Ingegneria Meccanica,Roma, Italy, Manufacture and characterization of free-standing epoxy-polyester films

- Denise Bellisario, Università degli Studi di Roma La Sapienza, Dipartimento di Meccanica ed Aeronautica, Roma, Italy, Effects of IR pre-curing conditions on wear resistance of metal flakes powder coatings

- Camille Carcouët, Eindhoven University of Technology, Department of Chemical Engineerig and Chemistry, Laboraroty of Materials and Interface Chemistry, Eindhoven, The Netherlands, Nature-inspired superhydrophobic surfaces from raspberry-like particles

- Belén Díaz-Benito, Materials Science and Engineering Department, Universidad Carlos III de Madrid, Madrid, Spain, Deposition of g-methacryloxypropyltrimethoxysilane coatings on 6063 aluminium alloy treated with atmospheric plasma: characterization by FTIR and contact angle measurements

- Dr Christine Dumas, Groupe des Procédés de Séparation (GPS), IPHC-DSA, UMR CNRS 7178, Université de Strasbourg, Strasbourg Cedex 2, France, Hydrogen permeation as an indicator to evaluate the porous/dense character of multiple nickel autocatalytic deposits

- Roland Emmerich, Robert Bosch GmbH, Packaging Technology, Bosch Lab Systems, Waiblingen, Germany, Experience with Automated Development and Spray Application of Coatings

- Dr. Bart Erich, TNO Built environment and Geosciences, Delft, The Netherlands / Eindhoven University of Technology, Department of Physics, Group Transport in Permeable Media, Eindhoven, The Netherlands, Water transport through coatings into wood

- Dr. Catarina Esteves, Eindhoven University of Technology, Departement of Chemical Engineering and Chemitry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands, Superhydrophobic self-replenishing coatings through the design of surface topology and chemistry

- Emilie Faure, Center for Education and Research on Macromolecules (CERM), University of Liège, Belgium, A green and refillable antibacterial coating for stainless steel

- Michele Fedel, Department of Materials Engineering and Industrial Technologies, University of Trento, Trento, Italy, Silicon alkoxides sol-gel hybrid coatings containing clay nanoparticles for corrosion protection of galvanized steel

- Dr. Adolphe Foyet, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands, Barrier properties of a chromate free primer on Al-2024

- Santiago Garcia Espallargas, Delft University of Technology, Department of Aerospace Materials and Manufacturing, Kluyverweg 1, 2629 HS, Delft, The Netherlands, Self-healing anticorrosive organic coating based on the release of a reactive Silyl Ester

- Argyrios Georgiadis, University of Surrey, Department of Physics, Faculty of Engineering and Physical Sciences, Guildford, UK, A new method for making hard, No-VOC waterborne coatings

- Dr.ir. Nathalie De Geyter, Department of Applied Physics Faculty of Engineering - Ghent University (UGent), Belgium, Plasma-assisted deposition of polymethyl methacrylate onto TiO2 substrates

- Prof.Dr. Mahmood Ghoranneviss, Islamic azad University, Plasma Physics Research Center, Science and Research Branch, Tehran, Iran, Investigation on Dye ability and Antibacterial activity of nano- Layer Platinum Coated Polyester fabric Using DC Magnetron Sputtering

- Ismail Dogan Gunbas, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Polymer Chemistry, Eindhoven, The Netherlands, Maleic Anhydride Based Copolymer Dispersions for Surface Modification of Polar Substrates

- Dr. Claudia Haensch, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands, Screening of different epoxide/ amine combinations for the preparation of coating materials onto aluminum alloy 2024 substrates

- Dr. Mijeong Han, Advanced Materials Division Korea Research Institute of Chemical Technology, Yuseong-gu, Daejeon, South Korea, Corrosion and wear resistance of multi-functional organic-inorganic hybrid coatings

- Dr. Marc Herold, Bühler PARTEC GmbH, CTO Business Unit PARTEC- Bühler AG, Saarbrücken, Germany, Superior eco friendly waterborne coatings due to nanoparticle technology

- Eliana Ieva, Solvay Solexis, Spinetta Marengo, Italy, Preparation of durable superhydrophobic surface by sol-gel method with water glass and citric acid

- Dr. Byung-Koog Jang, Fine Particle Processing Group, Nano Ceramics Center National Institute for Materials Science (NIMS), Tsukuba, Ibaraki, Japan, Microstructure of Nanoporous Zirconia Coatings Fabricated by EB-PVD

- Prof.Dr.Yeon Gil Jung, School of Nano & Advanced Materials Engineering, Changwon National University, Changwon, Republic of Korea, Dual Coating Process of High Functional Reinforcement Phase in Metal Matrix Composite

- Dr. Eun-Hee Kim, School of Nano & Advanced Materials Engineering, Changwon National University, Changwon, Republic of Korea, Preparation of Ni-Coated TiC Particles using Potential Hydrogen (pH) for Dispersion into a Molten Metal

- Jae-Hyung Kim, School of Nano & Advanced Materials Engineering, Changwon National University, Changwon, Republic of Korea, Microstructural evolution and thermal stability of layered thermal barrier coatings in cyclic thermal exposure

- Dr. Hans Kranenburg, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands, Self-healing adhesion of coating networks

- Alicja Krella, The Szewalski Institute of Fluid-Flow Machinery, Polish Academy of Sciences, Gdansk, Poland, Degradation model of hard coatings under cavitation action

- Patricia Lammel, EADS Innovation Works, Dept. Metallic Technologies and Surface Engineering, Munich, Germany, Solid particle erosion behaviour of nickel- and chromium based coatings

- Sang-Yeop Lee, School of Nano & Advanced Materials Engineering, Changwon National University, Changwon, Republic of Korea, Microstructural evolution and oxidation behavior of thermal barrier coating system with buffer layer in thermal exposure

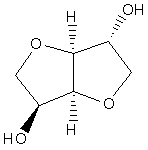

- Yingyuan Li, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Polymer Chemistry, Eindhoven, The Netherlands, Waterborne polyurethane dispersions based on dimer fatty acid-based diisocyanate and isosorbide

- Prof.Dr. Ronaldo D. Mansano, Laboratory of Integrated Systems (LSI) - Polytechnic SchooL of University of São Paulo, São Paulo -SP Brazil, Micropatterning of single-walled carbon nanotubes forest

- Prof.Dr. Marcos Massi, Technological Institute of Aeronautics, Plasma and Processes Laboratory, Physics Department, S. J. dos Campos, Brazil, Comparison between conventional and hollow cathode magnetron sputtering systems to deposition of photocatalytic anatase titanium dioxide thin films

- Prof.Dr. Marcos Massi, Technological Institute of Aeronautics, Plasma and Processes Laboratory, Physics Department, S. J. dos Campos, Brazil, Effects of Microwave Excited Plasma Treatment on Adhesion Properties of EPDM rubber

- Daisaku Matsukawa, Department of Applied Chemistry, Osaka Prefecture University, Nakaku, Sakai, Osaka, Japan, Chain Propagation in UV Curing of Difunctional Methacrylates

- Christopher Mealy , Fire Protection Engineer ,Hughes Associates, Inc. Baltimore, Maryland, USA, Intumescent coatings for application on Munition containers

- Dale Molloy, School of Mechanical and Aerospace Engineering, Queen´s University of Belfast, Ashby Building, Belfast, UKThermal analysis of brush plated nickel sulfamate coatings

- Dr. Rino Morent, Department of Applied Physics Faculty of Engineering - Ghent University (UGent), Belgium,Allylamine plasma polymer films for biomedical applications

- Dr. Ana Paula Mousinho, Laboratory of Integrated Systems (LSI) - Polytechnic SchooL of University of São Paulo, São Paulo -SP Brazil, Stress analyze of the diamond-like carbon films using raman spectroscopy

- Dr. Ana Paula Mousinho, Laboratory of Integrated Systems (LSI) - Polytechnic SchooL of University of São Paulo, São Paulo -SP Brazil, Micro-raman spectroscopy used for analyzing the diameter distribution of high-aligned single-walled carbon nanotubes

- Arturo Muñoz-Castro, Instituto Nacional de Investigaciones Nucleares, México DF, Surface PIII modification of CpTi for dental applications

- Dr. K. S. Nagaraja, Department of Chemistry, Loyola Institute of Frontier Energy, Loyola College Chennai, India, Formation of SiC(O) by plasma assisted liquid injection chemical vapor deposition (PA-LICVD)

- Tatyana Nesterova, Technical University of Denmark, Department of Chemical and Biochemical Engineering, Lyngby, Denmark Synthesis of durable microcapsules for self-healing anticorrosive coatings

- Dr. Naofumi Ohtsu, Kitami Institute of Technology, 165 Koen-cho, Kitami, Hokkaido, Japan, Calcium titanate coating on titanium by simple chemical treatment using calcium-hydroxide slurry

- Önnaz Özkanat, Materials Innovation Institute (M2i), Delft, The Netherlands & Delft University of Technology, Department of Materials Science and Engineering, Delft, The NetherlandsA combined FTIR-RAS and macroscopic adhesion study of the interfacial bonding of epoxy coatings on pretreated AA2024-T3

- Bahram Ramezanzadeh, Amirkabir Universiyy of Technology, Polymer and Color Engineering, Department of Polymer and Color Technology, Tehran, Iran, Comparison the corrosion performance of trivalent and hexavalent chromium based conversion coatings on steel

- Dr. Zahra Ranjbar, Institute of Colorants, Paints and Coatings, Department of Surface Coatings and Corrosion, Tehran, Iran, Synthesis and Characterization of diethylene glycol monobutyl ether -Blocked Diisocyanate Crosslinkers

- Celia Ribes, Instituto de Technología Cerámica, Asociacion de Investigación de las Industrias Cerámicas, Universitat Jaume I. Castellón, Spain Relation between the scratch resistance and the chemical structure of organic-inorganic hybrid coatings

- Vinicius Rizzo, Laboratory of Integrated Systems (LSI) - Polytechnic SchooL of University of São Paulo, São Paulo -SP Brazil, Electro-optical sensitive Diamond-Like Carbon (DLC) coatings deposited by reactive magnetron sputtering for electronic devices application

- Matthias Rydzek, Bayerisches Zentrum fuer Angewandte Energieforschung e.V., Abteilung: Funktionsmaterialien der Energietechnik, Bavarian Center for Applied Energy Research, Division: Functional Materials for Energy Technology, ZAE Bayern, Wuerzburg, Germany, Comparative Study of Sol-Gel Derived Tin-doped Indium- and Aluminum-doped Zinc-Oxide Coatings for Electrical Conducting and Low-Emitting Surfaces

- Sudeshna Saha, Université du Québec a Chicoutimi, Canada Photo-stabilization of Acrylic Polyurethane Coatings for Exterior Application on Wood Using Bark Extract

- Alireza Salehi Movahed, Wallenberg Wood Science Centre (WWSC) and, Department of Fibre and Polymer Technology, School of Chemical Science and Engineering. KTH, Royal Institute of Technology. Teknikringen 56-58, SE-100 44 Stockholm, Sweden Effect of phenolic lignin structures on the oxidation of unsaturated fatty acids

- Mahdi Samadzadeh, Petroleum University of Technology, Abadan, Iran, Tung Oil: An Autonomous Healing Agent for Self Healing Coatings Based on Microcapsules as Core Material

- Jayaprakasam Selvakumar, Department of Chemistry, Loyola Institute of Frontier Energy, Loyola College Chennai, India, Evaluation of Vapor pressure measurements of M(tmhd)x [M= La(III), Sr(II) and Mn(III); tmhd - 2,2,6,6-tetramethyl-3,5-heptanedione] for Plasma-assisted LICVD process of metal oxide thin films

- Sheila Shahidi, Technical University of Liberec, Department of Textile Chemistry, Faculty of Textile, Liberec, Czech Republic, Influence of plasma sputtering treatment on wool natural dyeing and their antibacterial activity

- Peyman Taheri, Materials Innovation Institute (M2i), Delft, The Netherlands, and Delft University of Technology, Department of Materials Science and Engineering, Delft, The Netherlands, Evaluation of interfacial bonding of succinic acid on pure zinc by means of XPS and FTIR

- Prof.Dr. David I. Tetelbaum, Leading Researcher, Physico-Technical Research Institute, of University of Nizhny Novgorod, Nizhny Novgorod, Russia, Unusual influence of weak light irradiation on defect and defect-related properties of metal foils and semiconductor wafers covered with thin dielectric films

- Prof.Dr. Funda Tihminlioglu, Izmir Institute of Technology, Chemical Engineering Department, Urla Izmir, Turkey, A Novel Biodegradable Polymer Nanocomposite Coating for the Protection of Stone Monuments

- H. Vakili Tahami, Surface Coatings and Corrosion Department, Iran Color Research Center, Tehran, Iran, Colloid stability and electrokinetic characterization of waterborne epoxy amine adducts

- Jesus Manuel Vega, CENIM/CSIC, Departamento de Ingeniería de Materiales, Degradación y Durabilidad, Madrid Spain, Paint systems formulated with calcium-exchanged silica pigment. Effect of steel surface preparation in the anticorrosive behaviour

- Perumal Venkatesan, Central Electrochemical Research Institute, Karaikudi,India, Corrosion Behavior of reinforcement with speciality coating embedded in concrete and Exposed At Atmospheric, High Tide Levels And Immersed In Seafloor For Four Years

- Dr. Mariëlle Wouters, TNO Science and Industry, Eindhoven, The Netherlands, Digital Dyeing - towards a more environmental friendly functional fabric

- Te-Hui Wu, Technische Universiteit Eindhoven, Departement of Chemical Engineering and Chemistry, Laboratoyr of Materials and Interface Chemistry, Eindhoven, The Netherlands, A DSC isothermal study on the curing kinetics of epoxy/ amine/ carbon black system during the formation of nanocomposite

- Lee Ying-Chieh, Department of Materials Engineering National Pingtung University of Technology and science, Pingtung, Taiwan, R.O.C., The Effect of Cu Doped on Microstructure and Phase Transformation of ZnTiO3 Thin Films Prepared by RF Magnetron Sputtering

- Ju Young Yook, Hybrid Materials Research Center, Korea Institute of Science and Technology, Seoul, Korea, Epoxy Type Sol-Gel Coating on Poly(ethylene terephthalate) Surface Treated with Nitrogen-Containing Plasma

- Dr. Jörg Ulrich Zilles, Quarzwerke GmbH, High Performance Fillers, Frechen, Germany, Highly transparent Micro Fillers for the Enhancement of UV-Curable Lacquers

- *Only registerd participants with a poster presentation will be shown on the website.

Amira Abou-Hamdan

Chemspeed Technologies AG, Augst, Switserland

Title lecture

Faster & Better Synthesis, Formulation, Application and Testing of Paints & Coatings by Automated High-Output Solutions

Authors

Olaf Köhler

Abstract

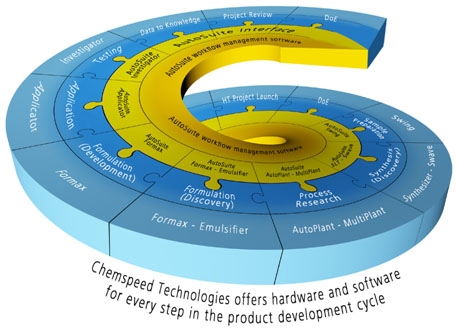

Starting in the area of pharmaceutical industry, automation technologies have changed scientists´ daily laboratory routine in a variety of research areas. Nowadays emphasis is placed on high-output solutions in order to generate results of scientific value faster and more reliable (Fig. 1).

Fig. 1: Chemspeed´s vision on High-Output Product Development

Prominent progress got implemented in automated materials synthesis and formulation. For example Chemspeed´s fully automated formulation workstation FORMAX provides faster & better investigation of both the raw material and the process space. Essential for unrestricted automated formulation research is overhead gravimetric dispensing of liquids, viscous liquids, pastes, and waxes while stirring, scraping, heating, refluxing, and cooling.

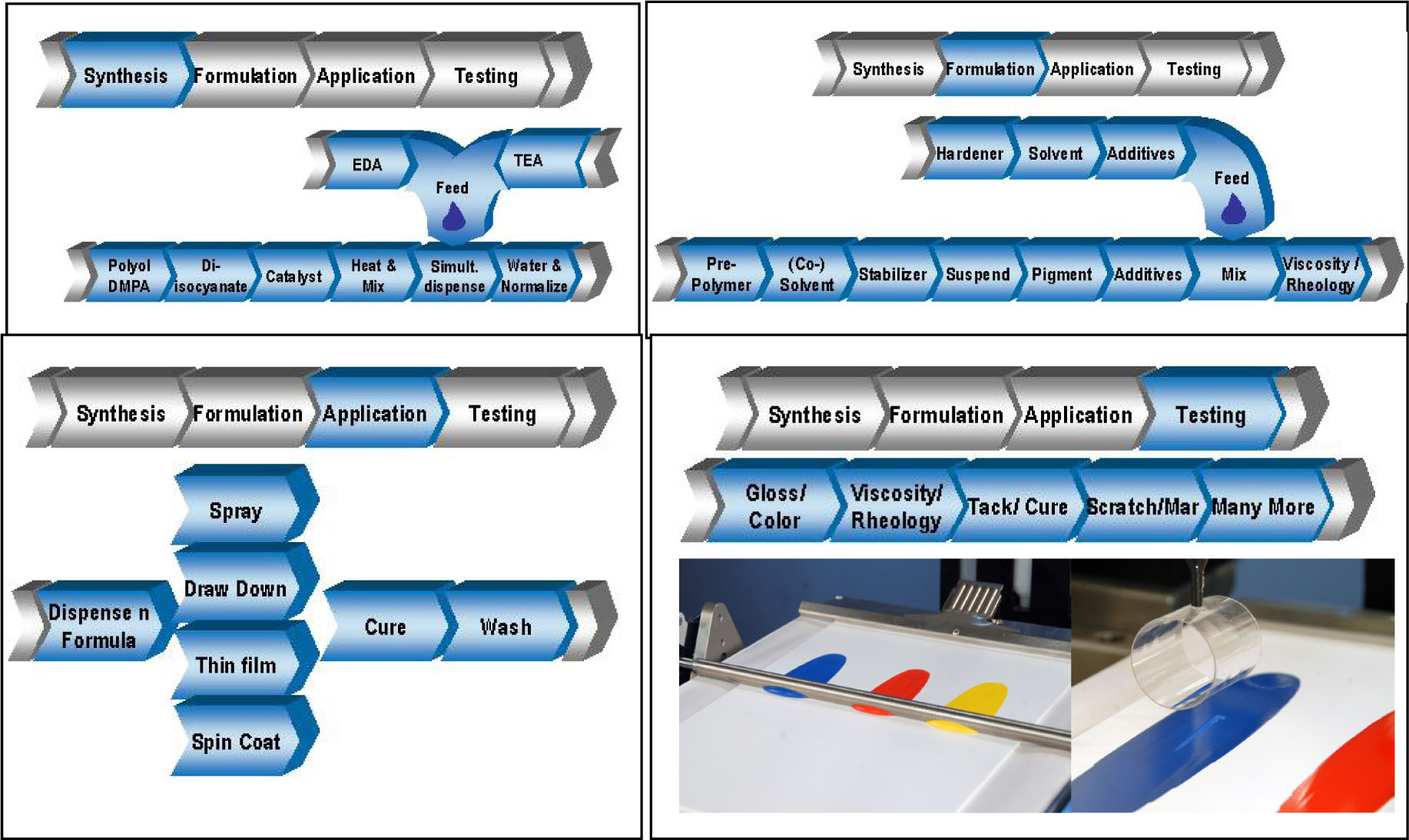

This presentation will share a selection of case studies in paints & coatings research. Case studies from polymer synthesis, paint formulation, paint application, and testing (Fig. 2 & Fig. 3).

Fig. 2: Master workflow in paints & coatings research

Fig. 3: Detailed workflows in paints & coatings research

Indu Babu

Eindhoven University of Technology, Departement of Chemical Engineering and Chemitry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands

Title lecture

Highly flexible 0-3 PZT/PDMS composite films

Authors

I. Babu and G. de With

Abstract

Highly flexible piezoelectric PZT/PDMS composites of 0-3 connectivity were fabricated by dispersing the piezo-ceramic lead zirconate titanate (PZT) in a poly dimethyl siloxane (PDMS) matrix. Solution casting technique is utilized for the fabrication procedure. The dielectric constant (εr) and the electrical conductivities of the composites were measured as a function of frequency range. The piezoelectric charge constant (d33) of these composites was measured on a d33 meter at a fixed frequency at 110 Hz. The mechanical properties of the composites were tested by dynamic mechanical analysis (DMA) in order to evaluate the flexibility of these composites.

Prof.Dr. Massimiliano Barletta

Università degli Studi di Roma Tor Vergata, Dipartimento di Ingegneria Meccanica,Roma, Italy

Title lecture

Manufacture and characterization of free-standing epoxy-polyester films

Authors

M. Barletta and D. Bellisario

Abstract

The present investigation analyzes the deformation behavior under static and dynamic loading conditions of electrostatically sprayed epoxy-polyester powder coatings by local and uniaxial tests, trying to account for the separate contribution of the raw polymeric material alone and of the adhesion to the underlying metal substrate. First, thermo-rheological properties of the basic material were characterized. Secondly, free-standing films were manufactured by electrostatic spraying of the thermosetting powders onto stainless steel substrates pre-coated with an intermediate layer of silicon-based heat curable release coating. The resulting free standing-films were macroscopically characterized by uniaxial tests. Finally, local mechanical characterization of the epoxy-polyester films was carried out by micro-scale depth sensing scratch and indentation on coatings "free-standing" and "rigidly-adhering" onto the metal. The experimental findings show the different mechanical behavior of the coatings when deposited on untreated or pre-treated substrates as well as on intermediate layers of release coating, thus contributing to understand how much of the coating properties is ascribable to the material or to the interfacial adhesion between coating and substrate.

Denise Bellisario

Università degli Studi di Roma La Sapienza, Dipartimento di Meccanica ed Aeronautica, Roma, Italy

Title lecture

Effects of IR pre-curing conditions on wear resistance of metal flakes powder coatings

Authors

D. Bellisario and M. Barletta

Abstract

Hybrid IR/convective oven baking of high quality industrial powder coatings is one of the most attractive method to achieve significant economic and process time savings. The optimization of the IR pre-curing and the correlation between the effect of polymerization degree of the basecoat and the wear resistance of the whole coating system are investigated. In particular, an experimental study in which the degree of chemical conversion of the pigmented basecoat, the overall coating morphology and its thermal, mechanical and tribological properties are analyzed in the light of IR-radiation time and power, has been performed. Experimental results show that the intermediate range of curing time and IR power investigated leads to properly cured basecoats and subsequently to better morphological, mechanical and tribological behavior of the whole coating system. These results were also validated by comparison to the coatings cross-linked by the traditional two-step oven baking process. Finally, a first approximation model which correlates the degree of conversion of the polymeric material and the mechanical and tribological behavior of the coatings has also been built on.

Camille Carcouët

Eindhoven University of Technology, Department of Chemical Engineerig and Chemistry, Laboraroty of Materials and Interface Chemistry, Eindhoven, The Netherlands

Title lecture

Nature-inspired superhydrophobic surfaces from raspberry-like particles

Authors

C. Carcouët, A.C.C. Esteves, R.A.T.M. van Benthem, G. de With

Abstract

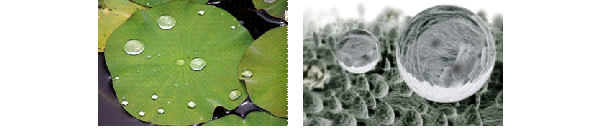

Superhydrophobic surfaces have attracted much interest in the last decades for both fundamental research and practical applications. The development of such surfaces is mostly driven by the promise of self-cleaning properties of these coatings [1].

Superhydrophobic and self-cleaning surfaces already exist widely in nature, such as butterfly wings, legs of a water strider or leaves of some plants. Amongst them, the most famous example of self-cleaning is of course the lotus leaf, symbol of purity in several Asian religions. Despite growing in muddy water, the leaves remain clean; when rainwater hits the leaves of the lotus plant, the droplets roll off the surface, washing off any contaminations and dust (Figure 1).

Figure 1: Lotus leaf with water droplets on top (left) and nanostructure of the surface of a leaf (right).

Previous studies revealed that self-cleaning property of lotus leaves originates from the combination of micrometer-scale hills and valleys and nanometer-scale waxy bumps, together with the reduced adhesion between surfaces and particles. Their surface is usually labeled as, hydrophobic. [2]. Generally, a surface is called superhydrophobic if it exhibits a water contact angle larger than 150° and a low sliding angle. The dual-size roughness combined with the proper chemistry appears to be essential to reach superhydrophobicity.

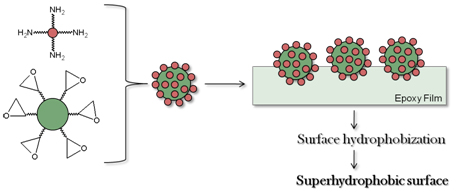

In a previous cooperation between DSM and TU/e, a nature-inspired approach, christened the "raspberry" approach, has been developed, leading to superhydrophobic surfaces [3]. In this method, the key to introduce well-controlled dual-size roughness involved the synthesis of raspberry-like inorganic silica particles. In a first step, large epoxy-modified silica particles (700 nm) were reacted with small amino-modified silica particles (70 nm). The surface with a dual-size hierarchical structure was then developed by depositing these raspberry-like particles on an epoxy based coating. Finally, a layer of PDMS was grafted on the top of the rough surface to render the film surface superhydrophobic (Figure 2) [4].

Figure 2: Preparation of superhydrophobic films based on raspberry-like particles [3].

However, due to the large particle size, this superhydrophobic coating is not optically transparent. The "raspberry" approach typically uses particle sizes in the order of the wavelength of visible light and therefore scattering occurs. But for many applications, in particular for displays, transparency is of the utmost importance.

Hence, the first aim of this project is to develop a structure with sufficient hydrophobicity as well as transparency directly on a glass surface during tempering of the glass. To this end, it is necessary to realize a dual-sized surface topology as obtained with the raspberry approach on a much smaller scale, i.e. down to 10/80 nanometer scale. Thereafter, the aim is to further improve the scratch-resistance of the material, demonstrated in a previous work [4].

Herein, we present the successful synthesis of inorganic silica nanoparticles within the targeted range. The modification of the particles was investigated, leading to the amino- and epoxy-functionalization of the silica particles. The synthesis of the raspberry-like nanoparticles was further investigated, and the first superhydrophobic transparent coatings were prepared. The synthesized particles were characterized by DLS and IR Spectroscopy and their morphology was evaluated by SEM and TEM.

References

- Bhushan, B.; Jung, Y.C.; Koch, K., 25, 3240, (2009)

- Neinhuis, C.; Barthlott, W., Annals of Botany, 79, 667, (1997)

- Ming, W.; Wu, D.; van Benthem, R.; de With, G., Nano Lett., 5, 2298, (2005?

- Wu, Di - Nature-inspired superlyophobic surfaces - Eindhoven University of Technology, (2007)

Belén Díaz Benito

Materials Science and Engineering Department, Universidad Carlos III de Madrid, Madrid, Spain

Title lecture

Deposition of g-methacryloxypropyltrimethoxysilane coatings on 6063 aluminium alloy treated with atmospheric plasma: characterization by FTIR and contact angle measurements

Authors

Belén Díaz Benito, Francisco Velasco

Abstract

This study is based in the use of γ-methacryloxypropyltrimethoxysilane (MPS) as an environmentally friendly solution to remove chromium (VI) from the pre-treatment of lacquered aluminium. In this research, the hydrolysis process of MPS at 1% in aqueous solution by means of Fourier transform infrared spectroscopy (FTIR) was studied, determining the hydrolysis time for which a greater number of Si-OH groups has been obtained. Different times at pH 4 were studied to establish the most optimal application conditions for bonding to the substrate. It was possible to observe how the bands corresponding to the Si–O–C groups present in the pure silane spectrum continued to appear after short periods of hydrolysis. However these bands practically disappeared upon increasing of this hydrolysis time, with other new ones appearing corresponding to the Si–OH vibration.

The silanization of 6063 aluminium alloy samples was also carried out. Analysis of the silane layers by means of FTIR indicated that the immersion time may be important according to the hydrolysis conditions, and it also allowed optimizing the drying time. Silane distribution is not uniform generating defects in lacquered samples. Different ways of deposition have been studied. The commonly used way to silanize, immersion of the bare sample in the silane solution, is compared to the treatment of the bare samples with atmospheric plasma, which improve samples surface energy and it is expected to improve the distribution of the silane. The effect of the plasma in the bare samples was studied by contact angle measurements.

Dr Christine Dumas

Groupe des Procédés de Séparation (GPS), IPHC-DSA, UMR CNRS 7178, Université de Strasbourg, Strasbourg Cedex 2, France

Title lecture

Hydrogen permeation as an indicator to evaluate the porous/dense character of multiple nickel autocatalytic deposits

Authors

Jamal AMER, Christine DUMAS, Barbara ERNST

Abstract

In order to increase the knowledge of the coating process and to predict the quality of nickel layers versus the operating conditions, the growth of nickel deposits with high purity (99.3%) on ceramic supports, different in chemical nature (Al2O3, ZrO2) and porosity (pore diameter from 5nm to 0.8mm) was investigated after several treatments in terms of texture by SEM observations and adherence (depth of penetration of the metal).

A preliminary study of the plating bath containing hydrazine as reducing agent by UV-visible spectrometry coupled with the FT-IR spectroscopy measurements allowing to identify the metastable complex, reduced during the electroless plating treatment, as the Ni-hydrazine complex ([Ni(N2H4)n(CH3COO)2 with n=2,3), pointing out the double role of hydrazine: complexing and reducing.

Obtaining nickel metal films in a reproducible manner with a thickness ranging from 2 mm to 40 mm depending on the number of treatments allows to conclude that the pore size of the support is a key parameter on the Ni film thickness and its adhesion on the support, induced by the diffusion or not of nickel particles (35 nm) through the support and by the autocatalytic activity of the nickel occluded in the pores. The texture of the deposits was star-shaped and seems to be dense after a thermal treatment at 900 °C under H2/He. Differentiating finely the parameter of porosity or the presence of defects on each layer of very low specific surface area becomes a real challenge.

The selective permeation of hydrogen (kinetic diameter: 0.289 nm) towards molecules like nitrogen could be a technology of choice to detect the nanometric pores/defects by analyzing the mode of transport (Knudsen, surface diffusion, activated Knudsen). The results showed that more than the thickness and texture of the nickel layer, the efficient covering of the external porosity of the support by the metal could have a beneficial impact on the selectivity of these materials working in some cases as molecular sieve.

Roland Emmerich

Robert Bosch GmbH, Packaging Technology, Bosch Lab Systems, Waiblingen, Germany

Title lecture

Experience with Automated Development and Spray Application of Coatings

Authors

Roland Emmerich, Tobias Burk, Thomas Brinz. Robert Bosch GmbH, Waiblingen, Germany

Jürgen Ortmeier, Karl Wörwag Lack- und Farbenfabrik GmbH & Co. KG, Stuttgart, Germany

Abstract

In the pharmaceutical industry or for development of catalysts High Throughput Experimentation (HTE) has been used for more than 20 years. Meanwhile this technology has also found its way into other industries. Two years after the first implementation of an automated system for development of coating materials we are able to report about the benefits of this method.

The High Throughput system was developed with a number of goals in mind: shorter duration of development, increased effectiveness, decreased time-to-market, higher quality of experimental results, reduced sample and waste quantity, close-to-reality spray application. Our poster shows that these challenging goals could be fulfilled by utilizing modern formulation technologies, conventional robotics and a modified standard spray head.

Design of Experiment (DoE) was used for selecting the parameter space when developing a new recipe for a water-based clear coat. The automated system produced the individual formulations and applied them to test panels by spray coating. Characterisation was carried out off-line after automated flash-off and curing at elevated temperature. The influence of two different additives, two solvents and two binders on the coating properties such as DOI was investigated. A matrix of over 200 samples was tested within a few days. We found that there is a non-linear relationship between the effects of the two additives. In a second set of experiments the effect of varying the rheology module and its concentration in an existing formulation was investigated.

The results of the experiments clearly showed that systematic optimisation of a coating can be carried out much faster and easier by utilizing DoE and lab automation. Interaction between the components of a formulation is not always linear. Automating the lab work flow can help to find such non-linear behaviours and enable the scientist to use this knowledge when developing new formulations.

Dr. Bart Erich

TNO Built environment and Geosciences, Delft, The Netherlands

Eindhoven University of Technology, Department of Physics, Group Transport in Permeable Media, Eindhoven, The Netherlands

Title lecture

Water transport through coatings into wood

Authors

S.J.F. Erich, P.A. v. Meel, H.P. Huinink, O.C.G. Adan, J. de Jong

Abstract

Coatings are applied on wood mainly for protective and aesthetic reasons. A coating should reduce and slow down moisture uptake by wood and thereby its degradation. The goal of the presented research was to investigate the influence of different coatings (waterborne acrylic and solventborne alkyd) on the moisture transport into wood (meranti, spruce and pine) by Magnetic Resonance Imaging. Moisture transport through coated wood is largely determined by the interaction between coating and the wood. Many factors determine the final moisture barrier properties, such as the type of binder, the viscosity and the degree of pigmentation of the coating as well as structure of the wood surface. Consequently, studying the barrier properties of coatings applied on different wood samples reveals the parameters that determine the barrier properties. In this study, the influence of several coatings on the moisture transport in wood was studied for meranti, spruce, and pine. These wood types were chosen because they largely differ with respect to their structure in general and the presence of porous channels in contact with the wood surface in particular. MRI monitors the moisture content in the wood non-destructively over time. In contrast to gravimetry, MRI measures the water absorption and desorption of coated and uncoated wood with high spatial and temporal resolution. In addition, water in lumina and cell walls can be distinguished with MRI relaxometry, which allows identifying the physical nature of the sorption processes in wood. A 4.7 T MRI scanner was used to measure the spatial moisture distribution during wetting and drying processes with a resolution of 33 μm, which made it possible to simultaneously visualize the moisture in the wood and the coating itself. It was shown that the sorption behavior of coated wood largely depends on the specific combination of wood and coating. The barrier properties of the waterborne acrylic and solventborne alkyd coating differed completely. The samples which were coated with the alkyd system showed almost no water uptake. The used acrylic paint did not reduce the water uptake in meranti, i.e. the water ingressed as fast in coated and uncoated meranti. For the pine the acrylic coating prevents water from entering the tracheids and resin canals. Further, a correlation is observed between the wetting and drying behavior of the wood-coating system. Additionally, results indicate that increased layer thickness (which was also investigated) might pose problems with respect to water retention.

Dr. Catarina Esteves

Eindhoven University of Technology, Departement of Chemical Engineering and Chemitry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands

Title lecture

Superhydrophobic self-replenishing coatings through the design of surface topology and chemistry

Authors

A.C.C. Esteves*, M.W.P. van de Put, G. de With

Abstract

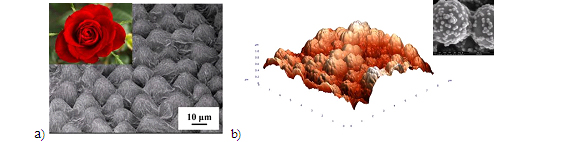

Nature has created materials with striking features, like the superhydrophobic rose petals or butterfly wings with iridescent colors1. In many cases this remarkable properties rely on the combination of a well-defined chemistry and surface topology (Figure 1).

Taking an inspiration from Nature, several functional coatings have been developed with advanced properties, such as self-cleaning, anti-fouling, stain resistant or water-repellency. In these coatings the combination of surface roughness and specific chemical composition is also the key for success.

Apart from a few exceptions2, most of the chemically synthesized superhydrophobic surfaces reported, are easily damaged (even by simple handling) resulting in the loss of: surface-structure, chemical functionalities and related chemical/physical properties. This irreversible damage reduces the materials service-life time and increases the maintenance efforts and costs. Hence, the investigation of robust structured-surfaces, which are able to withstand daily usage for a long period of time, is critical for the sustainable development of coatings with advanced properties, e.g. easy-to-clean/self-cleaning ability3. Since the damage of coatings can never be fully avoided, introducing self-repairing mechanisms which can (partially) recover the chemical/physical properties of the material can be one way to reduce it.

We are currently combining a self-replenishing polymer system4 and the incorporation of inorganic nanoparticles to design robust superhydrophobic self-replenishing coatings. The rough surfaces of these materials have low-surface-energy groups which can be reoriented towards new surfaces, created upon damage. Herein, we report our developments on the synthesis and characterisation of superhydrophobic coatings with a single and double-scale surface roughness and low-surface-energy groups segregated at the air/coating interface, which contain simultaneously a self-replenishing polymer system.

Figure 1: a) SEM image of red rose´s petals; AFM and SEM (inset) image of one of the self-replenishing coatings prepared with dual-scale roughness.

References

- Xia, F.; Jiang, L. Adv. Mater. 2008, 20, 2842-2858.

- Ming, W.; Wu, D.; van Benthem, R.; de With, G. Nano Letters 2005, 5, 2298-2301.

- Solga, A.; Cerman, Z.; Striffler, B. F.; Spaeth, M.; Barthlott, W. Bioinspir. Biomim. 2007, 2, S126-S134.

- Dikic, T.; Ming, W.; Thüne, P.; Tian, M.; Van Benthem, R.; de With, G. Polymer Preprints, Amer. Chem. Soc. 2008, 49, 972-973.

Dr. M. Farshchi-Tabrizi

Physics Department, Bu- Ali Sina University, Hamedan-Iran /

Max-Plank Institute for polymer Research, Maniz-Germany

Title lecture

Surface modification of chitosan membrane treated by N2 and Ar Plasma

Authors

B. Jaleh, M. Farshchi-Tabrizi, P. Wanichapichart, N.gholamia, R.Mashayekhid,A. Pourakbar Saffare

Abstract

Dense chitosan membrane were prepared and investigated for surface modification using argon and nitrogen plasma produced at low pressures with Radio frequency (RF) at power ranging from10-50 W. RF plasma offers a unique route for surface modification of polymers. The influence of the plasma treatment conditions on the basic properties of the membranes, namely pore size and flow rate has been studied. The action of plasma on porous membranes results in polymer ablation leading to the increase of the mean pore diameter confirmed by increasing water flux for plasma treated pp membrane and decreasing constant dielectric. In determining the flux, the hydrophilicity of the surface played a role as important as that of the micropore size. Changes of membrane characteristics after the N2 and Ar plasma treatment were examined. The contact angle with water decreases and wettabilities have increases with the increase of plasma treatment time.

Emilie Faure

Center for Education and Research on Macromolecules (CERM), University of Liège, BelgiumK

Title Lecture

A green and refillable antibacterial coating for stainless steel

Authors

Emilie Faure, Aurélia Charlot, Valérie Sciannaméa, Sandrine Lenoir, Robert Jérôme, Christine Jérôme, Cécile Van De Weerdt, Joseph Martial, Catherine Archambeau, Nicolas Willet, Anne-Sophie Duwez, and Christophe Detrembleur

Abstract

Because of its resistance to corrosion and chemicals, relevant mechanical and esthetical properties, stainless steel (SS) is widely used in the daily life (food industry, household appliances, surgery …). However, SS is unable to prevent bacteria from adhering, proliferating and forming a resistant biofilm when ageing. Therefore, surface modification is needed for providing durable antibacterial properties.

We report here on an all-in-one approach to prepare refillable antimicrobial films [1] using the layer-by-layer deposition of polyelectrolytes. Specifically designed biocidal multilayered polyelectrolyte films that bear 3,4-dihydroxyphenylalanine (DOPA), known as a promoter of adhesion to inorganic surfaces, were deposited onto SS. DOPA was incorporated in the polycationic chains by radical copolymerisation of N-methacrylated DOPA with the quaternary ammonium salt of 2-(dimethylamino)ethyl methacrylate (DMAEMA+). In order to boost the antibacterial activity of the polycationic layer, AgNO3 was added to the aqueous solution of P(DOPA)-co-P(DMAEMA+), which resulted in the in-situ formation of silver based nanoparticles, sources of biocial Ag+. The layer-by-layer deposition of aqueous P(DOPA)-co-P(DMAEMA+/AgCl/Ag0 suspension and aqueous solution of poly(styrene sulfonate) provides high antibacterial activity against Gram-negative E. Coli bacteria. Moreover, after silver depletion, films retain some antimicrobial activity, thanks to ammonium groups of the copolymer. We also show that the antibacterial activity of the films can then be easily re-boosted.[1]

Acknowlegments

The research was partly supported by BELSPO in the frame of IUAP VI/27 and Région Wallonne, ArcelorMittal and ULg through the PPP program BIOCOAT. C.D. is “Maître de Recherche” of the F.N.R.S. (Belgium), and thanks the F.R.S.-F.N.R.S. for financial support.

References

[1] A. Charlot, V. Sciannamea, S. Lenoir, E. Faure, R. Jerome, C. Jerome, C. Van De Weerdt, J. Martial, C. Archambeau, N. Willet, A.-S. Duwez, C.-A. Fustin, C. Detrembleur, Journal of Materials Chemistry 19, 4117-4125(2009)

Michele Fedel

Department of Materials Engineering and Industrial Technologies, University of Trento, Trento, Italy

Title Lecture

Silicon alkoxides sol-gel hybrid coatings containing clay nanoparticles for corrosion protection of galvanized steel

Authors

M. Fedel, F. Deflorian, S.Rossi,

Abstract

Silane sol-gel coatings are widely used as adhesion promoters between inorganic substrate, such as metals, and an organic coating. The aim of these pretreatments is to enhance the corrosion protection performances of the organic coating improving the adhesion with the substrate and acting as a barrier against water and oxygen diffusion. It is a matter of fact that the silane sol-gel coatings do not provide an active protection against corrosion processes, although they ensure a partial inhibition of the cathodic reactions occurring on the metal surface. The barrier properties of the silane sol-gel coatings can be further enhanced adding inorganic nanoparticles into the hybrid film. In principle, clay nanoparticles can be embedded inside a silane sol-gel solution due to the proved chemical interaction between the clay and the silicon alkoxides molecules. In this study sodium montmorillonite nanoparticles were used as nanofiller for the development of sol-gel hybrid coatings with improved corrosion protection properties. The sol-gel matrix consists in the combination of three different silicon alkoxides molecules, such as γGlycidil-oxypropil-triethoxy-silane (γGPS), Tetraethoxy-silane (TEOS) and Methyl-triethoxy-silane (MTES). Different amounts of the nanofiller (200 to 2000ppm of montmorillonite particles) were dispersed in water and mixed with the silicon alkoxide molecules. Hot dip galvanized steel sheets were coated with the silane solution containing the nanoparticles. After a heat treatment the film the properties of the sol-gel coatings containing different amounts of nanofillers were investigated. The effect of the montmorillonite nanoparticles on the barrier properties of the sol-gel coatings was investigated by means of electrochemical impedance spectroscopy (EIS) and polarization measurement. The experimental evidences highlighted the amount of nanofillers to obtain the highest corrosion protection performances. The films were also characterized using both scanning electron microscope (SEM) and transmission electron microscope (TEM). Electron diffraction patterns of the sol-gel films were also collected to determine the effect of the montmorillonite nanoparticles on the structure of the sol-gel films. The microscopy analysis seems to indicate that the nanofillers promote the formation of crystalline silica domains into the sol-gel matrix. Some attempts to correlate this experimental evidence with the different barrier properties of the produced sol-gel coatings were performed.

Dr. Adolphe Foyet

Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands

Title Lecture

Barrier properties of a chromate free primer on Al-2024

Authors

A. Foyet, T. H. Wu, C. Hänsch, A. Kodentsov, L. G. J. van der Ven, G. de With, R. A. T. M. van Benthem

Abstract

The Al-2024 alloy widely used in Aircraft Company is a heterogeneous material containing galvanic couples between the intermetallic inclusions. Intermetallic compounds increase the strength but decrease the corrosion resistance of this alloy. The objective of paint and coatings companies is to provide efficient and environmental friendly coatings to protect this alloy against corrosion.

The aim of this work is to determine the diffusion coefficient, the permeability of water and the corrosion performance of a chromate free coating applied on Al-2024. The capacitance of two coatings of similar composition which are applied respectively on Al-2024 and platinum substrates is compared. The impedance of Al-2024 substrate coated with this primer was recorded after several hours of immersion in a 0.5 M NaCl aqueous solution.

Water and oxygen molecules diffuse into the coating. The water volume fraction in the coating increases with the immersion time and reaches a plateau after saturation. No saturation plateau was found in the case of coating applied on Al-2024 since the interfacial oxide layer also absorbs water. The solubility of water can be determined only when the coating is applied on inert substrate such as platinum. The permeability of water was estimate to be 7.6 x 10-12 kg m-1s-1. After several days of immersion in sodium chloride, the impedance magnitude at low frequency remains higher than 108 Ohm.cm2. The coating maintains its barrier properties, no delamination was observed. The good performance is probably due to the combination of coating (with fillers particles) and the columnar oxide layer on Al-2024, both of which act as a passive film.

Santiago Garcia Espallargas

Delft University of Technology, Department of Aerospace Materials and Manufacturing, Kluyverweg 1, 2629 HS, Delft, The Netherlands

Title Lecture

Self-healing anticorrosive organic coating based on the release of a reactive Silyl Ester

Authors

S.J. Garcia, H.R. Fischer, P.A. White, J. Mardel, A.E. Hughes, J.M.C. Mol

Abstract

The easiest and mostly applied method to protect and to reduce corrosion rates of metals is the use of organic coatings which offer protection by active pigment release and passive barrier mechanisms. However, when these systems suffer any kind of damage the passive protection is no longer there and the metal substrate is directly exposed to the corrosive environment. Under these conditions, corrosion inhibitors, of which the most used and efficient ones are chromate-based pigments, are leached out from the coating and act at the metallic substrate. This mechanism is known as self-healing (SH) mechanism by inhibitor release. Intrinsic to this approach is that the pigment in the coating is released without control until there is no more pigment left in the coating. This leaves a depletion zone in the coating that does not allow further protection.

During the last decade, a different active SH mechanism based on the sealing of the crack-damage has been described and implemented to anticorrosive organic coatings. This second approach proposes the recovery of the barrier protection by the reaction of chemical species that are released from the coating or by the use of expandable phases which will close the crack. One of the problems of this approach is that the sealing of the crack can entrap water and corrosive agents between the newly created barrier system and the metal thus impelling undercoating corrosion processes.

A possible solution to these problems would be the use of a system that protects the metallic surface by reaction with water at the metallic surface creating a passive layer on top of the metal. In this work a new organic-based healing agent based on a silyl ester is presented and its synthesis and performance is described. The silyl ester was first tested as a repairing agent (assisted healing) and secondly encapsulated and incorporated into an organic matrix to study the autonomic self-healing properties of the complete system. A new high-throughput technique for healing agents´ evaluation named multiwell was employed to determine the minimum amount of agent to heal a crack. In order to evaluate the healing ability of the silyl ester, Electrochemical Impedance Spectroscopy (EIS) is used and identified to be a key technique for the development and performance evaluation of self-healing anticorrosive organic coatings.

Argyrios Georgiadis

University of Surrey, Department of Physics, Faculty of Engineering and Physical Sciences, Guildford, UK

Title Lecture

A new method for making hard, No-VOC waterborne coatings

Authors

A.Georgiadis, J.L. Keddie, M. Murray, J. Jennings, S. Emmett, P. Beharrell

Abstract

In the coatings industry, there is a need for hard and clear waterborne coatings. A polymer with a high glass transition temperature, Tg, must be used to make a hard polymer coating. When a latex film made from a hard polymer dries at room temperature, it is subject to cracking [1]. One method to avoid cracking is to add plasticizers to aid film formation, but the use of this type of additive is coming under scrutiny for environmental reasons. Another method is to heat the latex film to a temperature well above the Tg of the polymer. In the past, convection ovens have been used for heating, but this process consumes a relatively high amount of energy. We have developed an alternative technique for making hard latex films in which latex films are heated above the polymer´s Tg through radiative heating from an infrared (IR) lamp [2]. This technique has the advantages of not using VOCs and having low energy consumption.

This poster will demonstrate the film formation of an acrylic copolymer with a Tg of 38 °C using IR radiation. The sintering of the latex particles as a function of time of exposure under IR radiation has been studied with the aid of atomic force microscopy [3]. The flattening of the particles at the film surface, which is indicative of sintering, is faster under IR radiation than when the films are heated in a convection oven at 60 °C. Furthermore, the hardness of the IR-sintered films has been measured with indentation experiments [4] and found to be comparable to films formed in a convection oven.

Poly(3,4-ethylenedioxythiophene)/poly(styrene sulfonate) (PEDOT:PSS), which is strongly IR absorbing, was added at low concentrations, and its effects on the sintering process were studied. The addition of PEDOT:PSS results in a higher temperature increase under IR exposure. Also, the sintering of the particles is faster under IR radiation for latex containing small quantities of PEDOT:PSS, compared to the plain acrylic latex.

References

- K. B. Singh and M. S. Tirumkudulu (2007) Physical Review Letters, 98, 218302.

- J.L. Keddie and A. Georgiadis (2009) British Patent application GB0903297.0.

- M. Cynthia Goh, D. Juhue, On Man Leung, Y. Wang, and M.A. Winnik (1993) Langmuir, 9, 1319-1322

- K.W. Xu, G. L. Hou, B.C. Hendrix, J.W. He, Y. Sun, S. Zheng, A. Bloyce, T. Bell (1998) Journal of Materials Research, 13, 3519-3526

Dr.ir. Nathalie De Geyter

Department of Applied Physics Faculty of Engineering - Ghent University (UGent), Belgium

Title lecture

Plasma-assisted deposition of polymethyl methacrylate onto TiO2 substrates

Authors

N. De Geyter, R. Morent, M. Frère-Trentesaux, P. Dubruel, C. Leys1 and E. Payen

Abstract

Plasma polymerization is a unique technique to fabricate thin polymer films from a wide variety of organic and organometallic precursors. Plasma polymerized films are pinhole-free and highly cross-linked and therefore insoluble, thermally stable, chemically inert and mechanically tough. Furthermore, such films are often highly adherent to a variety of substrates including conventional polymer, glass and metal surfaces. Due to these excellent characteristics, plasma-polymerized films have been used in a wide variety of applications including barrier coatings, protective coatings, selective permeation membranes and dielectric layers in microelectronics. Besides these well-known examples, state-of-the-art applications are continuously being developed, especially in the biomedical domain.

Generally, a large part of research related to plasma-assisted thin film deposition has involved low pressure non-thermal plasma technologies. Although vacuum treatment processes afford good control over gas chemistry and provide the possibility of using high energetic species (in the range of several eV to hundreds of eV) in the deposition process, atmospheric pressure processing techniques are offering specific advantages, such as the elimination of expensive vacuum equipment, easier handling of the samples and scalability for industrial on-line processing. Therefore, in recent years, a lot of effort has been put into the development of non-thermal plasma reactors for thin film deposition working at or near atmospheric pressure.

This paper will focus on the formation of coatings in an atmospheric pressure dielectric barrier discharge (DBD) using methyl methacrylate (MMA) as gaseous precursor. Plasma polymerized films will be deposited onto TiO2 samples, which is a common material used for artificial hips. Depositing a polymethyl methacrylate (PMMA)-like coating onto TiO2 can improve the fixation of artificial hips, since the bone cement used to fixate the hip into the human body normally consists of MMA or PMMA. In this work, the chemical and physical properties of the obtained PMMA-like coatings will be discussed in detail using Fourier transform infrared spectroscopy (FTIR), X-ray photoelectron spectroscopy (XPS) and atomic force microscopy (AFM).

Prof.Dr. Mahmood Ghoranneviss

Islamic azad University, Plasma Physics Research Center, Science and Research Branch, Tehran, Iran

Title lecture

Investigation on Dye ability and Antibacterial activity of nano- Layer Platinum Coated Polyester fabric Using DC Magnetron Sputtering

Authors

M.Ghoranneviss, S.Shahidi, J.Wiener, H.Shahbakhti, A.Hatmi

Abstract

Low temperature plasma treatment has been conducted in textile industry and has some success in the dyeing and finishing processes. PET fibers have been increasingly used in textile industries for a variety of applications ranging from filtration, composites, and tissue engineering and electronic textiles. The surface properties of these polymer fibers are of importance in various applications. The surface properties of PET fibers can be modified by different techniques. The affinity of Polyester fibers to natural dyes is too weak, so many research have done to improve the dyeability of this fiber. In this research work, one side of PET fabrics was coated by Platinum using DC magnetron sputtering. The textile properties of Pt-coated polyester fabrics were evaluated by different standard testing methods in terms of both physical and chemical performances. The dye ability of coated and uncoated samples to different natural and synthetic dyes was evaluated. The antibacterial counting test was used for determination of antibacterial efficiency of both treated and untreated samples, and durability of antibacterial properties was compared. The results show that, the existence of platinum nanolayer on the surface of PET fabrics causes improve the dyeability of fabrics. However, this improvement for natural dyes is more significant. Also the antibacterial activity of natural dyed samples is notable.

Ismail Dogan Gunbas

Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Polymer Chemistry, Eindhoven, The Netherlands

Title Lecture

Maleic Anhydride Based Copolymer Dispersions for Surface Modification of Polar Substrates

Autors

I.D. Gunbas, M. Wouters, R.A.T.M. van Benthem, C.E. Koning

Abstract

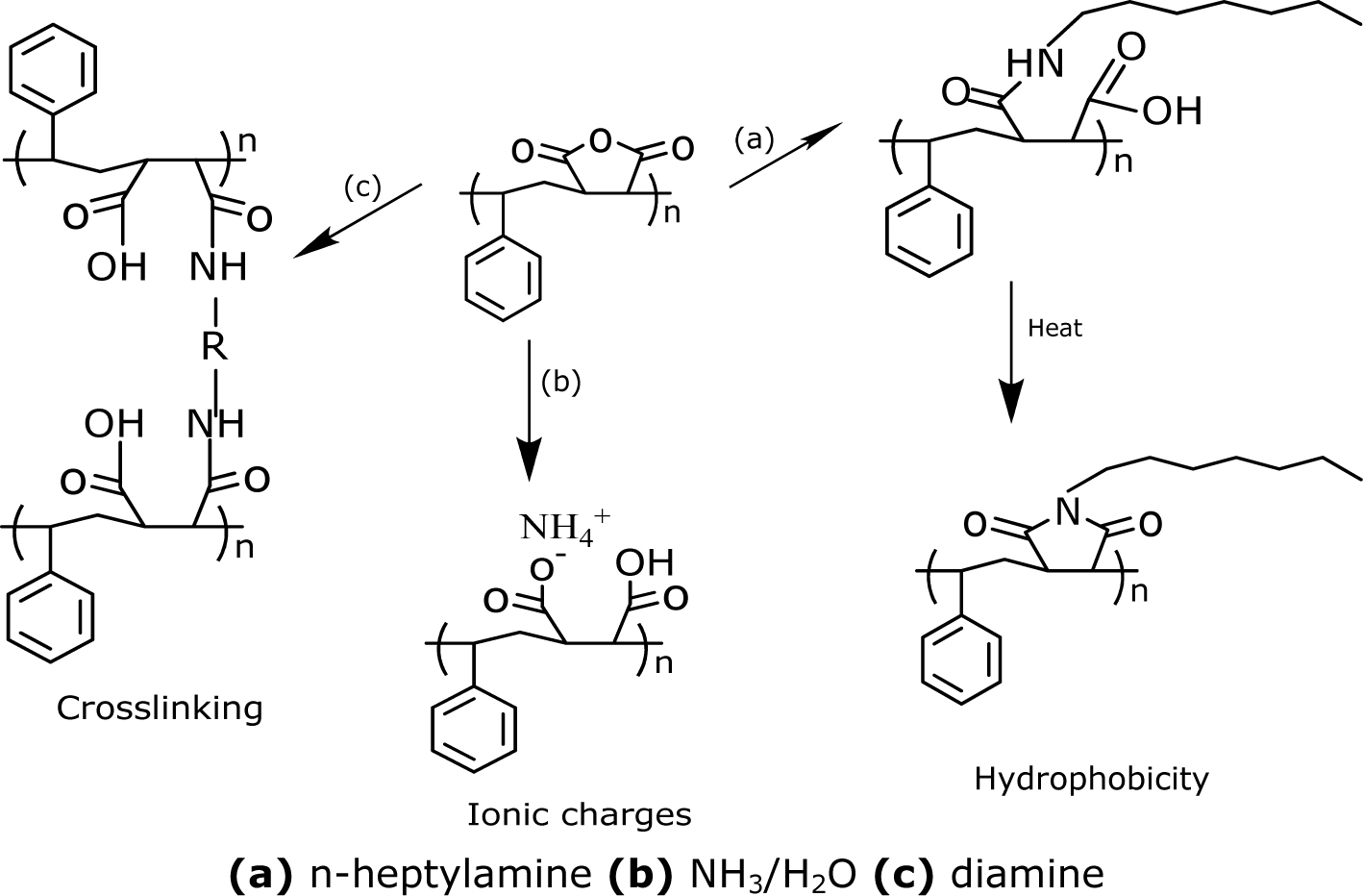

Chemical modifications of polymer surfaces can be applied to control adhesion, wettability, and biocompatibility as important surface properties of polymers that are of interest for a variety of applications. Flame treatment, corona discharge treatment, plasma modification, and surface graft polymerization are the practical approaches to polymer surface modification. Unfortunately, these techniques do not result in chemically well defined surfaces which in view of their demanding properties should be carefully designed and prepared. Our approach is that surface functionalities are introduced by a modification of polymer surfaces with water-based, alternating maleic anhydride copolymers, chemically modified with primary amines. Electrostatic stabilization of styrene maleic anhydride (PSMA) based particles can be obtained by partial ammonolysis of the anhydride groups with ammonia. The remaining anhydride groups can be used for crosslinking with diamines [1-3], as is schematically represented in Scheme 1, and/or for interaction with the polar polymer substrate.

Scheme 1. Schematic representation of the different possible reactions with

cyclic anhydride units in the PSMA polymer

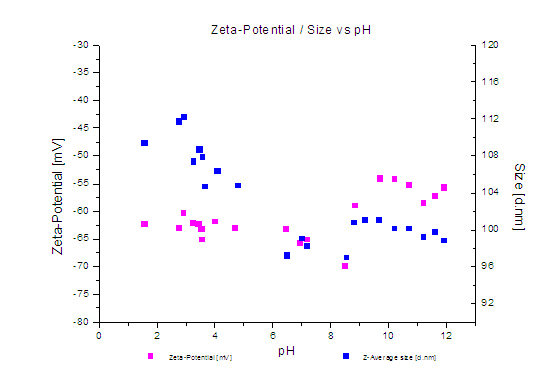

In this work, we report the preparation of surfactant-free artificial latexes on the basis of PSMA copolymer which was then modified using n-heptylamine and mono amino functional polydimethyl siloxane (PDMS-NH2). Self-emulsifying latexes with an average particle diameter of 150-190 nm and a zeta-potential of -65 mV have been successfully obtained from modified anhydride-containing polymers with various Tgs. It was found that the latexes are stable in the pH range of 2-9. Furthermore, the film formation of these latexes was studied; for the differently modified copolymer latexes, curing at temperatures above the Tg of the respective copolymers led to homogeneous film formation. Different latexes were coated on aluminum substrate. The wetting of the substrates could be optimized by etching the metal substrate. An alkaline pretreatment improved the adhesion with the polymer films for aluminum substrates. For future coating applications, these systems based on surfactant-free latexes have displayed promising properties.

References

- W.J. Soer, W. Ming, B. Klumperman, C.E. Koning, R.A.T.M. van Benthem, Polymer 47,2006, 7621-7627.

- B. Schlarb, M. Gyopar Rau, S. Haremza, Progress in Organic Coatings 26 1995;207-215.

- D.C. Blackley, H.F. Mark, N.M. Bikales, C.G. Overberger, G. Menges and J.I. Kroschwitz, Encyclopedia of Polymer Science and Engineering, Vol. 8, Wiley, New York 1987;pp. 66.

Dr. Claudia Haensch

Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands

Title Lecture

Screening of different epoxide/ amine combinations for the preparation of coating materials onto aluminum alloy 2024 substrates

Autors

C. Haensch, T. H. Wu, A. Foyet, A. Kodentsov, L.G.J. van der Ven, R.A.T.M. van Benthem, G. de With

Abstract

Aluminum alloy 2024 represents a high strength aluminum screw machine stock alloy, [1,2] which is known for its optimal weight to strength ratio.This makes the alloy an ideal candidate for applications requiring high strength, such as aircraft fittings and structures, computer parts, gears, shafts, hinge pins, valve blocks and valve parts, bolts, nuts, [1]

fasteners, truck parts and brake components.However, it contains also many different intermetallic inclusions. Therefore, this alloy is one of the most susceptible to localized [3] corrosion due to segregation of intermetallic particles at the grain boundaries. One possibility to still take advantage of the mechanical properties is to cover the substrate [2] with a layer of an organic material, which works as a protection layer. An interesting candidate for coating the aluminum alloy is a polymer network consisting of epoxide and amine due to their low water permeation coefficient and their strong adhesion to the substrate. However, the permeability of these epoxy/ amine coatings is strongly depending on the mixing ratio, the curing conditions and the application of the material onto the substrate.

The aim of the presented study is to design extremely resistant interphases between the Al alloys 2024 and the organic coating as well as to control of the mobility of water, hydrate ions and to improve the long-term stability of the polymer on the aluminum alloy.

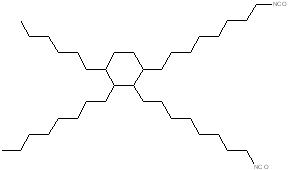

Therefore, a screening of different combinations of epoxides and amines is presented to study the properties of these coatings. A selection of two epoxides and four different amines is shown to enlarge the variety of different combinations. The polymer network is varied concerning hydrophobic/ hydrophilic properties, different crosslink-densities and the influence of aromatic vs. aliphatic moieties. Moreover, various curing conditions were applied to optimize the coatings. Additionally, the properties of these coatings are analyzed by differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA).

References

- http://www.alcoa.com/gcfp/catalog/pdf/alcoa_alloy_2024.pdf.

- A. Foyet, T.H.Wu, A. Kodentsov, L. van der Ven, G. deWith, R. van Benthem, Progress in Organic Coatings 2009, 65, 257-262.

- S.V. Lamaka, M.L. Zheludkevich, K.A. Yasakau, M.F. Montermor, M.G.S. Ferreira, Electrochim. Acta 2007, 52, 7231.

Dr. Mijeong Han

Advanced Materials Division Korea Research Institute of Chemical Technology, Yuseong-gu, Daejeon, South Korea

Title Lecture

Corrosion and wear resistance of multi-functional organic-inorganic hybrid coatings

Autors

Mijeong Han, Ji Yeon Seo, and Jiyoung Mang

Abstract

Organic-inorganic hybrid coatings containing both corrosion and wear resistance were prepared via each photo-curing and sol-gel process. Photo-curable formulations were prepared by using functional acrylates which have anti-corrosion groups and organically modified silica nanoparticles with acrylate for the better dispersion. Modified silica was added to methylene chloride and the solution was ultrasonificated. At this point, functional acrylate monomer was added and it was possible to prepare each coating solution containing tetramethyl tetra(ethoxyacrylate)cyclo tetrasiloxane(D4A) and photo initiator. Coating solution was dip-coated on iron plate and photo-curing was conducted with mercury lamp (80W/cm) for 5min. The corrosion protection properties of hybrid coatings on iron were studied by salt spray chamber test and electrochemical impedance spectroscopy (EIS), and wear resistance was measured by pencil hardness test. The corrosion and wear resistance of coating containing functional acrylate and D4A were superior to those of coatings with conventional acrylates. For thermal curing formulations via sol-gel process, sol-gel precursors containing anti-corrosion properties were synthesized by sequential Michael addition of methylaminoethanol to 1,4-benzoquinone, followed by the reaction with 3-isocyanatopropyltriethoxysilane. Epoxy was modified by 3-isocyanatopropyltriethoxysilane and the completion of the reaction was confirmed by the disappearance of NCO group in FT-IR. Sol-gel precursors, modified epoxy, HCl, H2.O, and diaminodiphenylmethane in tetrahydrofuran were stirred at room temperature for 1h and the solvent was removed under the reduced pressure. The resulting mixture was coated on iron substrates by dip-coating and heated to 80 ℃ for 12h and 160 ℃ 12h. The coatings on substrates were clean and transparent and showed very high pencil hardness up to 8H. The anti-corrosion properties of hybrid coatings were studied by salt spray chamber test and EIS. It was observed that the hybrid coatings with sol-gel precursors containing anti-corrosion ability exhibited much better corrosion protection on iron than those without them. This could be explained by the good adhesion and high affinity of anti-corrosion functional group to iron surface. Effects of the weight ratio of acrylate monomer and sol-gel components on the corrosion properties of hybrid coatings will be further discussed.

Dr. Marc Herold

Bühler PARTEC GmbH, CTO Business Unit PARTEC- Bühler AG, Saarbrücken, Germany

Title lecture

Superior eco friendly waterborne coatings due to nanoparticle technology

Authors

Dr. M. Herold and Dr. K. Steingröver

Abstract

Eco-friendly waterborne paints and coatings already gained considerable interest and market shares compared to traditional solvent borne systems. This ongoing development is not only driven by stricter legislation but also due to the general increasing environmental awareness. Even on the rise, waterbornes have well known limitation in overall performance compared to classical solvent born systems preventing their general use in several field of application.

An innovative performance additive, potentially closing the gap in performance deficiency of waterborne paints and coatings, will be presented. The exceptionally effective additive is based on nanoparticle technology containing tailor-made nanoparticles which improve the overall coating performance due to direct resin interaction. We assume that the nanoparticles interfere in the drying process resulting in a polymer network of higher density. This effect closely depends on the high degree of dispersion as well as by the high surface area of the nanoscaled particles. In addition, due to the neglectable light scattering, the technology is widely applicable also in transparent clear coats.

The general chemomechanical process to produce nanoscaled dispersions of inorganic oxides from agglomerated nano powders will be present including the chemical surface modification reaction under well-defined mechanical stress conditions for customization of nanoparticles with respect to industrial formulation.

Paramount advantages in performance enhancement on water-based acrylic emulsion systems for wood and metal substrates by utilizing this new additive will be presented. It positively improves several coating properties at the same time without negative consequences on others. In particular the considerable improvements regarding MEK rub stability, drying time, blocking resistance and stability against humidity will be highlighted.

In conclusion a novel and innovative approach by making use of nanoscaled particles will be presented having the potential to alter the landscape of eco friendly waterborne coatings.

Eliana Ieva

Solvay Solexis, Spinetta Marengo, Italy

Title lecture

Dirt pickup resistant PVDF coatings for architectural applications

Authors

Eliana Ieva, Shiow Lin, Valery Kapeliouchko, Bradley Kent

Abstract

Polyvinylidene fluoride (PVDF) coatings have been successfully used as long-lasting architectural coating[1] thanks to their superior performances than other competitive coatings . Architectural coatings are subjected to prolonged weather exposure that leads to photo-oxidative aging, gloss reduction, color change, chalking, and film erosion. Coatings based on Hylar® 5000 PVDF have outstanding properties such as high weatherability, excellent resistance to chemicals and corrosive atmospheres, resistance to oxidative degradation, exceptional color and gloss retention and a low level of chalking over a service life of >40 years. Dirt pickup is the deposit of foreign matter consisting of dirt, soot or stain that darkens the surface of a coated panel after exterior exposure [2] . The dirt pickup phenomenon is a complex issue and is determined by many factors. Dirt pickup of an exterior paint affects its long term appearance and corrosion protection to substrate. For certain applications, such as architecture coatings, the appearance after a long term service is essential. Therefore, the ability for a coating to resist dirt pickup becomes part of performance consideration. In the communication results that show the excellent dirt retention resistance of PVDF coatings will be presented.

Reference

[1] S-C. Lin and K. Argasinski, Chapter 7, Fluoropolymers 2: Properties, 1999, edited by Hougham et al. Plenum Press, New York.

[2] ASTM D3719-00 Standard Test Method for Quantifying Dirt Collection on Coated Exterior Panels

Dr. Byung-Koog Jang

Fine Particle Processing Group, Nano Ceramics Center National Institute for Materials Science (NIMS), Tsukuba, Ibaraki, Japan

Title lecture

Microstructure of Nanoporous Zirconia Coatings Fabricated by EB-PVD

Authors

B.K. Jang, Y. Sakka, K. Matsumoto, H. Matsubara and H.T.Kim

Abstract

Electron beam-physical vapor deposition (EB-PVD) is a widely used technique for depositing thermal barrier coatings (TBCs) on metal substrates for high temperature applications, such as gas turbines, in order to improve the thermal efficiency. Low thermal conductivity is one of the most important properties for obtaining superior TBCs. To optimize TBCs for integration into gas turbines, characterization of the relationship between microstructure and thermal properties of the coatings is necessary. This work describes the microstructure of ZrO2-4mol% Y2O3 (YSZ) coatings as a function of the substrate rotation speed.

YSZ coatings were deposited by EB-PVD onto zirconia substrates. Coated specimens formed at different rotation speeds namely stationary, 1, 5 and 20 rpm. The average coating thickness was about 300 μm. X-ray diffraction (XRD) and Raman spectroscopy were used to determine the crystal structures of the phases present and to determine if any preferred orientation developed in the coatings. The YSZ coatings consist of porous-columnar grains containing nano pores. Nano sized pores could be observed around feather-like grains as well as inside of columnar grains. The total porosity and numbers of nano pores of YSZ coatings increased with increasing substrate rotation speed during deposition.

Prof.Dr. Yeon-Gil Jung

School of Nano & Advanced Materials Engineering, Changwon National University, Changwon, Republic of Korea

Title lecture

Dual Coating Process of High Functional Reinforcement Phase in Metal Matrix Composite

Authors

Eun-Hee Kim, Je-Hyun Lee, Yeon-Gil Jung

Abstract

Metal matrix composites (MMCs) have been researched to improve the poor wear resistance of pure metals and to reduce the high friction coefficient of alloys, for possible applications in engineering materials with high performance in energy technology and automobile industry. Therefore, the reinforcement phase, especially ceramic phase, has been incorporated into the metal matrix, which should be well dispersed in the matrix to maximize effects of reinforcement phase. In this work, inoculant, that is ferrosilicon, was used as a core particle for fabrication of reinforcement phase, which has been generally used in foundry industry to improve crystal growth and to restrict formation of cementite. The reinforcement phase has been formed by a dual coating process; (1) first process is the coating of TiC particles on the surface of inoculant to increase mechanical properties of the matrix, and (2) second process is the coating of Ni particles on the TiC-coated inoculant to enhance dispersibility of the TiC-coated one in the matrix. TiC particles were coated onto the surface of inoculant using an inorganic binder converted into glassification phase by the heat treatment following hydrolysis reaction, inducing the enhancement of coating efficiency. The TiC-coated inoculant was coated again by Ni particles. Nickel nitrate (Ni(NO3)2), existing as Ni cation (Ni2+) in aqueous solution under optimum pH value, was used as a precursor of Ni particle. The coating efficiency and morphology have been investigated with contents of inorganic binder and Ni precursor. As the content of inorganic binder is decreased, TiC particles are well coated on the surface of inoculant without any aggregation and localization of TiC particles. The content of Ni2+ on the TiC-coated inoculant is increased with increasing the content of Ni precursor. The reinforcement phase by the dual coating process has been successfully fabricated, expecting the increase in mechanical properties of the matrix owing to the improvement of dispersibility.

Dr. Eun-Hee Kim

School of Nano & Advanced Materials Engineering, Changwon National University, Changwon, Republic of Korea

Title lecture

Preparation of Ni-Coated TiC Particles using Potential Hydrogen (pH) for Dispersion into a Molten Metal

Authors

Eun-Hee Kim, Je-Hyun Lee, Yeon-Gil Jung, Sang-Hoon Lee, Jin-Ju Park, Chang-Kyu Rhee

Abstract

Metal matrix needs to improve mechanical properties such as wear resistance, elastic modulus, and strength, for possible applications in extreme environments and rapid technological advances. One of possible ways is to reinforce ceramic particle into the matrix. In order to achieve these properties, the reinforcement phase must be well dispersed in the matrix. In this work, titanium carbide (TiC) particles coated with nickel (Ni) particles have been prepared using potential hydrogen (pH) for enhancing the dispersion of TiC particles into a molten metal. The coating behavior and morphology have been investigated as functions of the pH in TiC suspension and the heat treatment condition. TiC particles were dispersed in an aqueous solutions of various pH levels, and then nickel nitrate (Ni(NO3)2) as a Ni precursor was added. The concentration of Ni ion (Ni2+) on the surface of TiC particle is affected by the pH of TiC suspension; as the pH increases the concentration of Ni2+ increases, owing to an increase in the attractive force between TiC particle and Ni2+, arising from the negative charge density of TiC particle. Heat treatment was conducted at 500 °C and 1000 °C under both inert (Ar) and reducing (H2) atmospheres. The Ni-coated TiC particles heat-treated at 500 °C under H2 atmosphere indicate the TiC and Ni phases only, whereas those heat-treated at 1000 °C under Ar atmosphere show a titanium oxide (TiO2) with the TiC and Ni phases, which is resulted from the oxidation of TiC particle by oxygen contained in Ar gas. The Ni-coated TiC particles with a face-centered cubic structure show a magnetic property, independent of the heat treatment condition. The dispersibility of TiC particle into a molten metal would be improved through the coating of Ni particle (or phase), due to the enhanced compatibility of TiC particle with a molten metal, resulting in the improvement and reliability of mechanical properties. For the better adhesion and homogeneous coating of Ni particles onto TiC particles without oxidation reaction, it is essential to control the pH of TiC suspension and to determine the most favorable heat treatment condition.

Jae-Hyun Kim

School of Nano & Advanced Materials Engineering, Changwon National University, Changwon, Republic of Korea

Title lecture

Microstructural evolution and thermal stability of layered thermal barrier coatings in cyclic thermal exposure

Authors

Sang-Won Myoung, Jae-Hyun Kim, Sang-Yup Lee, Tae-Woong Kang, Yeon-Gil Jung, Kee-Sung Lee, Ungyu Paik

Abstract

Thermal barrier coatings (TBCs) have been modified with a layered structure in both bond and top coats using different feedstock powders for the top coat (204 C-NS and 204 NS) and the bond coat (METCO 461 NS and AMDRY 9625) in the specialized coating system of TriplexPro-200. The microstructural evolution of the top coat has been investigated under cyclic thermal exposure, including the thermally grown oxide (TGO) layer and the thermal stability at the interface of the bond and top coats, in order to understand the effects of the microstructural design on the thermal durability and damage tolerance of TBCs. Cyclic thermal exposure tests were performed at a surface temperature of 1100 °C with a temperature difference of 150 °C between the surface and bottom of sample, with a dwell time of 1 h for 800 cycles. Three layers in both coats were prepared with different microstructures in the top coat and compositional change in the bond coat. Each layer thickness deposited in both bond and top coats is about 100 and 200 μm, respectively. After 800 cycles, the TBCs with the layered structure show a sound condition without an evidence for delamination at the interface. The mechanical properties of the TBCs with the layered structure are not much degraded with the thermal exposure, compared with the TBCs with the single structure. The TBC with a relatively porous microstructure (204 C-NS) at the base layer indicate better thermal stability at the interface than that with a relatively dense microstructure (204 NS), showing higher damage tolerance in the case of TBC with the relatively dense microstructure at the surface layer. Both layered TBCs become soft and hard with the thermal exposure, and show thin and thick TGO thicknesses, compared with the TBCs of the single structure with 204 NS and 204 C-NS, respectively. AMDRY 9625 and METCO 461 NS as the bond coat indicate better thermal stability with the top coat and the substrate, respectively, in the thermal exposure. The results indicate that the layered TBC with the relatively dense and porous microstructures at the surface and the interface, respectively, is more efficient in protecting the substrate from the thermal exposure and contact environments, with less degradation of mechanical properties.

Dr. Hans Kranenburg

Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands

Title lecture

Self-healing adhesion of coating networks

Authors

J.M. Kranenburg, R. M. Kops, R. P. Sijbesma, R.A.T.M. van Benthem, G. de With

Abstract