Speakers COSI 2010

- Dr. Ingo Alig, Deutsches Kunststoff-Institut, Darmstadt, Germany Deformation mechanisms during latex film formation: Combination of unilateral NMR and NIR

- Dr. Zbigniew Boncza-Tomaszweski, Industrial Chemistry Research Institute, Warzawa, Poland, Novel nanocomposite binders for powder coatings

- Prof.Dr.Stuart Croll, North Dakota State University, Department of Coatings adn Polymeric Materials, USA, Multiphysics Models for the Deterioration of Corrosion Protection provided by Barrier Coatings

- Marcella Gagliardo, AkzoNobel Car Refinishes, Sassenheim, The Netherlands, Embossing Textures into Coatings by Selective UV-radiation

- Prof.Dr. Aharon Gedanken, BAr-Ilan University, Department of Chemistry, Ramat-Gan, Israel, Coating a large variety of surfaces by sonochemical methods: Anti Bacterial, Anti Viral, Anti biofilms and Antifungai Coatings on Textiles and Glasses

- Jorge González, Instituto de Technología Cerámica, Asociacion de Investigación de las Industrias Cerámicas, Universitat Jaume I. Castellón, Spain Correlation between the wear resistance, and the scratch resistance, for nanocomposite coatings

- Gustavo Guerriero, Delft Univeristy of Technology, Department of Aerospace Materials & Manufacturing, Faculty of Aerospace Engineering, Delft, The Netherlands, Development and Characterization of Thermotropic Liquid Crystalline Polymer Coatings on Metallic Surfaces for Aerospace

- Dr. Horst Hintze-Bruening, BASF Coatings GmbH, Muenster, Germany, Layered Particle Based Polymer Composites for Coatings Part III – Textured Coatings Obtained via Lyotropic Liquid Crystals

- Masahiro Ito*, DIC corporation, 12 Yawatakaigandori, Ichihara, Chiba, 290-8585, Japan TEL +43(0)436-41-4941, Performance of Innovative Hybrid Waterborne Resins for Special Coating Applications

- Prof.Dr. Christine Jérôme*, Center for Education and Research on Macromolecules (CERM), University of Liège, B6 Sart-Tilman, Liège, Belgium, Biomimetic coatings with robust antibacterial properties

- Prof.Dr. Andreas Kandelbauer, School of Applied Chemistry, Reutlingen University, Reutlingen, Germany Optimization of powder coating formulations using isoconversional kinetic analysis of thermochemical data

- Prof.Dr. Joseph Keddie, University of Surrey, Department of Physics, Faculty of Engineering & Physical Sciences, Guildford, UK, Patterned Polymer Coatings via Evaporative Lithography

- Dr. Søren Kiil, Technical Univeristy of Denmark, Department of Chemical and Biochemical Engineering, Lyngby, Denmark, Mathematical modelling of simultaneous solvent evaporation and chemical curing in thermoset coatings: A parameter study

- Xinyi Liu, Loughborough University, School of Mechanical and Manufacturing Engineering, Loughborough, Leicestershire, UK, Modelling the mechanical response of Urushi lacquer under changing environmental conditions

- Dr. Jochen Manara, Bavarian Center for Applied Engery Research, Würzburg, Germany, Polymer-Based Pigment Coatings on Flexible Substrates with Spectrally Selective Characteristics to Improve the Thermal Properties

- Prof.Dr. Stéphane Marais, Université de Rouen, Laboratoire « Polymères, Biopolymères, Surfaces », Mont-Saint-Aignan Cedex, France, Diffusion in polyamide 12/montmorillonite nanocomposite films

- Dr. Dirk Mestach*, Nuplex Resins BV, The Netherlands, Synthesis and coating applications of alkyd-acrylic hybrid polymer dispersions

- Dr. Arjan Mol, Delft University of Technology, Department of Materials Science and Engineering, Delft, The Netherlands, The Characterisation and Performance of Ce(dbp)3-Inhibited Epoxy Coatings

- Prof.Dr. Helmut Möwald*, Max Planck Institute of Colloids and Interfaces, Potsdam-Golm, Germany, Nonplanar interfaces in coatings

- Dr. Martin Murray*, Akzo Nobel, UK, Cracking of colloidal coatings upon drying

- Dr. Tinh Nguyen, National Institute of Standards and Technology, Gaithersburg, USA, Degradation and Nanoparticle Release of Nanocomposite Coatings Exposed to UV Radiation

- Tanzeela Nazir Raja, Universiteit van Amsterdam, Van´t Hoff Institute for Molecular Sciences, Amsterdam, the Netherlands Real Time Imaging of film formation of acrylic latex emulsions

- Sudeshna Saha, Université du Québec a Chicoutimi, Canada, Microscopic Assessment of Penetration Characteristics and Coating Thickness Change with Weathering

- Prof.Dr. Nagahiro Saito, EcoTopia Science Institute, Nagoya University, Furo-cho, Chikusa, Nagoya, Japan, Surface Characteristics of Super hydrophilic Polyelectrolyte Bush

- Dr. Guangling Song, Chemical Sciences and Materials Systems Laboratory, GM Global R&D Center, Warren, USA, A dipping E-coating for Mg alloys

- Paul Steeman, DSM Research, Geleen, The Netherlands, A mechanistic study of the effect of pigment loading on the optical properties of powder coatings

- Dr. Volkmar Stenzel, Fraunhofer Institute for Manufacturing Technology and Applied Materials Research (IFAM) in Bremen, Germany, Drag-reducing paints for the reduction of fuel consumption in aviation and shipping

- Prof.Dr. Funda Tihminlioglu, Izmir Institute of Technology, Chemical Engineering Department, Urla Izmir, Turkey, Mechanical and Barrier Properties of Bilayer Corn-Zein Nanocomposite Coated Polypropylene Films

- Sergei Toews, Universität Paderborn, Coating and Surface Technology, Paderborn, Germany, Smart Functionalized Polymer Dispersions for effective mapping of heterogeneous metal surfaces: New Concepts for Corrosion Protection

- Jesus Manuel Vega, Department of Materials Engineering, Degradation and Durability National Centre for Metallurgical Research (CENIM/CSIC), Madrid, Spain, Corrosion inhibition of aluminum by alkyd paints formulated with anion-exchange hydrotalcite

- Dr. Mariëlle Wouters, TNO Science and Industry, Eindhoven, The Netherlands, Surface modification and coatings for medical devices

- Prof.Dr. Limin Wu, Fudan University, Department of Materials Science and Advanced Coating Research Center of China Educational Ministry, Shanghai, P. R. China, Self-Assembly of Nanocomposite Polymer Latex and Structural Color Coatings

- Hossain Yari , Amirkabir University of Technology, Department of Polymer and Color Engineering, Tehran, Iran, A study of biological resistance of an automotive acrylic-melamine clearcoat exposed to bird droppings and tree gums

- Prof.Dr. Shuxue Zhou, Fudan University, Department of Materials Science, Fudan University, Shanghai, P.R. China, Preparation of Transparent UV-curable Nanocomposite Coatings Containing Zirconia Nanocrystals

- * At the COSI conference are two kinds of speakers: invited speakers and regular speakers. Invited speakers have been put forward by one or more of the committee members and are exempted from the paper selection procedure. Invited speakers are still obliged like the committee members to pay the full fee. Regular speakers have submitted a paper to be considered for presentation by the committee members. Regular speakers will be informed of their selection in January 2010. They also are obliged to pay the full fee. COSI only supports reduced fees for students if they either present a poster or give a lecture. Note: There is only a total of 32 lecture spaces of wich ~10 are reseverd for invited speakers.

Dr. Ingo Alig

Deutsches Kunststoff-Institut, Darmstadt, Germany

Title lecture

Deformation mechanisms during latex film formation: Combination of unilateral NMR and NIR

Authors

I. Alig, F. Simon, S. Kunkel, H. Oehler and D. Lellinger

Abstract

Latex film formation has been considered in the literature for many decades (see e.g. [1-3] and references therein). The generally accepted mechanism consists of three stages: (i) evaporation of water which brings the particles into some form of close packing, (ii) deformation of the particles which leads to a structure without voids but still distinguishable particles, and (iii) diffusion of polymer chains across the particle boundaries which yields to a continuous film with indistinguishable particles [2].

In this paper we combined unilateral solid state NMR and near infrared (NIR) spectroscopy for investigation of latex film formation on model dispersions with narrow particle size distribution. NMR data analysis by double exponential decay function, allows time-resolved determination of water and polymer fraction at different (vertical) position in the film. The bulk water fraction was determined simultaneously by NIR. Temperature and humidity were varied systematically to cover a broad parameter-space of film formation conditions.

The paper concentrates in particular on experimental differentiation between deformation regimes, which have been proposed by Routh and Russel [2], as there are wet sintering, capillary deformation, receding water front and dry sintering. Although the theoretical model by Routh and Russel includes some simplifications and the experimental estimation of all input parameters is difficult, our experimental findings could be described qualitatively in the frame of this theory. However, the quantitative estimation of the boundaries between different regimes by the theory deviates significantly from our experimental findings. Here further research including other experimental methods is needed.

References

[1] Keddie JL, Mater. Sci. Eng. Reports, 21 (1997) 101.

[2] Routh AF, Russel WB, Langmuir, 15 (1999) 7762-7773

[3] Routh AF, Zimmerman WB, Chemical Engineering Science 59 (2004) 2961 – 2968

Dr. Zbigniew Boncza-Tomaszweski

Industrial Chemistry Research Institute, Warzawa, Poland

Title lecture

Novel nanocomposite binders for powder coatings

Authors

Zbigniew Boncza-Tomaszewski, Michal Kedzierski, Katarzyna Rucinska

Abstract

Due to continued customer demand for better quality and more durable powder coatings, interest in improving surface flexibility, applications properties (flowing), UV durability, physical damage resistance, storage stability and lower cure temperature has intensified. The achievement of such objectives is, however, the result of a compromise between required characteristics of the polyesters which are physically contradictory: high glass-transition temperature (Tg), low-melt viscosity, slow network build up and high reactivity. To obtain a satisfactory level of mechanical properties the level of molecular weight must be high enough what has a direct impact on the melt viscosity of the polyester. High reactivity will consequently give a fast increase in melt viscosity and will shorten the time available for the coating to flow during film formation. The result will be a rough surface with a strong orange peel. The glass-transition temperature (Tg) of thermosetting powder coatings must be high enough to prevent the individual particles from agglomerating or fusing during transportation and storage. On the other hand, the melt viscosity of the polyester and hardener combination must be low enough to allow good flow and to give a smooth surface.

In order to meet all or most of these requirements binders for thermosetting powder coatings carboxylic polyester and hardener (solid epoxy resins) were prepared containing organically modified natural halloysite aluminosilicate clay mineral with the empirical formula Al2Si2O5(OH)4. Untreated and modified samples of halloysite were characterized by elemental analysis, thermogravimetry, transmission electron microscopy, atomic force microscopy, nuclear magnetic resonance and Fourier transform infrared spectroscopy. Serials of carboxylic polyesters nanocomposites with different of organo-modified halloysite nanotubes were prepared by the in situ polycondesation of dicarboxylic acids and glycols or by addition directly after synthesis.

Coatings containg modified binders were characterized for thermal, mechanical, and morphological properties. Results showed that an increase in the percentage of clay in binders caused an increase of the glass-transition temperature. It was also seen that the thermosetting powder coatings based on modified carboxylic polyester exhibited significantly lower curing time, better flowing, better mechanical properties and were more resistant from agglomerating during storage when compared with the powders based on unmodified binders.

Keywords: nanofiller, halloysite, binder, powder coatings, thermoset curing

Prof.Dr. Stuart Croll

North Dakota State University, Department of Coatings and Polymeric Materials, USA

Title lecture

Multiphysics Models for the Deterioration of Corrosion Protection provided by Barrier Coatings

Authors

B. R. Hinderliter, S. G. Croll

Abstract

Corrosion protective coatings may function in one or more ways, as a barrier to the environment, as a source of corrosion inhibitor if moisture penetrates to the substrate, or as a cathodic protection, e.g. zinc or magnesium rich primers.In any case, the barrier properties are an important component and depend on degradation of the coating film.Often, the protective properties of coatings are evaluated by electrochemical impedance spectroscopy which follows the reduction of the coating impedance due, amongst others, to moisture entering as the coating degrades.Multiphysics and multiscale model calculations show how differences in impedance behaviour with exposure are sensitive to the kinetics and patterns of the water ingress, including the case when the penetration of water is governed by polymer degradation assuming a simple inverse relationship between degradation accumulation and exposure intensity.

Marcella Gagliardo

AkzoNobel Car Refinishes, Sassenheim, The Netherlands

Title lecture

Embossing Textures into Coatings by Selective UV-radiation

Authors

Marcella Gagliardo, Keimpe J. van den Berg

Abstract

Inspired by and making use of the latest UV-technology developed in AkzoNobel, we recently made use of the photo-embossing process[1] to replicate well defined relief structures onto thiol / isocyanate based and radical UV-curable coatings.

In our process, a photo-mask containing pattern of regions transparent to UV-A light is placed at a certain distance from the polymeric wet coating. Upon UV-A irradiation through the mask, a latent image is embossed onto the film surface.[2] The latter, caused by diffusion of monomers from the unexposed to the exposed areas, will transform into a relief structure upon curing of the coating at room temperature.

Simple overhead sheets, with positive or negative prints reproduced by laser-jet printers (< 200 μm) or a laser photo-plotter (5 - 10 μm), were used as photo-masks. Features with a periodicity 40 -640 μm could be replicated. The relief structures had a height of approximately 10 - 20 μm and an excellent mechanical and chemical resistance. The aspect ratio AR was in the range 0.0004 - 0.2. The effect of various processing parameters (e.g. photo-initiator concentration, intensity of the light source, developing temperature and period of the structures) on height and shape of the final relief structure was investigated.

This method is very attractive from an industrial standpoint as there is no contact between the overhead sheet and the coating applied onto the substrate. Furthermore, both high- and semi-gloss textures are easily achieved as any pattern can be reproduced by standard overhead sheets.

Based on the obtained results, scope and limitations of the process will be presented and discussed.

References

[1] C. Witz, C. Sànchez, C. Bastiaansen, D. J. Broer, in Handbook of Polymer Reaction Engineering, Vol. 2 (Eds. T. Meyer, J. Kenrentjes), Wiley-VCH, Weinheim, Germany 2005, Ch. 19.

[2] European Patent Application filed by AkzoNobel, No. 08170061.9, 2008.

Prof.Dr. Aharon Gedanken

BAr-Ilan University, Department of Chemistry, Ramat-Gan, Israel

Title lecture

Coating a large variety of surfaces by sonochemical methods: Anti-Bacterial, Anti-Viral, Anti-biofilms and Antifungai Coatings on Textiles and Glasses

Authors

Aharon Gedanken

Abstract

When Ultrasonic waves collapse near a solid surface microjets are being formed directed towards the solid surface. These microjets are moving at very high speeds >200 m/sec. We are using this phenomenon for coatings nanoparticles on metals, polymers, glasses, ceramics, textiles, and paper. We are using either a one-step or a two-step procedure for the coating process. In the one-step process, we are fabricating the nanoparticles sonochemically, and subsequent to its creation it is pushed towards the substrate. It is embedded strongly in the substrate, and in glass the nanoparticles could penetrate as deep as 60 nm into the glass. In the two-step process the particles are purchased from a commercial company, and the ultrasonic waves are used for "throwing stones" at surfaces. Namely, we use the collapsing g bubbles for throwing the commercial nanoparticles at the substrate.

In my presentation I will present a few applications of the method. The first application will be the coating antibacterial nanoparticles on textiles and glass. Although in our early studies we have used nanosilver for this purpose, lately, we concentrate on nano metal oxides, such as ZnO, CuO, MgO, TiO2, and alumina.

The second application will be the deposition of MgF2 nanoparticles on a glass surface. We will demonstrate the possibility of this fluorides nanomaterials family to restrict bacterial colonization of common biofilm pathogens. This surface inhibits the formation of biofilms of two common nosocomialbiofilm-forming pathogens, i.e. Escherichia coli and Staphylococcus aureus.

The third example will be related to coating a textile fabric with antiviral nanoparticles. Silver (or gold) nanoparticles that are capped with mercaptoethane sulfonate (Ag-MES) were used for this purpose. Effective inhibition of HSV-1 infection in cell culture by the capped nanoparticles was demonstrated, whereas application of the soluble surfactant MES was found ineffective. No toxic effects of these nanoparticles on host cells were observed. Lately,we have demonstrated that it can inhibit also the Influenza virus including the Swine Influenza.

Finally, we will present a machine that can coat 50 meters of fabric roll to rollusing the sonochemical technique

Jorge González

Instituto de Technología Cerámica, Asociacion de Investigación de las Industrias Cerámicas, Universitat Jaume I. Castellón, Spain

Title lecture

Correlation between the wear resistance, and the scratch resistance, for nanocomposite coatings

Authors

Yolanda Bautista, Jessica Gilabert, Jorge González, María Jesús Ibáñez, Vicente Sanz

Abstract

The improvement of the tribological properties by nanocomposite coatings design has been extensive illustrated in the literature. Different wear methods could be used to characterise the behaviour of the coatings but none of them provides information on the property to be modified to optimize their behaviour. The optimization of the material behaviour, using only one wear test should be done by an empirical method.

The nanoscratch test, used in this study, quantitatively characterizes the scratch behaviour of coatings. Between the parameters obtained are the plastic and the elastic deformation, the critical charge to start the scratch, the chipped or other change in the scratch mechanism of the coating. The knowledge of the scratch mechanism allows the optimisation of the material behaviour by a reasoned way.

In the present study has been correlated, the scratch resistance with the wear resistance for nanocomposite coatings. Knowledge of the mechanical properties extracted from the scratch test, support the optimization of the coating against wear.

The study was applied to nanocomposites coatings with different polymer matrix, different percentages of nanoparticles and different nanoparticles sizes.

Gustavo Guerriero

Delft Univeristy of Technology, Department of Aerospace Materials & Manufacturing, Faculty of Aerospace Engineering, Delft, The Netherlands

Title lecture

Development and Characterization of Thermotropic Liquid Crystalline Polymer Coatings on Metallic Surfaces for Aerospace

Authors

G. L. Guerriero, R. C. Alderliesten, T. J. Dingemans, R. Benedictus

Abstract

Liquid-Crystalline Polymers (LCPs) are characterized by a highly ordered mesomorphic phase between the crystalline solid and the isotropic liquid. LCPs are known for their high tensile strength, fracture toughness, dimensional stability, outstanding chemical resistance and barrier properties over a wide temperature range [1]. These properties make them attractive coating materials for applications with very specific requirements, such as for the aerospace industry. Due to poor adhesion properties [2], thermotropic LCPs have not been used as coating materials. On the other hand, since they only can be dissolved using hazardous acids, they can not be applied from solution. Thus, melt processing or powder coating techniques need to be considered.

Recent developments on liquid crystalline thermosets (LCTs) have improved the adhesion property of this material to carbon-, aluminum-, and titanium-based substrates [3]. This new class of LCTs consists of rigid, all-aromatic monomers, with a molecular structure similar to that of Vectra A950TM (a well-known thermoplastic LCP), and terminated with reactive end-groups. These LCTs have the advantage that they can be melt processed over a wide temperature window, i.e. the reactive end-groups remain latent during processing. When the LCT is further heated to temperatures above the cure onset, the end-groups undergo chain extension and crosslinking chemistries compatible with the liquid crystalline mesophase, and a nematic thermoset or network polymer is obtained.

It is our aim to develop a coating process suitable for these new high performance LCTs, and to study their behavior in aerospace applications. Layers of 25μm and 80μm of LCT coating were applied on pre-cleaned and grid-blasted Aluminum by melt pressing the polymers inside the mold. Several characterization methods were used to asses the effects of curing and heat treatments on the thermal, topographical and tribological properties of the coating. In addition, we have also studied the effects of moisture and corrosive environments on the adhesion properties of the coating, and the resistance to different fluids present in the aerospace industry.

Our findings show that fully cured LCT coatings exhibit adhesion properties comparable to that of commercial structural adhesives and show no signs of peeling, swelling or gloss change after exposure to aggressive fluids such as jet fuels, hydraulic oils or anti-icing additives.

Keywords: Liquid crystalline polymers, thermoset, aerospace coatings, adhesion, chemical resistance.

References

[1] C. Noel et. al., Prog. Polym. Sci., 16, 55-110 (1991)

[2] Y. Kurihara et. al. , J. App. Polym. Sci., 108, 85-92 (2008)

[3] A. Knijnenberg et. al., Macromolecules, 39, 6936-6943 (2006)

Biography Gustavo Guerriero

Gustavo Guerriero is a PhD researcher in the Faculty of Aerospace Engineering at the Delft University of Technology, The Netherlands. He obtained his Master in Materials Science with honors, at the National University of San Martin, Argentina. He has investigated thin polymer film waveguides for photonic nanostructures at the Max Plank Institute for Polymer Research (MPIP-Mainz), Germany. His current research focuses on novel Thermotropic Liquid Crystalline Polymers for coatings in aerospace applications. He is a member of the Society for the Advancement of Material and Process Engineering (SAMPE).

Dr. Horst Hintze-Bruening

BASF Coatings GmbH, Muenster, Germany

Title lecture

Layered Particle Based Polymer Composites for Coatings Part III – Textured Coatings Obtained via Lyotropic Liquid Crystals

Authors

Horst Hintze-Bruening, Anne-Lise Troutier-Thuilliez, Fabrice Leroux

Abstract

Limiting the extend of coatings delamination upon stone chipping is becoming crucial within modern automotive coatings bearing reduced numbers of layers or layer thicknesses. Energy dissipation has to be translated into reinforcement and toughening of the material, limitation of crack growth and direction of failure mode to sacrificing loci.

Within the preceding parts I and II we have shown how energy dissipating structures like dispersed intercalated and exfoliated platelets in a heterogeneous polymer matrix as well as self stratifying coatings obtained from a particle controlled spinodal polymer demixing process can be obtained making use of layered double hydroxides as inorganic particles.

This follow-up presentation introduces a bio-inspired approach for highly impact resistant coating materials. Thus layered particle based composites showing a high degree of particle orientation parallel to the substrate surface can be realized via lyotropic liquid crystal phases which form in aqueous dispersions through specific interactions between charged layered nanoparticles and dispersed polymers.

We anticipate our findings will trigger further developments of composites using layered nanoparticles and application affected coating resins.

Biography Dr. Horst Hintze-Bruening

- 1987; Ph.D. in organic chemistry reaction mechanisms of H transfer reactions

- 1987 - today; BASF Coatings GmbH, research department; research interests

- polymer design

- polymer colloids

- adhesion on PP

- precoated films

- hybrid materials

Masahiro Ito*

DIC corporation, 12 Yawatakaigandori, Ichihara, Chiba, 290-8585, Japan

Title lecture

Performance of Innovative Hybrid Waterborne Resins for Special Coating Applications

Authors

Masahiro Ito, Ichiro Azuma, Teruki Kiyohara*, Ichiro Muramatsu

*DIC corporation, 3, Takasago 1-chome, Takaishi, Osaka 592-0001, Japan

Abstract

Hybrid waterborne resins are prepared by taking advantage of acrylic polymer technology. Polysiloxane/acrylic self-emulsification dispersion, chlorinated polypropylene modified acrylic emulsion and emulsifier free UV-curable acrylic dispersion are featured in this presentation. Correlations between structures of the hybrid resins and performances in coating applications are described

Prof.Dr. Christine Jérôme*

Center for Education and Research on Macromolecules (CERM), University of Liège, Liège, Belgium

Title lecture

Biomimetic coatings with robust antibacterial properties

Authors

Emilie Faure, Aurélia Charlot, Valérie Sciannaméa, Sandrine Lenoir, Robert Jérôme, Christine Jérôme, Cécile Van De Weerdt, Joseph Martial, Catherine Archambeau, Nicolas Willet, Anne-Sophie Duwez, Charles-André Fustin and Christophe Detrembleur

Abstract

Because of corrosion and chemical resistance, relevant mechanical and esthetical properties, stainless steel is widely used in the daily life, not only in the building industry but also in the food industry, the appliances or in the medical field, including implants in orthopedic surgery. However, stainless steel is unable to prevent bacteria from adhering, proliferating and forming a resistant biofilm. Therefore, surface modification is needed for providing the metal surface with antibacterial properties. The scientific literature is very rich in describing various methods for imparting antibacterial properties to different inorganic supports. However, the activity of the coating is generally time limited by the diffusion of the biocide in the environment. Novel robust and stable antibacterial coatings on stainless steel are thus highly desirable for the durability of the functionality.

In this communication, we report on an all-in-one approach to prepare robust antimicrobial films on stainless steel[1] using the layer-by-layer deposition of polyelectrolytes. Novel biocidal multilayered polyelectrolyte films in which the polycationic layer is silver loaded and bears 3,4-dihydroxyphenylalanine (DOPA), known as a promoter of adhesion to inorganic surfaces, were deposited onto stainless steel. DOPA was incorporated in the polycationic chains by radical copolymerisation of N-methacrylated DOPA with the commercially available quaternary ammonium salt of 2-(dimethylamino)ethyl methacrylate (DMAEMA+). Polystyrene sulfonate (PSS) was the polyanionic constituent of the films. In order to boost the antibacterial activity of the polycationic layer, AgNO3 was added to the aqueous solution of P(DOPA)-co-P(DMAEMA+), which resulted in the in-situ formation of silver based nanoparticles (Ag0 and AgCl) that are sources of biocial Ag+. The layer-by-layer deposition of aqueous P(DOPA)-co-P(DMAEMA+)/AgCl/Ag0 suspension and aqueous solution of PSS provides stainless steel with high antibacterial activity against Gram-negative E. Coli bacteria. Moreover, after silver depletion, films retain some antimicrobial activity, thanks to the ammonium groups of the copolymer. We will also show how the antibacterial activity of the films can then be easily re-boosted.[1] The multi-functionality of the P(DOPA)-co-P(DMAEMA+) is a key issue in this process (i) the DOPA co-units are anchored to stainless steel, (ii) these co-units reduce partly AgNO3 into Ag0 nanoparticles and stabilize them by chelation, (iii) the chloride counter-anions react with AgNO3 by ionic exchange, leading to the in situ formation of AgCl particles, and (iv) the ammonium groups are responsible for permanent antibacterial activity. Besides the advantage of the all-in-one process, another major advantage of the approach proposed here is the implementation of the whole process of film formation, including the synthesis of P(DOPA)-co-P(DMAEMA+), in aqueous media under very mild conditions. It makes the strategy very attractive for industrial scaling-up and sustainability applications.

Acknowlegments

The authors are grateful to the "Région Wallonne", Arcelor-Mittal and the University of Liège for funding through the research program BIOCOAT. The authors of CERM are also much indebted to the « Politique Scientifique Fédérale » for financial support in the frame of the « Interuniversity Attraction Pôles Programme (PAI VI/27) : Supramolecular Chemistry and Supramolecular Catalysis » C.A.F. and C.D. are "Chercheur Qualifié" and "Maître de Recherche" by the F.N.R.S. (Belgium), respectively, and thank the National Funds for Scientific Research (F.R.S.-F.N.R.S.) for financial support.

References

[1] A. Charlot, V. Sciannamea, S. Lenoir, E. Faure, R. Jerome, C. Jerome, C. Van De Weerdt, J. Martial, C. Archambeau, N. Willet, A.-S. Duwez, C.-A. Fustin, C. Detrembleur, Journal of Materials Chemistry 19, 4117-4125 (2009)

Prof.Dr. Andreas Kandelbauer

School of Applied Chemistry, Reutlingen University, Reutlingen, Germany

Title lecture

Optimization of powder coating formulations using isoconversional kinetic analysis of thermochemical data

Authors

Günter Wuzella1, Arunjunaj Raj Mahendran1, Andreas Kandelbauer

1Kompetenzzentrum Holz GmbH, WOOD Carinthian Competence Center, ST. Veit an der Glan, Austria

Abstract

The principal stages of forming a protective and visually attractive surface with powder coatings are melting, flowing and curing of the solid resin particles. Formation of a homogenous film is critical and the thermal properties of powder coatings need carefully be adjusted. While DSC can be used to measure both the melting and the curing processes and to determine, for example the glass transition temperature of the cured coating directly from the thermograms, still more information can be extracted from the enthalpy signals when more sophisticated methods of data analysis are employed. Isoconversional kinetic analysis techniques such as the Kissinger-Akahira-Sunose (KAS) or the advanced Vyazovkin (VA) approaches allow to calculate time dependencies of physical and chemical processes at various temperatures based on estimates of activation energies which are obtained from dynamic DSC measurements at different heating rates. These methods allow for example, to calculate the time required for a certain degree of curing of the coating at a given temperature or to estimate the degree of cross-linking in the coating after processing the coating under specified processing conditions. When combined with appropriate data sets, it is even possible to draw conclusions on technological properties of actual products. The potential of parameters derived from such isoconversional kinetic analysis methods for the modeling of surface properties of subsequently manufactured laminate composites has recently been demonstrated for liquid resins. With powder coatings, such an analytical approach would greatly deepen the understanding and enhance the possibilities to develop and optimize coating formulations. In the present contribution, the application of isoconversional kinetic analysis of thermo-chemical signals obtained from differential scanning calorimetry for the analysis and optimization of the flowing and curing behavior of powder coating formulations is illustrated and the potential to correlate the thermal properties of the powder coating with surface properties of the coated substrate is discussed.

Biography professor Andreas Kandelbauer

- 2009 - now: Professor at School of Applied Chemistry, Reutlingen University (Surface and Interface Chemistry, Composites)

- 2006 - 2009: University of Natural Resources and Applied Life Sciences, Key Researcher "Surfaces" for WOOD Carinthian Competence Centre

- 2005 - 2006: Deputy Area Manager Kompetenzzentrum Holz GmbH (Area: Natural fibre composites)

- 2002 - 2005: Researcher at FunderMax GmbH, Austria (Surface Technology)

- 2000 - 2003: Doctoral Thesis in the field of biotechnology in textile industry

Prof.Dr. Joseph Keddie

University of Surrey, Department of Physics, Faculty of Engineering & Physical Sciences, Guildford, UK

Title lecture

Patterned Polymer Coatings via Evaporative Lithography

Authors

J.L. Keddie, A.Georgiadis, M. Murray, J. Jennings, S. Emmett, P. Beharrell

Abstract

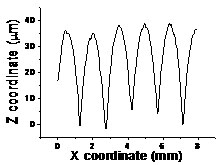

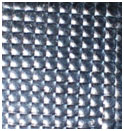

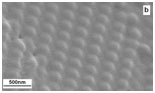

It is well known that the topography of a coating – at both the micrometer and nanometer length scales - has a profound influence on its properties.For instance, surface texture has a pronounced effect on a coating´s wettability, tack, blocking, and gloss.This current research has developed ways to create nearly any-desired pattern of surface topography on a waterborne coating.The method was inspired by a recently proposed approach to creating patterns from colloidal particles in water, called evaporative lithography.[1]This method uses a holey mask to modulate the evaporation rate across the surface of a wet film.In regions where the evaporation rate is higher, the particle concentration becomes higher than in the surrounding region.Water then flows to the concentrated regions to replenish the water that has been lost.This lateral flow carries colloidal particles in the lateral direction.The result is the collection of particles into patterns defined by the mask.

The original reports of evaporative lithography used mono-sized hard particles1 or blends of μm–size and nm-size particles.[2] We have extended the approach by using film-forming latex particles to create coatings with controlled and regular surface undulations.An example of the topography on an acrylic latex film is presented in the figures below. Furthermore, whereas previous work has produced isolated regions of particles, we have created coatings that have an average thickness of tens of micrometers yet still have a patterned surface.The peak-to-valley heights of the features range from a few micrometers up to several millimetres.We have also used latex with a low glass transition temperature to create textured adhesives.

We will present the results of systematic studies of the effects of various process parameters on the geometric features of the resulting surface patterns. A Peclet number is used to describe the relative contributions of lateral flow driven by the differential in evaporation rates in comparison to the Brownian diffusion of particles, which opposes particle concentration in the fast-evaporating areas.We will report the effects of the mask geometry (hole size and spacing between the holes), latex particle size, and solids content on the resulting film topography.Our results are explained through consideration of the Peclet numbers for the experiments.Our method offers the ability to create a bespoke pattern with features having a range of sizes, using an environmentally-friendly waterborne process.

|

|

| Lateral surface profile | Photograph of a 1 cm x 1 cm latex coating |

References

[1] D.J. Harris, H. Hu, J.C. Conrad, and J.A. Lewis (2007) Patterning colloidal films via evaporative lithography. Phys. Rev. Lett. 98, 148301.

[2] D. J. Harris, J. C. Conrad and J. A. Lewis (2009) Evaporative lithographic patterning of binary colloidal films. Phil. Trans. R. Soc. A367, 5157-5165

Associate Dr. Søren Kiil

Technical Univeristy of Denmark, Department of Chemical and Biochemical Engineering, Lyngby, Denmark

Title lecture

Mathematical modelling of simultaneous solvent evaporation and chemical curing in thermoset coatings: A parameter study

Authors

Søren Kiil

Abstract

A fundamental mathematical model, describing the curing behaviour of a two-component, solvent-based, thermoset coating, is used to conduct a parameter study. The model includes curing reactions, solvent intra-film diffusion and evaporation, and film gelation, vitrification, and crosslinking. A case study with a polyisocyanate and a polyol in an organic solvent, catalysed by an organotin compound, is selected for analysis. The transient effects on reactant conversion values and solids content of the film of the following parameters are studied: initial solvent content, film thickness, wind velocity, and bulk air concentration of solvent. Simulations of solvent evaporation are compared to experimental data from a previous investigation. As part of the parameter study, mechanisms of this complex coating system are discussed.

Biography Dr. Søren Kiil

Søren Kiil is an Associate Professor at The Department of Chemical and Biochemical Engineering, Technical University of Denmark. His main research activities are on anticorrosive and antifouling coating systems.

Xinyi Liu

Loughborough University, School of Mechanical and Manufacturing Engineering, Loughborough, Leicestershire, UK

Title lecture

Modelling the mechanical response of Urushi lacquer under changing environmental conditions

Authors

X. Liu, A.Ebrahim, R. D. Wildman and I. A. Ashcroft

Abstract

An analysis of the behaviour of Urushi lacquer has recently been performed. Urushi is a complex natural polymer that has been used to protect and decorate objects for many hundreds of years. Such artefacts are often exposed to environments detrimental to both their aesthetic and mechanical properties and require extensive and continued conservation. However, the precise behaviour of Urushi lacquers is not sufficiently known for us to predict the material response, nor the effectiveness of any proposed conservation route. The work to be presented here aims to resolve this through understanding the constitutive behaviour of thin lacquer layers. We have used mechanical testing procedures to characterise material response to changes in humidity, including mechanical and hygroscopic properties. In addition, we have artificially aged the lacquer to address the effect of ageing on material properties. The identification of these constitutive properties has allowed us to construct a model of Urushi thin layer behaviour under a range of conditions. This model includes hygro-ultraviolet effects to simulate environmental changes, is time dependent and allows us to predict the stresses and strains that develop as the lacquer is subjected to conditions similar to those experienced when exposed to a standard display environment. We will show the results of validation tests performed on a biomaterial strip exposed to fluctuations in humidity and then demonstrate how the model can be used to look at the in situ behaviour of lacquer on an artefact.

Dr. Jochen Manara

Bavarian Center for Applied Engery Research, Würzburg, Germany

Title lecture

Polymer-Based Pigment Coatings on Flexible Substrates with Spectrally Selective Characteristics to Improve the Thermal Properties

Authors

Jochen Manara, Matthias Reidinger, Matthias Rydzek, Mariacarla Arduini-Schuster

Abstract

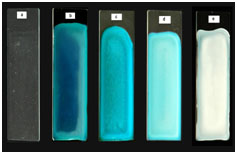

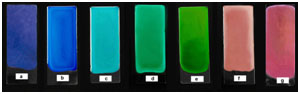

Functional textiles and membranes can create impressive optical effects and are being used increasingly in the field of textile architecture. One example of textile architecture is the New Bangkok International Airport, which is the only building to date in which fabrics with so-called low-e coatings have been used to save cooling energy. At ambient temperature, heat transition onto a surface due to thermal radiation lies in the same order of magnitude as the heat transition caused by convection. A reduction in the thermal emittance leads to improved thermal properties and, in turn, a decrease in heating and/or cooling energy. The low-e coating in Bangkok was applied by use of physical vapor deposition techniques and therefore has the disadvantage that no variation in the silver-colored appearance is possible.

The focus of this work has therefore been to develop spectrally selective coatings on flexible substrates and to characterize and discuss their infrared-optical properties. The main aim was to increase the reflectance in the infrared spectral region to realize low-e coatings which emit only a small amount of thermal radiation. This is combined with a customized color or appearance in the visible spectral region which is important for user acceptance in many applications. The result is a multifunctional alternative to conventional low-e coatings based on continuous metal or metal oxide layers.

The coating consists of colored as well as electrically conduction pigments embedded in a polymeric matrix, such as polyurethane. By adding aluminum particles, for example, to the matrix, it is possible to generate low thermal emittance, but up to now the coatings are inevitably silver-colored or metallic in appearance. Investigations were therefore carried out on the matrix material, the particle sizes and the dispersion of the color and the metal pigments concerning the infrared-optical properties and their optimization. As a result, the spectral emittance of the improved coating is presented from the ultraviolet over the visible up to the far infrared wavelength region. The thermal emittance of a polyester fabric was reduced from above 0.9 to below 0.3 by applying a colored low-e coating. Besides polyester fabrics, glass fiber fabrics, PVC- and EFTE-membranes can also be coated.

For electrically conducting pigments, not only the particle size is of relevance for the radiative properties but also the shape (e.g. spherical or flaky). Therefore, additional theoretical estimations of the influence of the material and the particle consistence on the infrared-optical characteristics are presented.

Biography Dr. Jochen Manara

Dr. Jochen Manara studied physics at the Julius-Maximilians-University Würzburg and received his PhD in 2001. In 2002 he became manager of the Applied IR Metrology group at the Bavarian Center for Applied Energy Research. His current research focuses on the optical and infrared-optical characterization of solids and thin films. This includes the analytical and numerical modelling of radiative transfer through materials and between surfaces. One area of activity is the development of functional polymeric coatings with spectral-selective properties.

Prof.Dr. Stéphane Marais

Université de Rouen, Laboratoire « Polymères, Biopolymères, Surfaces », Mont-Saint-Aignan Cedex, France

Title lecture

Diffusion in polyamide 12/montmorillonite nanocomposite films

Authors

S. Maraisa, B. Alexandre, L. Colasse, P. Médéric, T. Aubry, C. Chappey, D. Langevin

Abstract

Organic-inorganic hybrid systems have received much attention in both scientific and industrial areas due to their enhanced mechanical, optical and barrier properties as well as their flame resistance.

The aim of this work is to study the transport of small molecules through polyamide 12 (PA12)/montmorillonite nanocomposite films prepared by melt blending, using two blending conditions. The addition of Cloisite® Na+ (native montmorillonite) into PA12 leads to microcomposites, whereas the addition of Cloisite® 30B (organo-modified montmorillonite) leads to nanocomposites. The transport mechanisms were investigated by using three probe molecules : nitrogen, water and toluene. While a barrier effect appears clearly with nitrogen, this effect changes with the amount of fillers for water, and disappears for toluene. The reduction of permeability for nitrogen is mainly due to the increase of tortuosity. For water and toluene, the permeation kinetics reveals many concomitant phenomena responsible for the permeation behaviour. Despite the tortuosity effect, the toluene permeability of nanocomposites increases with C30B fraction. The water and toluene molecules interact differently with fillers according to their hydrophilic/hydrophobic character. Moreover, the plasticization phenomena of matrix by water and toluene molecules, involving a concentration dependent diffusion coefficient, are correctly described by the law D=D0eγC. On the basis of the Nielsen´s tortuosity concept, we suggested a new approach of the relative permeability simulation, based not only on the geometrical parameters (aspect ratio, orientation, recovery), but also including phenomenological parameters deduced from structural characterization and permeation kinetics.

Our experimental results reveal that the permeability to gas and vapours of nanocomposite films can be controlled by varying the amount and the nature of nanoclays, and by changing the blend conditions. Thus, the PA12/montmorrillonite films used in this work could be used as thin films to modulate the transport properties of polymeric materials such as stimuli-response coatings.

Keywords: organic-inorganic hybrid systems, nanocomposites; barrier properties, permeability

Dr. Dirk Mestach*

Nuplex Resins BV, The Netherlands

Title lecture

Synthesis and coating applications of alkyd-acrylic hybrid polymer dispersions

Authors

Dirk Mestach, Rob Adolphs, Adam Berry

Abstract

Waterborne resins offer an attractive alternative for the traditional alkyd resins used in interior and exterior trim paints. Unfortunately some of the application properties of waterborne binders are not yet up to standards. Especially properties such as the open time and wet edge time of the applied paint need to be improved in order to obtain the same high quality finishing that was possible with conventional solvent-borne trim paint. Currently, both alkyd emulsions and acrylic polymer dispersions are two frequently used technologies used in the formulation of waterborne VOC-compliant coatings. Coatings based on alkyd emulsions exhibit advantages over those based on acrylic dispersions in terms of gloss, brush-ability, open time, flow and leveling, hiding per coat and adhesion. Advantages of acrylic dispersions over alkyd emulsions include quick drying, durability, non-yellowing, non-embrittling, and non-chalking. Coating formulators therefore often combine acrylic dispersions with alkyd emulsions. The main advantage formulators are looking for are improved film forming properties due to the presence of alkyd moieties, which typically have a low glass transition temperature. However, the presence of the alkyd and especially the presence of substantial quantities of surfactant used in the production of the alkyd emulsion, results in some critical problems, such as soft films (causing dirt pick-up and poor block resistance). Another problem that may be encountered is the occurrence of phase separation between the binders due to incompatibility. Therefore the use of alkyd-acrylic composite binders, prepared by means of mini-emulsion polymerization offers interesting perspectives. In this paper the development and optimization of such hybrid polymer dispersions is discussed.

Dr. Arjan Mol

Delft University of Technology, Department of Materials Science and Engineering, Delft, The Netherlands

Title lecture

The Characterisation and Performance of Ce(dbp)3-Inhibited Epoxy Coatings

Authors

J. Mardel, S.J. Garcia, P.A. Corrigan, T. Markley, A.E. Hughes, T.H. Muster, D. Lau, T.G. Harvey, A.M. Glenn, P.A. White, S.G. Hardin, C. Luo, X. Zhou, G.E. Thompson, J.M.C. Mol

Abstract

Since the beginning of the 20th century hexavalent chromium-based anti-corrosion pigments have been incorporated into organic coatings providing excellent corrosion protection to underlying metal substrates. Nevertheless, the high toxicity and recent very strict and international legislative restrictions have led to an increasing need for the development of new pigments with reduced ecological footprints and at least similar anticorrosion properties to those shown by chromates. The emergence of rare earth organophosphates as corrosion inhibitors has been an expanding area of research in recent years. Interest in this area is based on the development of bi-functional inhibitors that incorporate the good cathodic inhibition qualities of the rare earths as well as the potential for anodic inhibition from the organophosphate functionality which is an anion in solution, making this compound a prime candidate for incorporation into an epoxy coating as a candidate for a chromate-free primer.

The objective of this study is to gain detailed understanding of the effect of the incorporation of Ce(dbp)3 into an epoxy paint film from (i) the characterisation perspective, (ii) the release kinetics of the inhibitor from the paint and (iii) the degree of inhibition provided to metals coated with the inhibited paint. With respect to the first aim, the Ce(dbp)3/epoxy film was examined using scanning electron microscopy (SEM), transmission electron microscopy (TEM), Fourier transform infrared spectroscopy (FTIR) and dynamic mechanical thermal analysis (DMTA). For the release kinetics, water uptake into an epoxy film and the release of cerium were monitored as a function of immersion time in 0.1M NaCl solution. Specifically, weight loss/gain was used in combination with FTIR to examine the water uptake and ICP was used to determine the amount of Ce3+ released from the primer as a function of time. The corrosion performance under immersion conditions was studied using electrochemical impedance spectroscopy (EIS) and the filiform corrosion susceptibility was assessed by accelerated testing. Sections of the Ce(dbp)3/epoxy film were made after the performance testing and electron microscopy was used to examine the interface between the inhibited epoxy and the AA2024-T3 aerospace aluminium alloy substrate. It was found that the epoxy with the highest loading of Ce(dbp)3 showed the best corrosion performance. The primer also showed improved adhesion after immersion testing. It was found using SEM and TEM that the corrosion protection offered by the Ce(dbp)3-inhibited epoxy primer and the improved adhesion were due to the development of an interfacial oxide at the metal/primer interface.

Prof.Dr. Helmut Möwald*

Max Planck Institute of Colloids and Interfaces, Potsdam-Golm, Germany

Title lecture

Nonplanar interfaces in coatings

Authors

Helmut Möwald, D.G. Shchukin

Abstract

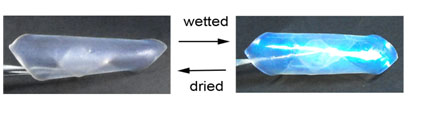

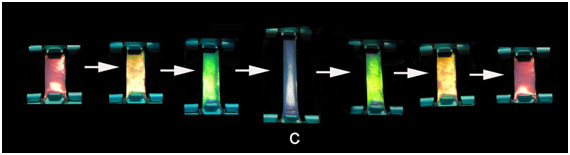

Organic coatings on inorganic surfaces are expected to serve many purposes from col-our and glance to protection, but they may also take up active functions of the material. The latter is more demanding and appears at this stage more the domain of scientists than of application engineers and manufactures. But it may be rewarding looking into the future and for this I will give some examples in this lecture from my own environment. Nearly 20 year ago the so-called layer-by-layer technique has been developed in my department where a film is built by consecutive adsorption of alternatingly charged polyelectrolytes. /1/ It turns out that this yields films with nm precision and can be applied with any type of multiply charged materials. Because the film stability relies on many bonds these films are very stable, but because the interactions can be manipulated via salt, pH or temperature they can also be weakened. The films can be prepared on any charged support, and if the latter is inert it can by activated e.g. by plasma /2/ or ultrasonic treatment. /3/ The use of these functions for anticorrosion coatings will be discussed in a separate contribution, and this presentation will be concentrating on the more "futuristic" applications, and these predominantly result from preparing multicomponent films.

- Preparing films with polymeric and plate-like inorganic sheets one may arrive at mechanically reinforced films providing also a permeation barrier, e.g. for water. /4/

- Films can serve as a drug depot and in response to external conditions (or demand) a drug can by released. /5/

- By doping a film with metallic nanoparticles it may be made IR sensitive. One thus can create locally high temperature with a time dependence given by the laser source.

- This on one hand may by made use of creating nanosized melted spots for information storage. /6/ On the other hand embedding lipid vesicles with well-defined melting transition one may trigger the release of their content. /7/

- Light triggered release can by also applied to release anticorrosion agents on preselected spots. /8/

- Since the coating is effected by adsorption it is not confined to planar surfaces. Thus also particles can be coated, and by this humidity sensitive particles can be protected. This has been found successful for hydrogen storage materials. /9/

- For coating of nanoparticles a more suitable technique is to synthesise polymers on them or to graft smaller polymers. The particles are interfacially active, and they therefore may function as large tensides. Since the coating may be made stimuli responsive the interfacial activity may be drastically varied. This enables use of these particles in processes, e.g. as switchable emulsion stabilizer, and they may later function as efficient compatibilizer due to more than 100 bonds extending from 1 particle. /10/

- As a most sophisticated system one may consider superhydrophobic surfaces due to a coating by a snow-flake hierarchical system with base unit a fullerene derivative self-organizing into a lamellar structure. /11/

Literature

- G. Decher and J.D. Hong: Macromol.Chem.Macromol.Symp., 46 (1991) 321

- Y. Lvov, H. Haas, G. Decher, H. Möhwald, A. Kalachev: J.Phys.Chem. 97 (1993) 12835

- D.V. Andreeva, D. Fix, H. Möhwald, D.G. Shchukin: Adv. Mater. 20 (2008) 2789

- E. Geraud et al. : Chem. Mater. 20 (2008) 5139

- D. Volodkin et al. : Langmuir 25 (2009) 14037

- A. Skirtach et al. :Appl. Phys. Lett. 94 (2009)

- D. Volodkin et al. : Angew. Chem. 48 (2009) 1807

- K. Skorb et al : Chem. Comm. (2009) 6041

- T. Borodina et al : Appl. Mat. Interf. 1 (2009) 996

- E. Edwards et al. : Angew. Chem. 47 (2008) 320

- T. Nakanishi et al.: Adv. Mater 20 (2008) 443

Dr. Martin W. Murray*

AkzoNobel Colloids and Complex Fluids ECG, Wilton Centre, Wilton, Redcar, Cleveland, UK

Title lecture

Cracking of colloidal coatings upon drying

Authors

Martin W. Murray

Abstract

The cracking of colloidal coatings upon drying is of significant interest to industry.Cracking can compromise the protective properties of barrier coatings, the transport properties of e.g. electrical coatings and can detract from the aesthetic nature of decorative coatings.Thus understanding the driving forces that control cracking and how such forces can be ameliorated is commercially important to coatings companies such as AkzoNobel. Further, the legislative drive to remove coalescing solvents from coating formulations has put greater pressure on understanding and controlling the cracking of industrially relevant formulations.

All colloidal formulations can be made to crack upon drying if prepared at sufficient thickness.Above this critical cracking thickness (CCT) the stress developed during drying is greater than the yield stress of the networked particles and hence leads to cracking.The focus of our work has been to understand where the CCT lies for a given formulation, what controls the CCT and what can be done to change it.

Our work, and that of others, has shown the importance of the capillary pressure generated during drying on controlling the cracking behaviour of any given formulation.The capillary pressure is determined by the nature of the particles present within the formulation – in particular their specific surface area (SSA).During drying as the liquid menisci recede into the packed particle structure of the coating a capillary pressure is generated which puts the particle network under compression and the coating under tension.It is the tension within the coating that causes the cracking.

The talk will review the drivers for the coatings industry in this area, detail how drying and cracking develop within colloidal formulations and review the current understanding and the challenges that remain.

Dr. Tinh Nguyen

National Institute of Standards and Technology, Gaithersburg, USA

Title lecture

Degradation and Nanoparticle Release of Nanocomposite Coatings Exposed to UV Radiation

Authors

Tinh Nguyen, Bastien Pellegrin, Xiaohong Gu, Paul Stutzman, Alexander Shapiro, Eric Byrd, and Joannie Chin

Abstract

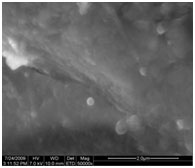

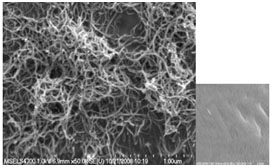

Nanoparticles are increasingly used to enhance multiple properties of polymeric materials. However, recent research suggests that nanoparticles might have negative effects on the environments and health safety. Since polymers are susceptible to photodegradation by solar UV radiation, nanoparticles imbedded in a polymer coating will eventually be released into the environments during their life cycles. Such a release of nanoparticles might have a great effect to the environments and present a roadblock onpotential uses of nanocomposite coatings. This study investigates the degradation and nanoparticle release of an amine-cured diglycidyl ether of bisphenol A epoxy coating containing multi-walled carbon nanotubes (MWCNTs) and silica nanoparticles. Nanocomposite films of approximately 150 μm were prepared by drawdown technique. Specially-designed cells containing nanocomposite coating specimens were exposed to 75 %RH, 50 °C, and UV radiation between 295 nm and 400 nm in the well-controlled NIST-developed SPHERE UV chamber. Exposed specimens were removed at specified time intervals for measurements of chemical degradation, mass loss, and nanoparticle release using a variety of analytical techniques. The amounts and rates of nanoparticle release were determined by thermogravimetry and inductively coupled plasma atomic emission spectroscopy (ICP-AES). The results show that amine-cured epoxy coatings containing MWCNTs exposed to UV radiation chemically degrade at a much slower rate than the unfilled or nanosilica-filled epoxy coatings do. Microscopic and elemental analyses of the nanoparticle collector surface as a function of exposure time present direct evidence of the silica nanoparticles released (Figure 1), and the rate and amount of released silica nanoparticles follow closely with the rates of mass loss of the exposed nanocomposite samples. On the other hand, photodegradation of the matrix in the epoxy/MWCNT film results in a large concentration increase and network aggregation of MWCNTs on the nanocomposite film surface (Figure 2). Postulations on polymer photo-stabilization of CNTs and model for CNT network aggregation at the nanocomposite surface will be presented.

|

|

| Figure 1: SEM image of the nanoparticle collector surface after 60 d exposure to UV, clearly showing silica nanoparticles released from the epoxy/5% (mass) nanosilica composite coating. | Figure 2. SEM image of the epoxy/0.72%(mass) MWCNT composite coating surface after 60d exposure to UV, showing clearly the network aggregation of CNTs at composite surface; (the unexposed surface was smooth and absent of CNTs as shown in the low right image). |

Tanzeela Nazir Raja

Universiteit van Amsterdam, Van´t Hoff Institute for Molecular Sciences, Amsterdam, the Netherlands

Title lecture

Real Time Imaging of film formation of acrylic latex emulsions

Authors

Tanzeela N. Raja, Albert M. Brouwer, Koen Biemans, Tijs Nabuurs and Ronald Tennebroek

Abstract

Waterborne organic coatings have gained much attention due to the use of water as solvent instead of toxic volatile organic compounds (VOC). They can be formed by emulsion polymerization method in which particle size ranges from few to several hundred nanometers. Film formation of water-based emulsion polymers is a complicated and multistage process.Physical and mechanical properties of final film depend upon the nature of the polymer as well as the method of film formation. Coalescing agents play a crucial role in film formation. A limited amount of organic solvent or coalescing agent is needed to get a crack free, smooth and homogenous film.

Biography Tanzeela Nazir Raja

Currently I am a Ph.D student in Molecular Photonics group at Van ’t Hoff Institute for Molecular Sciences (HIMS) University of Amsterdam. Title of my PhD project is 3D Imaging of Film Formation; it is funded by Dutch Polymer Institute (DPI). In this project I am involved to explore film formation dynamics of waterborne organic coatings by making use of fluorescence techniques.

My previous education is from Pakistan. I did my Masters (1999) and M.Phil (2001) in Organic Chemistry. After that I got a job and in Pakistan Council of Scientific & Industrial Research (2002-2006) Lahore Pakistan and joined there as a Scientific Officer. There I worked in Applied Chemistry Research Centre for three years and then left to Amsterdam for my PhD studies which started in September 2006.

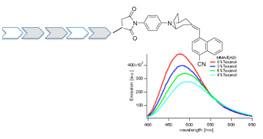

Co-polymerized perylene orange acrylate labeled hydrophobic acrylic latex film on confocal fluorescence microscope

We have been engaged in this research project to investigate various stages of film formation and to get more insight in the dynamics involved during the film formation process by utilizing fluorescence methods. Hydrophobic and hydrophilic acrylic polymer emulsions were selected for this study. Stryene/2-ethylhexyl acrylate and methyl methacrylate/ethyl acrylate present the co-polymers of hydrophobic and hydrophilic polymer emulsions, respectively. These polymer latices were synthesized via seeded emulsion polymerization which produced ~110-120 nm size latex particles. By changing the monomer ratios materials of low (ca. 20 °C) and high (ca. 60 °C) Tg were prepared.

Labeling of emulsion polymers was done by covalently linking an organic fluorescent probe to the polymer the backbone. An environment-sensitive fluorescent probe (maleimidofluorotrope, MFT) was covalently linked to the co-polymer in the latex, which efficiently detects the amount of co-solvent in the bulk latex as well as in latex film. Perylene red and perylene orange acrylate are fluorescent probes used to study film formation on the confocal microscopy. Role of co-solvent in film formation and investigation of film formation dynamics was the main focus of our investigation. Steady-state, time-resolved fluorescence and confocal fluorescence microscopy were employed as characterization techniques in fluorescence method. Five coalescing agents were used in this study; 2,2,4-trimethyl-1,3-pentanediol mono(2-methyl propanoate) (texanol), di(propylene glycol) n-butyl ether (DPnB), ethylene glycol ethyl hexyl ether (EEH), di(propylene glycol) methyl ether (DPM) and ethylene glycol ethyl ether acetate (EEA).

Co-polymerized-MFT in methyl methacrylate/ethylacrylate latex detected various %ages of Texanol on steady-state fluorescence

Steady-state and time-resolved fluorescence techniques provided spectral and lifetime information of co-polymerized MFT. The position of the fluorescence emission maximum of MFT can be used to measure the amount of coalescing agent present in the polymer particles. 2D and 3D confocal images provided information of the particle sizes at different stages of film formation. Coalescence and diffusion of latex particles was observed on the confocal microscopy.

Sudeshna Saha

Université du Québec a Chicoutimi, Canada

Title lecture

Microscopic Assessment of Penetration Characteristics and Coating Thickness Change with Weathering

Authors

Sudeshna Saha, Duygu Kocaefe, Cornelia Krause, Tommy Larouche

Abstract

Changes in the intrinsic properties of heat-treated wood resulting from detrimental effects of extended exposure to outer environment especially to UV portion of solar radiation and water (in the form of moisture or rain) often cause a serious problem in appearance of the surface due to the chain scission reactions. Moreover, the repeated temperature and humidity variations of the ambient environment subject the wood to wet and dry cycles which result in swelling and retraction, consequently, creates cracks and fissures. These in turn lead to the exposure of the wood´s sub superficial layers to atmospheric agents and the progressive degradation of the wood surfaces and sub surfaces. These facts forced wood industries to move towards the exploration of a non toxic transparent coating for UV protection of heat-treated wood. Coating selection for exterior use often requires a balance between aesthetic (clear coatings) and protection (colored coatings) for a particular application. Water based acrylic polyurethane coatings are highly efficient, non toxic and durable coatings with upgraded film properties. The performance characteristic of these coatings are enhanced by incorporating natural antioxidant (bark extract) and inorganic UV absorbers (nano and micro titania and nano zinc oxide). The main objectives of this study are to investigate the wetting and penetration characteristic of these new coatings on the wood surface and changes in coating thickness with weathering time. Adhesion is the main criteria for a good coating performance which eventually improves resistance against outside environment and also the durability of the coatings. The adhesion characteristic of the coatings can easily be measured by wettability of different coatings on the wood surface of interest. In this study the work of adhesion calculated according to Young-Dupré equation based on the interaction at the interface between the coating material (liquid phase) and the wood surface (solid phase). Fluorescence microscope is a very important tool to determine the penetration characteristic of different coatings into wood cells. The penetration behavior is well correlated with the adhesion performance of coatings to the wood surface. In this study, three different water based acrylic polyurethane coatings are analyzed in order to establish the correlation between the thickness of the coatings and the UV exposure time. The tissue deformation characteristics beneath the coating surface are observed after weathering. Coating thickness decrease with increase in weathering time is also reported. A significant difference is observed for early wood and late wood penetration behavior and their implication is discussed.

Prof.Dr. Nagahiro Saito

EcoTopia Science Institute, Nagoya University, Furo-cho, Chikusa, Nagoya, Japan

Title lecture

Surface Characteristics of Super hydrophilic Polyelectrolyte Bush

Authors

J. Hieda, S-J. Kim, N. Saito

Abstract

Polymer brush surface, which the polymer chains grafted at a high density, is expected to be new coating technology for the control of friction, adhesion, biomolecules adsorption. In particular, the polyelectrolyte brush grafted on a spherical surface particle show a strong interaction among proteins at a low ionic strength whereas less protein is adsorbed at a high ionic strength. This property originates from the counterion effect. Moreover the effect results in most stable superhydrophilic surface.

In this study, polyelectrolyte brush with sodium sulfonate was synthesized varying ratios of dissociable-group, and the surface properties were characterized in wettability, zeta-potential and protein adsorption behavior.

Polystyrene (PS) trichlorosilane was grafted to the polystyrene brush (PSB) surface. PSB was converted to polystyrene sulfonate sodium salt brush (PSSB) by sulfonation and neutralization processes. Silicon wafer and glass was used as substrates. The ratio of sulfo-group was varied by different reaction time durations. The PSSB with the maximum ration takes the water contact angle of almost 0 degree. The sample surfaces were characterized by XPS, CARS (coherent anti-stokes Raman spectroscopy), zeta-potential. In protein adsorption experiment, solutions of bovine serum albumin (BSA) in various ionic strength solutions were used. The ionic strength of the solvent was adjusted with NaCl. Protein adsorption behavior on PSSB surface was evaluated by optical evanescent adsorption spectroscopy (OEAS), QCM and AFM. OEAS results show BSA is adsorbed on 80% sulfo-group PSSB more than 50% sulfo-group PSSB surface. Thus the amount of adsorption depends on that of dissociable-groups. Sodium ions can move in a given space. On contrary, sulfo acid was fixed on the polymer chains, that is, the substrate surface. Such a situation result in the specific adsorption of proteins. The specific adsorption was discussed from the viewpoint of water layer on the PSSB bush by CARS results.

Dr. Guangling Song

Chemical Sciences and Materials Systems Laboratory, GM Global R&D Center, Warren, USA

Title lecture

A dipping E-coating for Mg alloys

Authors

Guang-Ling Song

Abstract

Mg alloys are becoming more and more important structural materials in the automotive industry. However, most commercial Mg alloys require coating protection for their poor corrosion performance in applications. In this study, a self-deposited "electroless" E-coating process is proposed and developed for Mg alloys. By utilizing the unique electrochemical performance of Mg, a thin film is rapidly formed on the surface of a Mg alloy through simply dipping the alloy coupon in an E-coating bath solution without applying a current or potential that is essentially required in a normal E-coating process. It is believed that the surface alkalization effect of Mg is responsible for the deposition of the pre-film of the "electroless" E-coating and the diffusion of hydroxyls in the porous film is governing the growth of the film. The rapidly formed film can offer sufficient corrosion protection for the magnesium alloy in a chloride-containing environment or a phosphating bath in a paint line. The stability of the film can be further significantly improved after curing. The simple dipping coating process can be easily applied to various Mg alloys. It is found that the coating performance is influenced by the substrate Mg alloy, which can be ascribed to the composition and stability of the substrate.

Paul Steeman

DSM Research, Geleen, The Netherlands

Title lecture

A mechanistic study of the effect of pigment loading on the optical properties of powder coatings

Authors

Paul Steeman, Konraad Dullaert, Jurjen Bolks, Leendert Molhoek

Abstract

With the drive for more economic coating processes there is a desire in the market for powder coatings with an improved hiding power at reduced layer thickness. In principle this can be achieved by increasing the amount of pigment in the powder coating composition. However, it is well known that increasing the pigment loading of powder coatings negatively affects the appearance of the cured coating. When using titanium dioxide white pigment, the gloss of the coating typically drops upon loading the coating with more than about 45 wt% of pigment. At the same time the haze, the diffuse optical scattering, increases significantly. In this paper we report on a mechanistic study to understand the optical properties of powder coatings. First, the relation between the microscopic details of the surface texture on the one hand and the optical properties like gloss and haze on the other hand is investigated. Next, it is shown how the texture development is related to the powder coating flow during cure. Finally, it is shown how powder coating flow is affected by increasing the loading of the pigment. A detailed study of the interactions between resin binder and pigment revealed the root cause of the loss of optical properties. Via a tailored modification of these interactions we have been able to develop a novel powder coating binder systems that allows TiO2 loading up to 60wt%, offering a much better hiding power in combination with a good appearance. This has been recently commercialized in the HiTone® powder coating series.

Dr. Volkmar Stenzel

Fraunhofer Institute for Manufacturing Technology and Applied Materials Research (IFAM) in Bremen, Germany

Title lecture

Drag-reducing paints for the reduction of fuel consumption in aviation and shipping

Authors

Volkmar Stenzel

Abstract

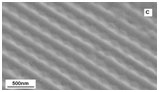

In October 2009 the European Commission has decided that the fuel consumption for aviation and shipping has to be reduced by 10%, respectively 20% until 2020. A significant contribution to this challenging goal could be a coating that reduces drag.

Since approx. 20 years it is well known that special microstructures ("riblets") can lead to a drag-reduction by up to 10%. A new process for a production of such microstructured coatings on large surfaces will be presented. This technique consists of a process that allows paint application, embossing and partly curing in one single step. The coating material consists of VOC-free nanocomposites that give the coating the necessary abrasion resistance and weathering stability.

An overview about the current status of the process and the paint development will be given. Additionally first results of in-service tests on an aircraft and about the results of tests in a ship model basin, indicating a wall friction reduction by more than 5%, will be presented.

Prof.Dr. Funda Tihminlioglu

Izmir Institute of Technology, Chemical Engineering Department, Urla Izmir, Turkey

Title lecture

Mechanical and Barrier Properties of Bilayer Corn-Zein Nanocomposite Coated Polypropylene Films

Authors

Ozcalik Onur, Tihminlioglu Funda

Abstract

Biopolymers offer a noticeable potential of replacing conventional petroleum based polymers in food packaging materials. Protein based biopolymers including corn zein can be processed in to films and have excellent barrier to gases and moderate barrier to water vapor. Characteristic disadvantages of biopolymers such as low mechanical strength and dependency of their characteristics to moisture should be improved by utilization of nanocomposite applications that draw attention in many fields of material science. Although there are some studies concerning the utilization of nanocomposite applications of protein based polymers such as wheat gluten and soy protein, to our knowledge there is no study related to corn zein nanocomposite coating.

Therefore, in this study, a novel corn–zein coating structure on polypropylene (PP) films was developed to examine its feasibility as an alternative water vapor and oxygen-barrier for flexible packaging industry. Bilayer films were produced by casting corn zein nanocomposites (CZNC) on commercial polypropylene (PP) films. CZ-NC were prepared by solution intercalation of organomodified layered silicates (OMLS). The barrier properties of the resulting films were evaluated as a function of OMLS concentration. Mechanical and optical properties of the films were also investigated. The results of the study showed good dispersion of OMLS within zein matrix up to 7.5% OMLS, predicted as exfoliated structures obtained by XRD chromatograms. The mechanical properties such as Young modulus and strength at break values were improved with the addition ofOMLS into polymer matrix, however, the optical clarity of the samples were not affected significantly. The gas permeability values of the films decreased significantly depending on the filler concentration The decrease in gas permeability of the bilayer films is believed to be due to the presence of ordered dispersed clay nanoparticle layers with large aspect ratios in the polymer matrix.This causes an increase in effective path length for diffusion of gas into polymer matrix.Consequently, corn zein nanocomposite coatings could be used as abarrier layer in food packaging applications.

Sergei Toews

Universität Paderborn, Coating and Surface Technology, Paderborn, Germany

Title lecture

Smart Functionalized Polymer Dispersions for effective mapping of heterogeneous metal surfaces: New Concepts for Corrosion Protection

Authors

Sergej Toews, Wolfgang Bremser, Horst Hintze-Bruening, Sebastian Sinnwell, Michael Dornbusch, Rafael Bautista-Mester, Winfried Kreis

Abstract

The development of environmental friendly coatings for corrosion protection of steel continues to attract a great deal of attention. Within this paper we present a new concept for corrosion protection based on functionalised water borne latexes and their application to heterogeneous metal surfaces such as hot dip galvanized (HDG) steel.

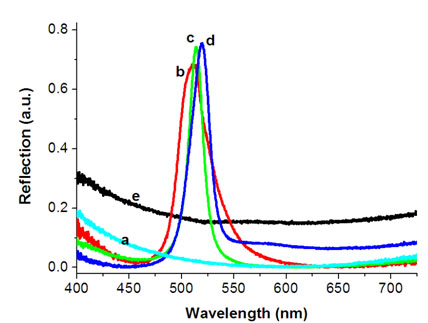

It is well known that industrial HDG steel samples show a heterogeneous surface. In the first part of this paper we characterised the different surface chemistry. The characterisation of the surface was performed with a high lateral resolution on a nanometre scale by Scanning Auger Microscopy (SAM) and Energy Dispersive X-Ray Spectroscopy (EDX) attached to an ultra high resolution Field Emission Scanning Electron Microscopy (FESEM). The electrochemical mapping was obtained by a micro Scanning Capillary Cell (SCC) and Scanning Kelvin Probe – Force Microscopy (SKP-FM).