Posters COSI 2011

Applied Coatings

- Massimiliano Barletta [1], Dipartimento di Ingegneria Meccanica, Università degli Studi di Roma Tor Vergata, Roma, Italy, On the deposition of photocatalytic films on flat substrates.

- Reza Golbedaghi [2], Payame Noor University, Hamedan, Iran, Chitosan membrane modified by RF O2 Plasma and Surface TiO2 nanoparticle coated.

- Isaias Hilerio [3], UAM Distrito Federal, Mexico, Coating characterization in CrN deposited by magnetron sputtering method in AISI 316 steel.

- Alexander Irzh [4], Bar Ilan University, Ramat-Gan, Israel, Novel deposition method of metal and metal-oxide nanoparticles on various surfaces using microwave plasma.

- Sudagar Jothi [5], Jilin University, Changchun, China, Chromium-free conversion pre-treatments for the efficient electroless Ni-P deposition on AZ91D magnesium alloy.

- Sang-Chul Jung [6], Sunchon National University, Sunchon, South-Korea, Effects of microwave, UV, and O3 on the propylene gas degradation by photocatalytic reaction with CVD TiO2 films.

- Sun-Jae Kim [7], Sejong University, Seoul, South-Korea, Preparation of Various Metal Ions Doped Hydrogen Titanate Nano Particle Coated Thin Films by Layer-by-Layer Self-Assembling Method for an Electrochromic Electrode.

- Juan Rodrigo Laguna-Camacho [8], Universidad Veracruzana, Poza Rica de Hidalgo, Mexico, Solid particle erosion on coatings employed to protect die casting molds.

- Heon Lee [9], Sunchon National University, Sunchon, South-Korea, The effect of combined processes for advanced oxidation of organic dye using CVD TiO2 film photocatalysts.

- Dulce Yolotzin Medina [10], Universidad Autonoma Metropolitana, Mexico D.F., Mexico, Characterization of La2O3 films doped with Terbium produced by Ultrasonic Spray Pyrolysis.

- Dulce Yolotzin Medina [11], Universidad Autonoma Metropolitana, Mexico D.F, Mexico, Effect of Al2O3/ZrO2/TiO2 double-layer coating obtained by spray pyrolysis technique on hydrogen permeation of 304 stainless steel.

- Gite Vikas [12], North Maharashtra University , Jalgaon, Maharashtra, India, Synthesis of renewable source (vegetable oils) based polyurethanes resins for industrial coating.

- Gite Vikas [13], North Maharashtra University, Jalgaon, Maharashtra, India, Preparation and Properties of eco-friendly two pack PU coatings based on Renewable source (Sorbitol) and its property improvement by nano ZnO.

- Delong Xie [14], Chemistry and Chemical Engineering, Guangzhou, China, Preparation of acrylate redispersible polymer powders and its application in coatings.

Characterization and Modelling

- Koen Adema [15], Laboratory of Materials and Interface Chemistry, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Eindhoven, the Netherlands, Depletion layers in nanocomposite coatings.

- Manuel García-Rubio [16], Airbus Operations S.L., Getafe, Spain, Effect of the pretreatment on the long-term corrosion resistance of Cr (VI)-loaded and Cr (VI)-free paint systems on AA2024. Electrochemical Impedance Spectroscopy characterisation.

- Yasar Kahraman [17], Sakarya University, Engineering Faculty, Adapazari, Turkey, A Comparision of Residual Stresses Developed in Different Thermal Barrier Coatings for Gas Turbine Blades Characterization and modelling.

- Alexander Kröger [18], University of Paderborn, Coatings and Colloids / CTB, Paderborn, Germany, Stability and characterization of modified graphene dispersions.

- Nora Pollmann [19], University of Paderborn, Paderborn, Germany, Dynamic Mechanical Analysis and Atomic Force Microscopy of Inorganic-Organic-Hybridpolymers.

- Maria Serdechnova [20], L´Ecole nationale supérieure de chimie de Paris, Paris, France, Role of Mg2+ and PO43- for sacrificial protection of steel by aluminum pigment in model high temperature. coatings

- Dr. Roland Emmerich [20-2], Robert Bosch GmbH, Packaging Technology, Bosch Lab Systems, Waiblingen, Germany, High-throughput-analysis of chemical resistance by gloss measurement.

Corrosion

- Ersin Arslan [21], Ataturk University, Erzurum, Turkey, The Investigation of the Tribocorrosion Properties of DLC coatings deposited on Ti6Al4V Alloys by CFUBMS.

- Wolfgang Ensinger [22], Technical University Darmstadt, Darmstadt, Germany, Nanofilms of a Surface-Near Platinum/Tantalum Alloy Formed by Ion Implantation for Reducing Hydrogen Embrittlement of Tantalum.

- Yaiza González-García [23], Delft University of Technology, Delft, The Netherlands, Local electrochemical evaluation of self-healing coatings for corrosion protection of metals.

- Kristina Kohlgrüber [24], University of Paderborn, Colloids & Coatings C&C/CTB, Paderborn, Germany, Surface modification of zinc particles - Application in a corrosion protection primer.

- Bahram Ramezanzadeh [25], Amirkabir University of Technology, Department of Polymer Engineering and Color, Tehran, Iran, A study on the cathodic delamination and anticorrosion performance of an epoxy composite on the steel samples treated by Cr(VI) free conversion coatings.

Functional Coatings

- Guy Applerot [26], Bar-Ilan University, Ramat-Gan, Israel, Ultrasound radiation as a technique for the production of antibacterial nanocomposite textiles.

- Ersin Arslan [27], Ataturk University, Erzurum, Turkey, Comparison of structure and tribological properties of MoS2-Ti films deposited by biased-dc and pulsed-dc.

- Camille Carcouët [28], Laboratory of Materials and Interface Chemistry, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Eindhoven, The Netherlands, Synthetic approaches for raspberry-like particles leading to transparent superhydrophobic coatings.

- I.D. Gunbas [29], Laboratory of Polymer Chemistry, Eindhoven University of Technology, Eindhoven, The Netherlands, Hydrophobic coating using Poly(dimethylsiloxane) (PDMS)-grafted polystyrene maleic anhydride (PSMA) copolymer on cotton fabric and washing durability.

- Tae woong Kang [30], Changwon National University, Changwon, South-Korea, Thickness effect on thermal properties of thermal barrier coatings with thermal exposure.

- Mohsen Mohseni [31], Amirkabir University of Technology, Tehran, Iran, Self-cleaning Automotive Clear Coats; Part 1: Films Behavior against Bilogical Degradation.

- Jörg Ressel [32], University of Paderborn, Coatings and Colloids C&C/CTB, Paderborn, Germany, Ultra Low Friction Coatings via Polyamidimid-Polydimethylsiloxane-Block-Copolymers.

- Jianfang Wang [33], National University of Defense Technology, Changsha, China, Effect of Surface Microstructure on Hydrophobicity of Coating.

Hybrid Materials and Nanocomposites

- Carola Esposito Corcione [34], University of Salento, Lecce, Italy, UV-cured polymer-boehmite nanocomposite as protective coatings for wood-based elements.

- Eun-Hee Kim [35] , School of Nano and Advanced Materials Engineering, Changwon National University, Changwon, South-Korea, South-Korea Fabrication and mechanical properties of Al2O3 based multi-phase composite through surface charge.

- Prof. Dr. Célia Malfatti [36], UFRGS, Porto Alegre, Brazil, Zinc-talc composite coatings post-treated with γ-methacryloxypropyl-trimethoxysilane and tetraethoxysilane with cerium salt addition.

- Prof. Dr. Célia Malfatti [37], UFRGS, Porto Alegre, Brazil, γ-methacryloxypropyl-trimethoxysilane and tetraethoxysilane silane precursors : applied as a post-treatment of ZnNi coatings .

Interfaces and Adhesion

- Mohsen Mohseni [38], Amirkabir University of Technology, Tehran, Iran, Quantifying the Interfacial Interaction of Various Silane Treated Nano Silicas with A Polyurethane Coating Using Tensile Strength and Dynamic Mechanical Thermal Analysis Experiments.

- Xiaolong Zhang [39], TNO Den Helder, The Netherlands, Influence of surface preparation on the corrosion performance of epoxy coatings for ship ballast tank.

Material Properties

- Sudagar Jothi [40], Jilin University, Changchun, China, The Performance of surfactant on the surface characteristics of electroless on magnesium alloy .

- Ying-Chieh Lee [41], Department of Materials Engineering National Pingtung University of Technology, Pingtung, Taiwan, The Effect of Mg Dopant on Microstructure and Phase Transformation of ZnTiO3 Thin Films.

Photochemistry

- Wu Menghua [42] , Dipartimento di Chimica, Materiali e Ingegneria Chimica, Politecnico di Milano, Milano,Italy, UV-resistant amorphous fluorinated coating for anodized titanium surfaces.

Applied Coatings

prof.dr. Massimiliano Barletta

Dipartimento di Ingegneria Meccanica, Università degli Studi di Roma Tor Vergata, Roma (Italy),

Title lecture

On the deposition of photocatalytic films on flat substrates

Authors

M. Barletta, S. Vesco, F. Menenti

Abstract

Synthesis of highly active photocatalytic species is a well established technique. Different viable solutions are available to prepare nano-particles or very small agglomerates of photo-active materials, which, if exposed to UV radiations, moisture and oxygen, can give rise to the formation of powerful radicals. When such radicals come in touch with organic materials, they can exert their strongly oxidative power and activate degradation process. The development of self-cleaning or easy-to-clean self-sanitizing surface is the main application of such a class of material.

Unfortunately, whilst a great deal of knowledge is currently available to synthetize the photo-active species, little information are still available to deposit them on the surfaces of different substrates. In particular, the formation of highly active and durable photocatalytic films is still at the beginning. Basically, two are the techniques which allow the deposition of photocatalytic films: (i) the ‘in-situ’ synthesis of the photocatalytic species, that is, the synthesis of the active species by reaction at high or moderate temperature inside a film already deposited on the substrate; (ii) the synthesis of the active species in lab and the preparation of inorganic-organic formulations which can be deposited and consolidated through regular deposition and curing methods. In the present investigation, we will review all the available solutions and promote some new ones, thus emphasizing the ‘plus and minus’ of each technology.

Reza Golbedaghi

Department of Chemistry, Payame Noor University (PNU), Iran

Title lecture

Chitosan membrane modified by RF O2 Plasma and Surface TiO2 nanoparticle coated

Authors

B. Jaleh , R. Golbedaghi, N. gholami M. Farshchi-Tabrizi P. Wanichapichart

Abstract

Chitosan membrane were prepared and investigated for surface modification using O2 plasma produced at low pressures with Radio Frequency (RF) at power 30 W. The influence of the plasma treatment on the basic properties of the membranes, namely morphology, flow rate, hydrophilicity, and TiO2 adsorption has been studied using AFM, SEM, UV-visible spectroscopy, FTIR and contact angle measurement. The decrease of the mean pore diameter confirmed by decreasing water flux for TiO2-coated chitosan membrane. In determining the flux, the hydrophilicity of the surface played a role as important as that of the micropore size. The contact angle with water decreases and wettabilities increases with plasma treatment. Analyses of AFM images show with increasing treatment time that roughness of surface changes. SEM shows TiO2 particles agglomeration is absorbed on in the surface of membrane. The FTIR-ATR spectra of the O2 plasma-treated chitosan and TiO2-coated chitosan membranes were compared with the spectrum of the untreated chitosan. The absorption of TiO2 nanoparticles on the surface of chitosan membrane reference and plasma treated sample were investigated by UV-Vis spectroscopy.

Isaias Hilerio

U. Autónoma Metropolitana, U. Azcapotzalco, A México, D.F. , MÉXICO.

Title lecture

Coating Characterization in CrN Deposited by Magnetron Sputtering Method on AlSi 316 Steel

Authors

I. Hilerio, M. Vite M. Moreno, M.A.Barron

Abstract

Chromium Nitride (CrN) thin films were deposited on AISI steel 316 substrates by means of the reactive magnetron sputtering method. CrN films were produced under two different conditions. In the first one, the substrate was heated by a DC source. For the second coating a negative substrate bias voltage was applied. X ray diffraction, quantitative energy dispersion and scanning electron microscope were employed to characterize the two different phases, their chemical composition as well as their microstructure. In addition, a microhardness test was carried out. The results show that a better phase formation of CrN thin films was achieved when a heating source was present (first case). Both coatings presented homogeneous surface. Their compositions show differences even when the gases flowing are the same in composition. Regarding to the hardness test results, there can be found a higher value when using a heating source.

Alexander Irzh

Department of Chemistry and Kanbar Laboratory for Nanomaterials at the Bar-Ilan University Center for Advanced Materials and Nanotechnology, Bar-Ilan University, Ramat-Gan, Israel

Title lecture

Novel deposition method of metal and metal-oxide nanoparticles on various surfaces using microwave plasma

Authors

Alexander Irzh, Guy Applerot, Isaschar Genish and Aharon Gedanken

Abstract

This work presents a method to deposit wide assortment of inorganic materials on various surfaces. In most of the studied cases the metal precursor was dissolved in ethanol, and this solution homogeneously spread on the surface. By using microwave (MW) plasma we successfully obtained many inorganic materials, including pure metals (Au, Ag, Pt, Pd, Ni, Co and Zn) and metal oxides (ZnO, MgO, TiO2, ZrOM2, SrO and Eu2O3.). Pure metals were obtained by plasma reduction mechanism and metal oxides produced by thermal decomposition of the precursors inside the plasma. Most of these materials were successfully deposited on dielectric (glass, quartz, polymers) or/and conducting (Si, Al, stainless still) surfaces. This study also shows the proposed mechanism of metal and metal oxide formation in MW plasma. All obtained materials was characterized by physical and chemical techniques like X-Ray Diffraction (XRD), Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM), Atomic Force Microscopy (AFM), Time Of Flight Secondary Ion Mass Spectrometry (TOF-SIMS), Electron Spin Resonance (ESR), contact angle measurements and electrical resistance measurements.

Jothi Sudagar

Department of Materials Science and Engineering, Nanling campus, Jilin University, Changchun, China

Title lecture

Chromium-free conversion pre-treatments for the efficient electroless Ni-P deposition on AZ91D magnesium alloy

Authors

Jothi sudagar, Jianshe Lian, Rasu Elansezhian

Abstract

In this present study, Phosphate-manganese-molybdate, Vanadium and organic based-Tannic conversion coatings were used as an efficient pre-treatment for the electroless metal deposition on AZ91D magnesium alloy by catalytic surface activation. These propound pre-treatment layers on the substrate minimize the corrosion of magnesium during metal depositon process and moreover mitigate the potential difference between the magnesium matrix and the depositing metal phase. The corrosion tests were performed by immersion (1M HCl) and electrochemical test (3.5 wt% NaCl), for the both with and without catalytic activated. All the coated samples exhibited active-passive potentiodynamic polarization behavior. The results suggest that the zero current potential, passive current density and breakdown potential increased after the addition. As a consequence, the corrosion current desity (Icorr) reached least and corrosion potential (Ecorr) approached towords positive direction. The surface flatness (by SEM) and increasing amonophous plus nanocrystalline nickel phase (by X-RD) were the reasons accounting for the significant increase in corrosion resistance. In addition, these three chromium-free pre-treaments had also marginal influence.

Sang-Chul Jung

Department of Environmental Engineering, Sunchon National University, Jeonnam, Korea

Title lecture

Effects of microwave, UV, and O3 on the propylene gas degradation by photocatalytic reaction with CVD TiO2films>

Authors

Y.S. Bae, D.G. Ra, S.J. Kim, B.H. Kim, S.G. Seo, S.C. Jung

Abstract

A microwave/UV/ozone/TiO2 photocatalysts hybrid process system, in which various techniques that have been used for propylene gas treatment are combined, is evaluated to develop an advanced technology to air pollutants efficiently. TiO2 photocatalyst balls used were prepared using a low pressure metal organic chemical vapor deposition. Microwave/UV/TiO2 photocatalyst hybrid process showed higher degradation efficiency than microwave/UV/alumina balls hybrid process. The degradation efficiency increased almost linearly with increasing ozone dose. The lower the propylene inlet concentration was the higher degradation efficiency. The double bond of propylene is broken by ozone and OH, resulting in production of CH4 and C2H6. These two intermediate products are mineralized into CO2, H2O, and CO. C2H4 and C3H8 are suggested to be produced from CH4, C2H6 and C3H6 by microwave.

Sun-Jae Kim

Nanomaterials Laboratory, INAME/Faculty of Nanotechnology and Advanced Materials Engineering, Sejong University, Seoul, Korea

Title lecture

Preparation of Various Metal Ions Doped Hydrogen Titanate Nano Particle Coated Thin Films by Layer-by-Layer Self-Assembling Method for an Electrochromic Electrode

Authors

Hyo-Jin Oh, Kyung-Jong Noh, Hye-Kyung Ku, Ju-Ri Lee, Sang-Chul Jung, Won-Jae Lee and Sun-Jae Kim

Abstract

Three kinds of metal ions (Fe, W, and Li) doped hydrogen titanates were hydrothermally prepared at 130 °C for 48 hrs in a strong basic solution, and then were directly coated on fluorine-doped tin oxide glass substrate using layer-by-layer self assembling method, by means of dispersing them in distilled water, for an electrochromic electrode material. Prepared powders were fully characterized using SEM, XRD, cycle voltammetry and colorimeter. All the prepared titanate nano particles were confirmed consisting of layered structures by XRD analysis. Particle shape of Li-doped titanate powder alone had nano-sheet shape, whereas other metal ion doped titanate powders had nanotubular shape. Electrode coated using Fe-doped hydrogen titanate with nanotubular shape showed the best reversible reaction resulting in faster response time and deeper color than other titanate coated films due to enhanced electrical conductivity by doping and to large interface area between electrode and electrolyte.

Juan Rodrigo Laguna-Camacho

Universidad Veracruzana, Faculty of Electric and Mechanical Engineering, Poza Rica, Veracruz, México

Title lecture

Solid particle erosion on coatings employed to protect die casting molds

Authors

J.R. Laguna--Camacho, L.A. Cruz-Mendoza, J.C. Anzelmetti-Zaragoza, A. Marquina-Chàvez, M. Vite-Torres

Abstract

In this study, the performance of coatings that were subjected to solid particle erosion tests was evaluated. These coatings can be used to protect die casting molds. The main interest of this research project was to find possible alternatives to increase the wear resistance of these mechanical components. Die Casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity, which is machined into two hardened tool steel or coated dies. Most die castings are made from non-ferrous metals, such as aluminium, copper, magnesium, lead, zinc, tin based alloys but also they can be protected by specific coatings that have high wear resistance. The erosive wear damage in die casting molds is caused due to the molten metal is blown into the mold by high pressure dry air. Filling the mold cavities during the blown step, molten metal and sand particles impact the internal surface producing erosive wear damage. Coatings such as Chromium Nitride (CrN) and Titanium Aluminium Nitride (TiAlN) that exhibit low wear damage in these types of applications due to high abrasion and erosion resistance were tested. In addition, uncoated 4140 steel and 6160 aluminium were also tested. An erosion test rig similar to that shown in ASTM G76-95 standard was designed and built to perform the tests. The abrasive particle used was angular silicon carbide (SiC) with a particle size of 420-450 &mu:m. Tests were carried out using different impact angles (30°, 45°, 60° and 90°) with a particle velocity of 24± 2 m/s and an abrasive flow rate of 0.7 ± 0.5 g/min. The particle velocity and the abrasive flow rate were low in all of the tests to reduce the interaction between the incident particles and the rebounding particles in the system. The surfaces were examined with a scanning electron microscope (SEM) to characterize the erosive damage. The wear mechanisms identified were pitting and ploughing action at low impact angles (α = 45°) due to sliding component commonly observed at these incident angles whereas bigger craters, radial cracks and a more roughened surfaces were seen at angles near or at 90°.In addition, it was observed that the damaged area was extended in all of the cases at 30° and 45° reducing considerably at 60° and 90°. The wear scars were characterized by an elliptical shape at 30° and 45°, which is a characteristic feature when the specimens are impacted at low-incident angles (α = 45°) whereas a roghly circular was seen at 60° and 90°.

Heon Lee

Department of Environmental Engineering, Sunchon National University, Jeonnam, Korea

Title lecture

The effect of combined processes for advanced oxidation of organic dye using CVD TiO2 film photocatalysts

Authors

H. Lee, S.H. Park, S.J. Kim, B.H. Kim, H.S. Yoon, S.C. Jung

Abstract

We studied the preparation of TiO2 photocatalyst films on alumina balls by Low Pressure Metal Organic chemical vapor deposition using titanium tetraisopropoxide and also on the photocatalytic activity for decomposition of methylene blue using a microwave/UV/auxiliary oxidants/TiO2 photocatalyst hybrid process system. In particular, the objective of this study is to develop a novel advanced oxidation process that overcomes the limitations of existing single-process water treatment methods by adding microwave irradiation to maximize the formation of active intermediate products, e.g., OH radicals, with the aid of UV irradiation by microwave discharge electrodeless lamp, photo-catalysts, and auxiliary oxidants. The results of photocatalytic degradation of methylene blue showed that the decomposition rate increased with the DO concentration and microwave intensity. When an auxiliary oxidant such as ozone or hydrogen peroxide was added to the microwave-assisted photocatalysis, however, a synergy effect that enhanced the reaction rate considerably was observed.

Dulce Yolotzin Medina

División de Ciencias Básicas e IngenierÍa, Universidad Autónoma Metropolitana-Azcapotzalco, Azcapotzalco, México D. F., México

Title lecture

Characterization of La2O3 films doped with Terbium produced by Ultrasonic Spray Pyrolysis

Authors

D.Y. Medina, S. Orozco, R. T. Hernandez, I. Hilerio I. Hernadez.

Abstract

In this work the characterization of La2O4:Tb3+ films prepared by ultrasonic spray pyrolysis is reported. The films were prepared from lanthanum and europium nitrates over a Corning glass substrate. The films structure was analyzed by X-ray diffraction (XRD), Microscopy Electronic and EDS analysis. Photoluminescence (PL) were performed. The spectrum consists of the charge transfer peak at 340 nm and the emission spectrum, excited at 340 nm, shows The transitions of the Tb3+ ion: 5D4 → 7FJ: J = 3(625 nm), 4(560 nm), 5(545 nm), 6(490 nm). The strongest emission peak at 545 nm corresponds to the 5D4 → 7F5 transition.

Dulce Yolotzin Medina

Materials Department, UAM-Azcapoztalco, Azcapotzalco, México D.F., México

Title lecture

Effect of Al2O3/ZrO2/TiO2 double-layer coating obtained by spray pyrolysis technique on hydrogen permeation of 304 stainless steel

Authors

R. T. Hernández L., V. Cortes S., D. Medina V., I. Hilerio C.., J. Guzmán S. , and S. Orozco S.

Abstract

Coated double-layer every one formed by aluminum/zirconium/titanium oxides coatings films were deposit over 304 stainless steel surface to reduce the hydrogen embrittlement effect. A electrochemical cell was used for hydrogen charged. Tensile test are do in the samples with or without coating. The embrittlement percent factor and the SEM micrographics indicate a reduction of permeation hydrogen for coated samples.

Gite Vikas

Department of Polymer Chemistry, School of Chemical Sciences, North Maharashtra University, Jalgaon, Maharashtra, India

Title lecture

Synthesis of renewable source (vegetable oils) based polyurethanes resins for industrial coating

Authors

V. V. Gite, A.B. Chaudhari, D. G. Hundiwale, R. D. Kulkarni

Abstract

Presently the polymers are prepared from the exhaustible petroleum sources. These sources are limited and one day will finish. Hence renewable source based polymers i.e. derived from non-petrochemical feed stocks are gaining great deal of momentum from both economical and environmental senses. Main renewable feed stocks used for polymers are oils, carbohydrates, cellulose and other natural polymers. In the present work vegetable oils such as linseed, sunflower, almond, coconut, mustered, rice bran and castor oils are utilized for synthesis of low molecular weight polyols as sustainable resources. These polyols were prepared by transesterification of oils with glycerol using catalyst litharge. The prepared polyols were used for preparation of PU coatings, by reacting polyols with MDI as an isocyanate part. The ratio of NCO/OH was maintained for 1.2:1 and the catalyst DBTDL was used. PUs were coated on metallic panels and cured at room temperature. These coating are characterized for their coating properties such as gloss, alkali and acid resistance, scratch resistance, flexibility and adhesion Obtained coating were applied for wire enamels, appliance finishes with incorporation of nanoparticles for improvement of coating properties.

Gite Vikas

Department of Polymer Chemistry, School of Chemical Sciences, North Maharashtra University, Jalgaon, Maharashtra, India

Title lecture

Preparation and Properties of eco-friendly two pack PU coatings based on Renewable source (Sorbitol) and its property improvement by nano ZnO

Authors

V. V. Gite1, A. Anand2, R. D. Kulkarni2,

Abstract

Today most of the coating formulations are based on petroleum sources. These sources are limited. Therefore, it is necessary to use any eco-friendly renewable source for making polymers, as they are renewable and may be non hazardous, easily available and cheaper. In present work we selected sorbitol as a renewable source, which is derived from naturally occurring polymer i.e. cellulose. The technology of converting cellulose to sorbitol is well established. Hence we directly utilized sorbitol in preparation of polyols. These polyols were synthesized with the help of sorbitol, 1, 2, 3, 6-tetrahydro phthalic anhydride, adipic acid, diethylene glycol and zinc acetate (catalyst). The synthesized polyols were characterized for their acid value, hydroxyl value, IR spectroscopy, etc. The above mentioned polyol is further used in PU coatings after reacting with polyisocyanates. For further improvement in properties, these coatings were prepared by adding nano ZnO. This ZnO was prepared in the laboratory and characterized for its size by SEM. The prepared PU coatings were analyzed for their coating properties such as gloss, scratch resistance, flexibility, chemical properties and anticorrosive properties. Moreover, distribution of nano particles in the PU coatings and surface morphology of PU coatings were studied by SEM.

Delong Xie

Research Institute of Chemical Engineering, School of Chemistry and Chemical Engineering, South China University of Technology, Guangzhou, China

Title lecture

Preparation of acrylate redispersible polymer powders and its application in coatings

Authors

Delong Xie, Xinya Zhang, Yanping He, Huanqin Chen

Abstract

Acrylate redispersible polymer powders were prepared by spray drying, where silica-sol and inorganic powders were used as anti-caking agents. The effect of drying condition on the performance of redispersible latex powders was studied, it was found that the optimal conditions was as follow: the inlet temperature was 150 °C, the outlet temperature was 78 °C, the rotation speed of atomizing disc was 21000-24000 r/min and the feed rate was 80g/min. Then putty and finish two in one interior wall coating was prepared with the above re-dispersible polymer powders as film forming materials and cement as hydraulic inorganic binder. The effect of re-dispersible polymer powders was studied in detail. The experimental results showed that the re-dispersible polymer powders has great influence on the putty and finish two in one interior wall coating, and the coating has good properties when content of re-dispersible polymer powders is 4~6%.

Characterization and Modelling

Koen Adema

Laboratory of Materials and Interface Chemistry, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Eindhoven, the Netherlands

Title lecture

Depletion layers in nanocomposite coatings

Authors

K.N.S. Adema, G. de With.

Abstract

The formation of depletion layers near the interfaces of nanocomposite coatings is often detrimental for their performance. In this study, we investigate whether the formation of depletion layers can be understood in terms of Van der Waals (vdW) interactions between filler particles and the substrate or superstrate of a binary composite coating. Next to an experimental investigation, the dispersion interactions expected to regulate this phenomenon are modeled and calculated using Lifshitz theory, Effective Medium Theory and Hamaker-hybrid geometrical models. Calculations indicate that the effective range of the vdW interactions is limited to a natural length scale in the system, such as the size of a filler particle. Depletion layer thicknesses of much larger size might prove explainable in terms of a larger natural length scale, such as the correlation length of a structured network of filler particles. A correct way of implementing a correlation length into a vdW model has not yet been found.

Manuel García-Rubio

Department Surface Technologies, Engineering of Materials and Processes, Airbus Operations S.L., Getafe, Spain

Title lecture

Effect of the pretreatment on the long-term corrosion resistance of Cr (VI)-loaded and Cr (VI)-free paint systems on AA2024. Electrochemical Impedance Spectroscopy characterization

Authors

M. García-Rubio, P. Ocón, A. Lavía, I. García

Abstract

The surface of AA2024 specimens were either pickled, immersed in a chemical conversion coating or anodized in a tartaric acid-sulphuric acid (TSA) bath prior application of a Cr (VI)-loaded or a Cr (VI)-free primer. This six coating systems were immersed in 0.5 M NaCl corrosive solution up to 3000 h, and their changes in the electrochemical response where measured by means of Electrochemical Impedance Spectroscopy. The results showed both water-based primers are prone to absorb water after 24 h immersion and therefore, the aqueous electrolyte can reach rapidly the coating/alloy surface. The best pretreatment was found to be the Cr (VI)-free TSA anodic film. Interestingly, a robust EIS response for long immersion time was found for the TSA+ Cr-free primer system; which was comparable to the TSA+ Cr (VI)-loaded system.

Yasar Kahraman

Sakarya University, Engineering Faculty, Adapazari, Turkey

Title lecture

A Comparision of Residual Stresses Developed in Different Thermal Barrier Coatings for Gas Turbine Blades

Authors

Y. Kahraman, I. Taymaz

Abstract

Ceramic thermal barrier coatings have been developed for advanced gas turbine and diesel engine applications to improve engine reliability and fuel efficiency. Blades and vanes of the high-pressure turbine stages of aero-engines are the most highly stressed parts in engineering components. The blade geometry was objected to airflow at the temperatures about 800 °C. These high gas turbine temperatures can only be maintained through advanced cooling techniques like electro-beam physical vapor deposition (EB-PVD) and thermal barrier coatings (TBCs). Such TBCs consist of thin ceramic layers of low thermal conductivity, yttrium stabilized zirconia (YSZ) which are applied on the blade surface. The coating imparts good adhesion of the ceramic to the substrate. In this study, 3-D finite element structural and thermal analyses were carried out on both uncoated (without coating) and ceramic-coated turbine blade using ANSYS code. A 150 micron super alloy bond coating (NiCrAlY) was first applied to the turbine blade. Then, the blade was covered by thickness of 350 micron top coating for three different materials for comparing as to which one protects from the residual stresses than the others. These materials are Mullit (3Al2O3.2SiO2), YSZ and "60% mullit and 40% YSZ". These analysis were performed for detecting the possible thermally problem spots. Then the blade's thermal stressed problematic areas were determined by the finite element simulations which were important for the improving blade and TBC.

Alexander Kröger

University of Paderborn, Coatings and Colloids / CTB, Paderborn, Germany

Title lecture

Stability and characterization of modified graphene dispersions

Authors

Alexander Kröger, Karl Hiltrop, Wolfgang Bremser

Abstract

Since its discovery in 2004, graphene and graphene composites have attracted steadily increasing interest from a physical and chemical point of view. Graphene's preparation and extraordinary physical properties are two central points of interest. The chemical and electronic nature of the carbon allotrope allows its modification and dispersion-based exfoliation with several substance classes. Hernandez et al. reported successful exfoliation of graphene in N-methyl pyrrolidone resulting in few layer graphene with a moderate amount of single layers [1]. We successfully exfoliated graphite in presence of hexamethoxymethyl melamine (HMMM), polybenzimidazoles (PBI) and Diphenyl ethylene (DPE) dispersion precursors. Exfoliation experiments were conducted using mild ultrasound over several hours. After sedimentation of non-exfoliated graphite, the characteristically grayish to black colored supernatant were collected and analyzed. The dispersions were characterized with microscopic methods (optical microscopy, AFM, and SEM), dynamic light scattering and zeta potential measurements.

References

- Hernandez, Y.; Nicolosi, V.; et al., Nat. Nanotechnol., 2008, 3, 563

Nora Pollmann

University of Paderborn, Paderborn, Germany

Title lecture

Dynamic Mechanical Analysis and Atomic Force Microscopy of Inorganic-Organic-Hybridpolymers

Authors

N. Pollmann, W. Bemser, O. Seewald, K. Kleine

Abstract

Hybrid materials play an important role in materialscience. In the present work, compounds with ethoxysilanes as functional groups have been synthesized; those compounds cure under humid conditions and ambient temperatures according to the sol-gel-process in order to form inorganic domains. With the help of dynamical mechanical thermal analysis (DMA) and microhardness tests, the properties of the cured films were determined. AFM analysis enables the determination of the Young modulus and the force of adhesion between probe (SiN3) and sample. Earlier investigations have shown that nanoscale differences between harder and softer segments can be detected. [1] Through this measurement, the size of highly inorganic domains can be estimated. It was found that not only the inorganic amount, but also the size of the inorganic domain influences the film properties.

References

- Oliver, W.C., Pharr, G.M J. Mater. Res. 1992 7, 1564-1583

Maria Serdechnova

Ecole nationale supérieure de chimie de Paris (ENSCP), Paris, France

Title lecture

Role of Mg2+ and PO43- for sacrificial protection of steel by aluminum pigment in model high temperature coatings

Authors

Presenting M. Serdechnova, Co-authors P. Volovitch, K. Ogle

Abstract

Atomic emission spectroelectrochemistry (AESEC) was used for measuring the reactivity of aluminum in a model high temperature pain system. For this paint the dissolution of the siloxane binder, the dissolution of the metal pigments (particle size >10μm), pigment particle detachment and steel dissolution under the coating can all be monitored simultaneously. To simulate these phenomena under more controlled conditions, the reactivity of bulk aluminum in electrolyte containing dissolved additives was also investigated. It was demonstrated by AESEC that the behavior of the system changes dramatically in the presence of additives: no galvanic protection without additives and very strong protection in presence of them. The paint system without additives is related to the low conductivity between the steel and the sacrificial pigments due to the resistance of aluminum oxide and of the siloxane binder. The presence of Mg2+ and PO43- leads to the modification of aluminum oxide layer and binder structure, reducing of the resistance for both of them. As a result, the electrical contact between steel and pigment allows galvanic protection in the presence of these pigments.

Dr. Roland Emmerich

Robert Bosch GmbH, Packaging Technology, Bosch Lab Systems, Waiblingen, Germany

Title lecture

High-throughput-analysis of chemical resistance by gloss measurement

Authors

G. Meichsner, R. Hiesgen, S. Linder, Esslingen Univ. of Appl. Sci., Esslingen, Germany

R. Emmerich, T. Burk, Bosch Lab Systems, Waiblingen, Germany

Abstract

In our poster we explain how a conventional gloss meter can be used for analysing the chemical resistance of a coating. Chemicals are dosed on the coating surface in identical, small volumes for forming droplets. The sample is afterwards tempered in an oven at a constant temperature or with a temperature gradient. Finally the damaged area is analysed by scanning the gloss meter stepwise over the etched spots and recording gloss values. As an example etching with diluted sulphuric acid at different temperatures is shown. It can be seen that the peak area in the gloss measurement diagram is a measure for the degree of etching. The results of our experiments showed that the chemical resistance of coatings is measureable by gloss changes even. Gloss changes not visible to the naked eye are detectable using a commercial gloss meter. A stepwise linear shift of the gloss meter over the etched area delivers a convoluted signal which can be used for quantifying damages. This analysis method can be automated and is therefore suitable for High Throughput Experimentation. It provides information on the chemical resistance of a coating and gives insight into properties affecting the chemical resistance such as the crosslink density.

Corrosion

Ersin Arslan

Erzurum College of Vocational, Ataturk University, Erzurum, Turkey

Title lecture

The Investigation of the Tribocorrosion Properties of DLC coatings deposited on Ti6Al4V Alloys by CFUBMS

Authors

E. Arslan, Y. Totik, I. Efeoglu

Abstract

Various machine components produced from titanium alloys used in various industries are subject to a combination of electrochemical and mechanical effects. The science of surface transformations resulting from the interaction of mechanical loading and chemical reactions that occur between elements of a tribosystem exposed to corrosive environments is described as tribocorrosion. This research focus on tribocorrosion behaviour of Ti6Al4V alloys after coated by closed field unbalance magnetron sputtering (CFUBMS) at different coatings parameters. The structural analyses of the coatings were performed using XRD and SEM techniques. The hardness was measured using microhardness tester. Tribocorrosion experiments were performed in a pin on disk tribotester under electrochemical polarization in NaCl 1 wt. % solution.

Wolfgang Ensinger

Technische Universitaet Darmstadt, Department of Materials Science, Darmstadt, Germany

Title lecture

Nanofilms of a Surface-Near Platinum/Tantalum Alloy Formed by Ion Implantation for Reducing Hydrogen Embrittlement of Tantalum

Authors

W. Ensinger

Abstract

Tantalum is a highly chemically stable metal with extraordinarily good corrosion properties. It is therefore used as construction material for handling hot mineral acids. In contact with hot sulphuric acid, the dissolution of metal is acceptably low. However, as a side reaction hydrogen ions from the acid is being discharged, thus forming elemental hydrogen on the metal surface. The hydrogen atoms may diffuse into the tantalum lattice, react with the metal to form tantalum hydride, or even agglomerate into bubbles. Since the metal hydride is brittle and the process leads to build up of pressure and stress, the metal can fail mechanically. This reaction can be prevented when platinum is brought into contact with tantalum. For this purpose, platinum was ion implanted into the tantalum surface. A long-term immersion test in hot sulphuric acid combined with a mechanical test showed that the small amount of surface-alloyed platinum is sufficient to effectively protect the metal from embrittlement.

Yaiza González-García

Delft University of Technology, Department of Materials Science and Engineering, Delft, The Netherlands

Title lecture

Local electrochemical evaluation of self-healing coatings for corrosion protection of metals

Authors

Y. González-García, S.J. García, H.R. Fischer, A.E. Hughes, J.M.C. Mol

Abstract

In this work local electrochemical techniques are introduced as powerful and complentary techniques for the in-situ evaluation of self-healing systems applied for the protection of metals against corrosion. Scanning vibrating electrode technique (SVET) and scanning electrochemical microscopy (SECM) are employed for the evaluation of coatings with encapsulated self healing agents for the protection of aluminium alloys. SVET measurements allowed to in-situ monitor the corrosion processes taking place within a coating defect during immersion in chloride solution. On the other hand, SECM operating in redox competition mode allowed to monitor the evolution of the cathodic process at the defect which is the reduction of dissolved oxygen in solution. SVET and SECM results showed that the release of healing agent from the broken capsules during the damaging of the surface indeed leads to a hindering of the corrosion processes and therefore provide an effective protection of the metallic surface.

Kristina Kohlgrüber

University of Paderborn, Colloids & Coatings C&C/CTB, Paderborn, Germany

Title lecture

Surface modification of zinc particles - Application in a corrosion protection primer

Authors

Kristina Kohlgrüber, Oleg Jungmann, Wolfgang Bremser

Abstract

Weldable corrosion protection primers are state of the art in automotive industry. The disadvantage of this primer is the adhesion between matrix and zinc particles. At this interface water can access into the coating which leads to a reduction of corrosion protection. To ensure superior adhesion between the interfaces, zinc particles were modified. To modify the zinc particle various Triethoxysilanes were investigated. After hydrolysis of Triethoxysilanes, the zinc particle surfaces were modified with a Siloxane layer. Modifications were investigated by DRIFT spectroscopy, SEM and FIB. Silane layer thickness was determined by 50 nm. The coated zinc particles were incorporated into a primer. Characterization of the barrier effect of the primer was carried out by using electrochemical impedance spectroscopy and the water adsorption of the coating with and without modification of the zinc particles was compared. A visual assessment of the adhesion between matrix and modified zinc particle was carried out by freeze fracture electron microscopy.

Bahram Ramezanzadeh

Department of Polymer Engineering and Color Technology, Amirkabir University of Technology, Tehran, Iran

Title lecture

A study on the cathodic delamination and anticorrosion performance of an epoxy composite on the steel samples treated by Cr(VI) free conversion coatings

Authors

B.Ramezanzadeh, M.M. Attar, M. Farzam

Abstract

Attempts have been made to improve the adhesion and corrosion resistance of an epoxy coating on steel substreate using environmentally friendly conversion coatings (CCs). The steel substrates were treated by Cr(III) and Cr(VI) chemical treatments. The Cr(III) pre-treated samples were also post-treated by Co(II) and Ni(II) chemical treatments. The epoxy coating, reinforced with micro-ZnO particles, was applied on each pre-treated sample. Analytical techniques including SEM, EIS, cathodic disbanding and pull-off were utilized to evaluate the coating properties on each CC treated sample. It was found that the corrosion resistance and adhesion strength (dry adhesion) of the epoxy coating were superiorly improved on the pre-treated steel samples. The adhesion strength and corrosion resistance of the Cr(III) treated samples were considerably greater than those treated by Cr(VI). It was found that using Co(II) and Ni(II) post-treatments on the Cr(III) pre-treated samples caused significant increase in the adhesion strength and corrosion resistance of these samples. The cathodic disbonded area of the Cr(III)-Co(II) and Cr(III)-Ni(II) treated samples was considerably lower that those treated by Cr(III) and Cr(VI). It was also found that, due to the high corrosion resistance of the pigmented epoxy coating, the rate of disbonding and corrosion products creation beneath the coating were controlled by the interfacial adhesion bonds hydrolysis.

Functional Coatings

Guy Applerot

Department of Chemistry, Kanbar Laboratory for Nanomaterials, Institute of Nanotechnology and Advanced Materials, Bar-Ilan University, Ramat-Gan, Israel

Title lecture

Ultrasound radiation as a technique for the production of antibacterial nanocomposite textiles

Authors

G. Applerot, A. Irzh, I. Perelshtein, and A. Gedanken

Abstract

Ultrasound irradiation was applied both as a synthesis route as well as a "throwing stones" technique for coating textile fabrics (nylon, polyester and cotton) with various nanoparticles. The homogeneous distribution of the nanoparticles without any aggregation on the fabrics was demonstrated. The antibacterial activities of the fabric nanocomposite were tested against Escherichia coli (Gram negative) and Staphylococcus aureus (Gram positive) cultures. A significant bactericidal effect, even in a concentration <1% (by weight), could be detected.

Ersin Arslan

Erzurum College of Vocational, Ataturk University, Erzurum, Turkey

Title lecture

Comparison of structure and tribological properties of MoS2-Ti films deposited by biased-dc and pulsed-dc

Authors

E. Arslan, I. Efeoglu, Y. Totik

Abstract

A closed field unbalanced magnetron sputter (Teer-CFUBMS/550) system was used for the deposition of MoS2-Ti composite coatings on steel substrate (AISI D2) with using biased-dc and pulsed-dc. The tribological properties of MoS2-Ti coatings were characterized by pin-on-disc wear tester under atmospheric conditions. Structural analysis was pointed out using X-ray diffraction and SEM-EDS. The microstructure and chemical composition of MoS2-Ti films are very strongly influenced by the sputtering process conditions. While X-ray diffraction pattern of films deposited using pulsed-dc shows mainly (002) reflections, the films deposited by dc-bias exhibit random orientation being both (002) and (100) reflections. Tribological performance of the films deposited using both techniques were compared in view of both crystallographic orientation and Ti content.

Camille Carcouët

Laboratory of Materials and Interface Chemistry, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Eindhoven, The Netherlands

Title lecture

Synthetic approaches for raspberry-like particles leading to transparent superhydrophobic coatings

Authors

C. Carcouët, A.C.C. Esteves, R.A.T.M. van Benthem, G. de With

Abstract

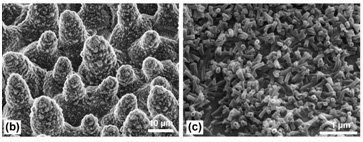

Superhydrophobic surfaces have attracted much interest in the last decades for both fundamental research and practical applications. The development of such surfaces has been mostly driven by the promise of self-cleaning properties of these coatings [1].

Although such surfaces are already widely present in nature, this property is still a challenge for synthetic coatings. The most famous example in nature is the Lotus leaf. Despite growing in muddy water, its leaves remain clean. When rainwater hits the leaves, the droplets roll off the surface, washing away any contaminations and dust.

Research has revealed that the self-cleaning property of Lotus leaves originates from the combination of micrometer-scale papillae and nanometer-scale wax tubules, together with the reduced adhesion between surfaces and particles. Their surface is usually labelled as hydrophobic [2]. Generally, a surface is called superhydrophobic if it is extremely difficult to wet due to a water contact angle larger than 150° and a low sliding angle (Figure 1).

Figure 1: SEM of a Lotus leaf: (left) image of the upper leaf showing the hierarchical surface structure of papillae (micro-sized) and wax tubules (nano-sized) and (right) wax tubules on the upper leaf [3].

For synthetic coatings, a dual-size roughness combined with low surface energy species appears to be essential to reach superhydrophobicity. A nature-inspired approach - christened the ´raspberry´ approach - has been scientifically developed, leading to man-made superhydrophobic surfaces [4]. In this method, the key to introduce well-controlled dual-size roughness involves the synthesis of raspberry-like inorganic silica particles (Figure 2).

Figure 2: Preparation of superhydrophobic films based on raspberry-like particles (left) and TEM picture of raspberry-like silica particles (right).

However, due to the large particle size, this superhydrophobic coating is not optically transparent. Hence, the first aim of this research is to develop a structure with sufficient hydrophobicity, as well as transparency. Thereafter, the aim is to further improve the scratch-resistance of the material.

The "raspberry" approach typically uses particle sizes in the order of the wavelength of visible light and therefore scattering occurs. Therefore, it is necessary to reduce the size of the particles to a much smaller scale. The inorganic silica particles were successfully synthesized within the targeted range, according to the Stöber method. However, this method leads to polydisperse particles. The use of basic amino acid monomers, such as lysine, in place of ammonia as catalyst in the hydrolysis-condensation reaction of tetraethyl orthosilicate (TEOS) has been reported to give narrower-sized distribution particles [5].

Herein, we present the successful synthesis of raspberry-like silica nanoparticles within the targeted range to achieve transparency. The two synthetic approaches, using either ammonia or lysine as catalyst, are also compared. The synthesized particles were characterized by DLS and IR Spectroscopy and their morphology was evaluated by SEM and TEM.

References

- Bhushan, B.; Jung, Y.C.; Koch, K., 2009, 25, 3240.

- Neinhuis, C.; Barthlott, W., Annals of Botany, 1997, 79, 667.

- Ensikat, H.; Ditsche-Kuru, P.; Neinhuis C.; Barthlott W., Beilstein Journal of Nanotechnology, 2011, 2, 152.

- Ming, W.; Wu, D.; van Benthem, R.; de With, G., Nano Letters, 2005, 5, 2298.

- Yokoi, T.; Karouji T.; Ohta S.; Kondo J.; Tatsumi T., Chemistry of Materials, 2010, 22, 3900.

Ismail Dogan Gunbas

Laboratory of Polymer Chemistry, Eindhoven University of Technology, Eindhoven, The Netherlands

Title lecture

Hydrophobic coating using Poly(dimethylsiloxane) (PDMS)-grafted polystyrene maleic anhydride (PSMA) copolymer on cotton fabric and washing durability

Authors

I.D. Gunbas, M.E.L. Wouters, R.A.T.M. van Benthem, C.E. Koning, B.A.J. Noordover

Abstract

A superhydrophobic surface is generally obtained by two criteria: a low surface energy and an appropriate surface roughness which result in water detaching from the surface at a low roll-off angle. Moreover, the washing durability of highly hydrophobic cotton fabric is crucial, as most textile fabrics would undergo repeated laundering during their lifetime. Poly(dimethylsiloxane) (PDMS) is an important inorganic polymer, as PDMS and PDMS-based materials are attractive for a variety of industrial applications because of their unique properties such as good thermal stability in air and a wide temperature range in which it can be used. PDMS was used in the textile water-repelency treatment because of its low surface energy and its high hydrophobicity [1]. However, PDMS has a poor adhesion to the textile surfaces [2] and accordingly can easily be removed by cleaning or washing procedures. Many researchers have reported the introduction of PDMS into polymer materials to improve flexibility and to provide a linkage of PDMS to the textile surface [3-5]. Our aim is to graft PDMS-NH2 onto the polymer main chain of an alternating styrene-maleic anhydride copolymer (PSMA) by partial imidization. For this purpose four different PDMS-grafted PSMA copolymers were prepared by partial imidization of the initial anhydrides groups in PSMA and used to improve washing durability of hydrophobic cotton fabric finished by polymer impregnation method. The wettability of treated fabrics was characterized by water contact angle measurements. This study demonstrated that the surface treatment using PDMS-grafted PSMA copolymers is a promising alternative for achieving durable hydrophobic fabrics.

References

- Wada, S. S., JP), Honda, Kayoko (Settu, JP), Kunimasa, Keiko (Settu, JP), Imoto, Katsuhiko (Settu, JP). Daikin Industries, Ltd. (Osaka, JP), United States: 2004.

- Chen, W.-H.; Chen, P.-C.; Wang, S.-C.; Yeh, J.-T.; Huang, C.-Y.; Chen, K.-N., Journal of Polymer Research 16, 601 2009.

- Furukawa, N.; Yuasa, M.; Kimura, Y., Journal of Polymer Science, Part A: Polymer Chemistry 36, 2237 1998.

- Nakata, S.; Kawata, M.; Kakimoto, M.-A.; Imai, Y., Journal of Polymer Science Part A: Polymer Chemistry 31, 3425 1993.

- Ochi, M.; Takemiya, K.; Kiyohara, O.; Nakanishi, T., Polymer 39, 725 1998.

Tae Woong Kang

School of Nano & Advanced Materials Engineering, Changwon National University, Changwon, Kyungnam, Korea

Title lecture

Thickness effect on thermal properties of thermal barrier coatings with thermal exposure

Authors

Presenting T.W. Kang, Co-authors S.W. Myoung, K.S. Song, Z. Lu, Y.G. Jung, U. Paik

Abstract

The microstructure related to the thickness of TBC and their thermal properties have been investigated with a specific attention to defect species as well as to its morphology with the thermal exposure time. In order to investigate the thermal properties of TBC related to the microstructural evolution, TBCs with different thicknesses of 600 and 2000 μm were prepared by the APS and the thermal exposure tests were performed at 950 °C in a furnace with a dwell time of 100 h up to 500 h. The thickness of thermally grown oxide (TGO) layer in the TBC with 2000 μm is thinner than that with 600 μm. Also, the TBC with 2000 μm thickness is more efficient in improving the oxidation resistance in the bond coat than that with 600 mm thickness. However, the interfacial stability of the TBC with 2000 μm thickness is significantly severe than that with 600 μm thickness, showing relatively longer cracks. These results imply that the interfacial stability in the thick TBC should be improved for the reliability and lifetime performance of components in gas turbines, even though they show the better oxidation resistance and thinner TGO thickenss.

Mohsen Mohseni

Associate Professor, Department of Polymer Engineering and Color Technology, Amirkabir University of Technology, Tehran, Iran

Title lecture

Self-cleaning Automotive Clear Coats; Part 1: Films Behavior against Bilogical Degradation

Authors

H.Yari, M.Mohseni, A.Mohammad rabea, B.Ramezanzadeh.

Abstract

Biological degradation of automotive coatings is a real concern for car industries. We have recently showed that surface chemistry of automotive clear coats is highly affecting their biodegradability. The work presented here aims at studying the surface chemistry and mechanical properties of an acrylic melamine clear coat containing a siliconized additive. The hydrophobic films obtained were then investigated for their easy cleanability and non-stick behavior with respect to their resistance against hydrolytic and biologically-induced degradations. Variations in the surface and bulk chemical structures, as well as thermo-mechanical characteristics of the clear coats at different concentarions of the additive were monitored utilizing contact angle measurements, ATR-FTIR spectroscopy and DMTA analysis. It was revealed that even at low loadings of additive it could migrate to the surface, leading to hydrophobic films with very low surface energies having contact angle exceeding 105 degrees. In addition, it was found that the functional additive was covalently entangled to the acrylic/melamine chains through its hydroxyl groups as revealed by ATR-FTIR studies. Such modifications had a positive impact on thermo-mechanical properties of siliconized films by increasing Tg from 79 to 86 °C.

Jörg Ressel

University of Paderborn, Coatings and Colloids C&C/CTB, Paderborn, Germany

Title lecture

Ultra Low Friction Coatings via Polyamidimid-Polydimethylsiloxane-Block-Copolymers

Authors

Jörg Ressel, Daniel Briesenick, Wolfgang Bremser

Abstract

Friction of polymeric surfaces is a limiting factor to several industrial processes. Therefore lubricating additives in the form of particles, waxes or liquids are conventionally used to achieve low friction coefficients and reduce wear. Insulating coatings or wire enamels need to show uniformly constant, low friction without running in. Also required attributes are high temperature resistance and flexibility. Therefore Polyamidimid magnet wires are treated with solvent based waxes in additional application processes. Siloxane brush model surfaces have already been used to create ultra low friction surfaces [1, 2, 3], suggesting hydrodynamic lubrication. Nonreactive PDMS Additives are widely used in commercial applications.

In this work we focused on Polyamidimid--Polydimethylsiloxane-Block-Copolymers of varying structure, PDMS segment length and PAI to PDMS ratio. Coatings thereof show characteristic surface patterning with "liquid like" covalent bond PDMS phase separations beside considerably lowered friction, particularly with regard to the polymer polymer contact.

AFM revealed self patterned anisotropic surfaces of a polar matrix and non polar areas. Nano mechanical AFM also revealed high differences in mechanical characteristics: rigid polar PAI matrix and soft, "liquid like" PDMS phase separations. SEM and EDX surface characterization identified PAI matrix and PDMS rich phases.

Presently our efforts concentrate on self patterning periodicity control by choosing PAI-PDMS-block-co-polymer structure and concentration. Beside this we are introducing PDMS micro gel particles into self patterned coatings to further improve polymer steel sliding performance.

References

- A. Casoli, M. Brendl´e, J. Schultz, P. Auroy and G. Reiter, Tribology Letters 8 (2000) 249-253

- Tomohiro Tada, Daisaku Kaneko, Jian Ping Gong, Tatsuo Kaneko and Yoshihito Osada, Tribology Letters, Vol. 17, No. 3, October 2004

- S. Bistac and A. Galliano, Tribology Letters, Vol. 18, No. 1, January 2005

Jianfang Wang

Department of Chemistry and Biology, College of Science, National University of Defense Technology, Changsha, P. R. China

Title lecture

Effect of Surface Microstructure on Hydrophobicity of Coating

Authors

Jianfang Wang, Xiaozhou Tian, Hui Zhu, Yin Long, Yuanyang Lai

Abstract

Since more and more attention was paid to environment protection in the whole world, the antifouling coatings with non-toxic and non-releasing get abroad favor. In this paper, coating adopting nano-particles SiO2 ranging from 1%~7% was in-situ polymerized with low surface energy polymer and brought on good combination. Surface microstructure was built automatically when painting film. Copper surface microstructure was build by Chemical etching method and then modified by low surface energy as contrast. The contact angle and the peel strength of simulative bio-gooey were studied. The results showed that the hydrophobic of polymer with low surface energy was remarkably affected by surface microstructure, and worked to antifouling property further. The hydrophobic and antifouling property of the surface were effectively improved by mimicking the micro-nano secondary structure of lotus leaf while furthest reducing the contact area with attachment. The coating added 5% SiO2 nano-particles which had the maximum contact angle and the minimum peel strength showed surface microstructure as micro-nano secondary structure like lotus leaf. Copper sheet which was etched 15 minutes and disposed with low surface energy material showed fine surface microstructure with obvious gradation, maximum contact angle and minimum peel strength.

Hybrid Materials and Nanocomposites

Carola Esposito Corcione

Dipartimento di Ingegneria dell´Innovazione, Università del Salento, Lecce, Italy

Title lecture

UV-cured polymer-boehmite nanocomposite as protective coatings for wood-based elements

Authors

C. Esposito Corcione, M. Frigione

Abstract

An organo-modified Boehmite (OMB) was used to prepare nanocomposite UV - curing coatings, based on an innovative photopolymerizable siloxane-modified acrylic formulation, for possible use as protective coatings. 3 wt.% of the nanofiller was dispersed into the resins in the presence of a proper photoinitiator for UV curing. Different amounts of a silane coupling agent were added to the mixture in order to enhance the compatibility between the nanofiller and the siloxane-modified acrylic formulation. The kinetics of the radical photopolymerization reaction, induced by UV radiations was studied by photo-calorimetric analysis. The formulations, coated on a glass substrate, were photocured by using a medium pressure Hg UV lamp. On the coatings photo-polymerized in air were measured: gel content, transparency, scratch and surface hardness. The impact of chemical treatments with novel organic photocurable nanocomposites on the preservation of walnut wood elements was evaluated. The water absorption behaviour of walnut wood treated samples species was studied.

Eun-Hee Kim

* School of Nano and Advanced Materials Engineering, Changwon National University, Changwon, Kyungnam, Republic of Korea

Title lecture

Fabrication and mechanical properties of Al2O3 based multi-phase composite through surface charge

Authors

Presenting E. H. Kim, Co-author W. R. Lee, Co-author J. S. Kim, Co-author Y. G. Jung.

Abstract

The bi-reinforcement phases of multi-walled carbon nanotubes (MWCNTs) and titanium carbide (TiC) have been incorporated into the alumina (Al2O3) matrix prepared with aluminum hydroxide (Al(OH)3), to improve the mechanical and functional properties of the Al2O3 matrix. The reinforcement phases have been mixed using its surface charges for the uniform dispersion into the Al2O3 matrix, as functions of the content of reinforcement phase and the potential hydrogen (pH) of suspension. MWCNTs were purified and modified by an acid to enhance their dispersibility in an aqueous solution. The modified MWCNTs were added in the TiC suspension with the pH 7. The TiC-coated MWCNTs solution was filtered, dried, and heat-treated at 500 °C. Then, the prepared TiC-coated MWCNTs were mixed with the Al(OH)3 solution with the pH 2 and filtered at room temperature. The prepared multi-phase composites show higher mechanical properties than pure Al2O3 due to the inhibition of grain growth by the reinforcement phases and the higher mechanical properties of the reinforcement phases. However, the mechanical properties are decreased beyond the optimum content of reinforcement phases, because of the heterogeneous aggregation of reinforcement phases.

Tiago Menezes

LAPEC - Metallurgy Department, PPGEM, UFRGS, Porto Alegre, Brazil

Title lecture

Zinc-talc composite coatings post-treated with γ-methacryloxypropyl-trimethoxysilane and tetraethoxysilane with cerium salt addition

Authors

Menezes T.L., Oliveira C.T., Muller, I.L., Malfatti C.F.

Abstract

The electrochemical behavior of zinc-talc composite coatings with and without hybrid xerogel film post-treatment was studied and compared. The composite coatings were obtained by electrodeposition of zinc with talc particles incorporation into the metallic matrix. The hybrid xerogel films were obtained by a dip-coating technique process from the sol containing methacryloxypropyl-trimethoxysilane and tetraethoxysilane silane precursors, with cerium salts addition. The electrochemical characterization was carried out by EIS tests and OCP measurement along the immersion time. The morphology of the coatings was evaluated by SEM. The EIS results showed different corrosion phenomena after treatment with hybrid xerogel films. The resistance related to the presence of the hybrid xerogel film (Rsi), and the formation of a corrosion product of cerium/zinc (Rzco) acted jointly to protect the zinc coating, inserting a resistance to the corrosion, which result of the sum of both was denominated Rt.

Tiago Menezes

LAPEC - Metallurgy Department, PPGEM, UFRGS, Porto Alegre, Brazil

Title lecture

γ-methacryloxypropyl-trimethoxysilane and tetraethoxysilane silane precursors : applied as a post-treatment of ZnNi coatings

Authors

T.L. Menezes, Kunst S.R., J-P Bonino, F. Ansart, C. Salacruch, C. T. Oliveira, C.F. Malfatti

Abstract

To avoid the corrosion process, zinc coatings are submitted to a treatment employing conversion coatings. The most popular and effective conversion process to produce a protective layer is based on the immersion of the alloy in a bath containing chromate ions. Due to the Cr(VI) toxicity, non-toxic alternatives have been developed. Among the possible alternatives, the use of hybrid xerogel has shown promising results. In this work, a system constituted by a hybrid xerogel coating on zinc-nickel electrodeposits was studied to the corrosion protection of steel substrate. The hybrid xerogel coating were obtained by dip-coating process in a sol constituted with silane precursors as γ-methacryloxypropyl-trimethoxysilane (MAP), tetraethoxysilane (TEOS) and cerium salts. The electrochemical measurements showed that ZnNi/ hybrid xerogel coating systems have a better electrochemical performance compared to Zn-Ni coating, but the corrosion rate was also affected by the withdrawal speed of substrates from the sol.

Interfaces and Adhesion

Mohsen Mohseni

Department of Polymer Eng. And Color Tech, Amirkabir University of Technology ,Iran

Title lecture

Quantifying the Interfacial Interaction of Various Silane Treated Nano Silicas with A Polyurethane Coating Using Tensile Strength and Dynamic Mechanical Thermal Analysis Experiments

Authors

M. Rostami, M. Mohseni, Z. Ranjbar

Abstract

Nano silica is widely used in clear polymeric coatings mainly due to its low refractive index, moderate hardness and insulativity. Presence of numerous hydroxyl groups at its surface makes this particle hydrophilic in nature. Silane coupling agents are usually used to impart hydrophobicity and also chemical reactivity to nano silica. The extent of interfacial interaction of treated silica with the matrix, depends mainly on the chemistry of the silane grafted particle. In the present study attempts have been made to quantitatively calculate the interfacial adhesion of two silane treated nano silicas having amino and epoxy functionalities in a polyurethane matrix. To this end, a pristine nano silica was first surface treated with amino propyltrimethoxy silane and glycidoxy propyl trimethoxy silane at different conditions. To study the interfacial interaction of treated nano silica, differential mechanical thermal analysis and tensile experiment were conducted on variously loaded polyurethane with treated silica. Using previously reported semi empirical mathematical models describing the relationship of mechanical attributes of these tests to the strength of interface, the values of parameter "B", known as "interfacial bonding constant" were obtained for each type of silica. These were then used together with the results of nanoindentation experiments to discuss the viscoelastic behavior of the interface. It was shown that amino and epoxy silane grafted nano silicas behaved differently. Amino functional silane increased the strength of the interaction considerably. While the polyurethane containing non-treated silica represented a plastic behavior, the treated ones revealed an elastic characteristic. The elasticity of polyurethane loaded with amino treated silica showed to be greater compared with epoxy silane grafted silica.

Xiaolong Zhang

TNO, Den Helder, The Netherlands

Title lecture

Influence of surface preparation on the corrosion performance of epoxy coatings for ship ballast tank

Authors

X.Zhang, S.J. Buter, G.M. Ferrari

Abstract

The surface preparation has influence on the adhesion and corrosion performance for the epoxy coatings used in ship ballast tank. The international Maritime Organization (IMO) has adopted a Performance Standard for Protective Coatings (PSPC) on the surface preparation. However, there is still dispute on the surface condition criteria for the coating systems applied to the ship ballast tanks due to the lack of technical justification. In this investigation, the corrosion performance for epoxy coatings applied to different surface conditions has been studied. Ship steel substrates were prepared in different conditions, such as grit blasted to Sa2½, with shop-primer, with primer and outdoor aged, the primer surface containing salts in different amounts up to 100 mg/m2. The thickness of the epoxy coating used for laboratory exposure tests is about 150 micrometers. The exposure tests were performed by continuous immersion in the seawater at room temperature and in wet/dry cyclical test at 20 and 40 °C. The corrosion resistance of these coated specimens was measured by electrochemical impedance spectroscopy (EIS) as a function of time. The adhesion of the coatings has been measured before and after exposure to seawater tests. The surface structures of the specimens with shop primer were studied using SEM-EDS The results show that the coatings on the surfaces with soluble salt 100 mg/m2 has indeed lower corrosion resistance and lower adhesion than on the other surfaces. The corrosion performance of the coatings on the surfaces outdoor aged is better than on the surfaces blasted. The results and the mechanism will be discussed in the paper.

Material Properties

Jothi Sudagar

Department of Materials Science and Engineering, Nanling campus, Jilin University, Changchun, China

Title lecture

The Performance of surfactant on the surface characteristics of electroless on magnesium alloy

Authors

Jothi sudagar, Rasu Elansezhian, Jianshe Lian

Abstract

Magnesium and its alloys corrode rapidly in the electrolyte bath. Surfactants while used extensively as surface active agents in the electrolyte bath, have been little studied on magnesium surfaces. The influence of surfactants cetyltrimethyl ammonium bromide and sodium lyrul sulphate on the surface properties such as roughness, morphology and topography of electroless Ni-P deposits on magnesium alloy was studied in this paper. The study reveals that the surfactants had significant influence on the surface roughness, surface morphology and surface topography. In addition, it had marginal effect on the microhardness by addition of surfactants. Electroless coatings with addition of surfactants produce a smooth surface and average roughness (Ra) value is 0.822 μm for CTAB and 1.218 μm for SLS, which is far less than the value of without surfact addition 3.978 μm. There was a significant improvement in the rate of deposition. However, the surfactants influence reached maximum at the critical micelle concentration (CMC) above this value it stablised. Surface morphology and surface topography in the coating was analysed by SEM and AFM. The complete experimental details and their analysis are reported in this paper.

Ying-Chieh Lee

Department of Materials Engineering National Pingtung University of Technology and science, Pingtung, Taiwan, R.O.C

Title lecture

The Effect of Mg Dopant on Microstructure and Phase Transformation of ZnTiO3 Thin Films

Authors

Ying-Chieh Lee, Yun-Lin Huang, Po-Shun Chen

Abstract

Mg doped zinc titanate (ZnTiO3) films were prepared using RF magnetron sputtering. Subsequent annealing of the as-deposited films were performed at temperatures ranging from 600 to 900 °C. It was found that the as-deposited films was amorphous and contained 2.77 at.% Mg. This was further confirmed by the onset of crystallization that took place at annealing temperatures 600 °C. The results showed that signle Zn2Ti3O8, phase was existed at 600 °C. When annealing is at 700 °C, the results revealed that mainly hexagonal ZnTiO3 phase accompanying Zn2Ti3O8 minor phases were observed. When annealing is at 900 °C, the results showed that signle hexagonal ZnTiO3 phase stably was existed. Unlike pure zinc titanates films, this result shows that the ZnTiO3 phase can be stable at 900 °C. It means there is no decomposition from hexagonal ZnTiO3 to cubic Zn2TiO4 and rutile TiO2 took place with a further increase in temperature to 900 °C. This result indicates that Mg dopants in zinc titanates thin film leads to ZnTiO3 phase existence at higher temperatures. Moreover, the twins are observed for Mg doped zinc titanates thin films annealed at 800 °C. It could be explained that the Zn2+ ions are substituted by Mg2+ ions into ilmenite ABO3 structure, it will create lattice strain due to ion size effect.

Photochemistry

Wu Menghua

Dipartimento di Chimica, Materiali e Ingegneria Chimica, Politecnico di Milano, Milano,Italy.

Title lecture

UV-resistant amorphous fluorinated coating for anodized titanium surfaces

Authors

Wu Menghua,Walter Navarrini, Maria Vittoria Diamanti, Maurizio Sansotera, Federico Persico, Luca Magagnin, Stefano Radice

Abstract

A high molecular weight copolymer of tetrafluoroethylene and perfluoro-4-trifluoromethoxy-1,3-dioxole (Hyflon® AD60), and two perfluoropolyether containing ammonium phosphate or triethoxysilane functionalities, Fluorolink® F10 and Fluorolink® S10 respectively, have been evaluated as protective coatings that can be easily applied on anodized titanium surfaces. Based on CIELab model, spectrophotometric analysis have been made to quantify chromatic variations of substrates after the application of fluorinated coatings. Water and n-dodecane contact angle measurements have been done by using the sessile drop method for both bare and coated surfaces in order to determine the hydrophobic and oleophobic properties of the coatings. The UV-stability of coatings have been studied by observing the variation of water contact angles and by FT-IR analyses on coated substrates before and after UV irradiation at regular time intervals. The thickness of the fluorinated films have been measured by ellipsometry and by weight evaluation. Preliminary adhesion tests between films and substrate as well as their soiling resistance with castor oil have been investigated. Among the above three fluorinated polymers, we observed that the high Tg amorphous transparent Hyflon® AD60 revealed a good adhesion on the anodized titanium substrate, no evident modification of the sample original color, and in addition it conferred both hydrophobicity and oleophobicity to the substrate, more over resulted in a good UV resistance.