Speakers COSI 2011

- Anwar Ahniyaz*,YKI, Institute for Surface Chemistry, Synthesis and surface modification of functional nanoparticles to improve coating performance

- Dr. Ingo Alig, Deutsches Kunststoff-Institut, Darmstadt, Germany Monitoring of Photopolymerization Kinetics and Network Formation by Ultrasonic Reflectometry and Near-Infrared Spectroscopy

- Audrée Andersen, BASF Coatings GmbH, Muenster, Germany, Adhesion of Coatings, an Interfacial Challenge

- Guy Applerot, Bar Ilan University, Department of Chemistry, Kanbar Laboratory for Nanomaterials, Institute of Nanotechnology and Advanced Materials, Ramat-Gan, Israel, ZnO nanoparticles coatings for antibacterial and medical applications

- Jamil Baghdachi*, Coatings Research Institute, Eastern Michigan University, Ypsilanti, MI, USA, Investigation, design and development of self-stratifying coatings

- Prof.dr. Massimiliano Barletta, Dipartimento di Ingegneria Meccanica, Università degli Studi di Roma Tor Vergata, Roma, ITALY, Micro-scratch deformation contributions of epoxy-polyester films deposited on substrates after different surface treatments

- Victor Baukh, Department of Applied Physics, Eindhoven University of Technology, Eindhoven, The Netherlands, Water transport in multilayer organic coatings

- Prof. Dr. Gordon Bierwagen, North Dakota State University, Fargo, ND, USA, Incorporation of Conductive Fillers into Mg-rich Primers

- Gabriela Ciobanu, Gheorghe Asachi" Technical University of Iasi, Faculty of Chemical Engineering and Environmental Protection, Iasi, Romani, The effect of vitamins to hydroxyapatite growth on porous polyurethane substrate

- Prof.Dr. Martien Cohen Stuart*, Laboratory of Physical Chemistry and Colloid Science, Department of Agrotechnology and foodsciences, Wageningen University, Wageningen, The Netherlands, Chemistry and physics of associative thickeners

- Prof.Dr. Stuart Croll, North Dakota State University, Fargo, USA, The effect of pigments on the long term durability of artists´ oil paint

- Dr. Dirk Eierhoff, BASF Coatings GmbH, Muenster, Germany, On Cloud Nine - A Potential Evaluation Tool for Local Fluctuations of the Viewing Angle Dependent Brightness of Automotive Effect Coatings

- Jacco Eversdijk, TNO Science and Industry, Eindhoven, The Netherlands, Development of a biocide containing nano-clay composite for prolonged antifungal activity

- Kostadinka A. Gesheva, Central Laboratory of Solar Energy and New Energy Sources - Bulgarian Academy of Sciences, Bulgaria Transition metal oxide films: Technology and "smart windows" electrochromic device perfomance

- Jerneja Godnjavec, Center of Excellence for Polymer Materials and Technologies, Ljubljana, Slovenia, Polyhedral oligomeric silsesquioxanes as titanium dioxide surface modifiers for transparent acrylic UV blocking hybrid coating

- Gustavo L. Guerriero, Structural Integrity, Faculty of Aerospace Engineering, Delft University of Technology, Delft, The Netherlands, Mechanical properties of Liquid Crystalline Thermosetting Coatings

- Yong He, School of Chemistry and Chemical Engineering, South China University of Technology, Guangzhou, China, A Recycling Model of Excess 2, 4-and 2, 6-Toluene Diisocyanate in the Preparing of Polyurethane Prepolymer

- Anthony E. Hughes, Commonwealth Scientific and Industrial Research Organisation, Division of Materials Science and Engineering, Clayton, Australia, Using X-ray Tomography, PALS and Raman Spectroscopy to Characterisation Inhibitors in Epoxy Coatings

- Alexander Irzh, Department of Chemistry and Kanbar Laboratory for Nanomaterials at the Bar-Ilan University Center for Advanced Materials and Nanotechnology, Bar-Ilan University, Ramat-Gan, Israel, Super-fast deposition of transparent super-hydrophobic layers on various surfaces using microwave plasma

- Alexandros Kakaroglou, Vrije Universiteit Brussel (VUB), Research Group of Electrochemical and Surface Engineering (META), Brussel, Belgium, Characterization of plasma polymerized poly (allyl methacrylate) coatings

- Prof.Dr. Andreas Kandelbauer, School of Applied Chemistry, Reutlingen University, Reutlingen, Germany / Department of Wood Science and Technology, University of Natural Resources and Life Sciences, Vienna, Austria, Photocrosslinkable vegetable oil modified resin for fiber reinforced composite and wood surface coating application

- Cristine Y.W. Lin, School of Materials Science and Engineering, University of New South Wales, Sydney, NSW, Australia, Mn-Doped Titania Thin Films Prepared by Spin Coating

- Mohsen Mohseni, Department of Polymer Engineering and Color Technology, Amirkabir University of Technology, Iran, Structural and Morphological Studies of Scratch Resistant Sol-Gel Based UV Cured Nano Composite Films on Polycabonate

- Thibault Muselle, Vrije Universiteit Brussel, Group of Electrochemical and Surface Engineering, Brussels, Belgium, Multiple action self-healing coatings for the corrosion protection of metals

- Mark Nichols, Ford Motor Company, Dearborn, MI, USA, A New Approach to Anticipating Florida Exposure Results

- Dr. Harald Oehler, Deutsches Kunststoff-Istitut, Darmstadt, Germany, Investigation of delamination mechanisms in coatings by scanning acoustic microscopy

- Siriwan Phattanarudee, Department of Imaging Science and Printing Technology, Faculty of Science, Chulalongkorn University, Bangkok, Thailand, Preparation of Biodegradable Nanocomposite Emulsions

- Claudia Philipp, Fraunhofer Institute for Wood Research, Wilhelm-Klauditz-Institut (WKI), Braunschweig, Germany, Waterborne polyurethane wood coatings based on rapeseed fatty acid methyl esters

- Cristoph Regula, Fraunhofer Institute for Manufacturing Technology and Applied Materials Research, Bremen, Germany, Corrosion protection of metal surfaces by atmospheric pressure plasma jet treatment

- Nadine Tenn, Laboratoire Polymères Biopolyméres Surfaces, Université de Rouen, Mont Saint Aignan Cedex, France, Water barrier properties of plasma treated EVOH and PLA films

- Russel J. Varley, CSIRO Materials Science and Engineeing, Clayton South, Australia, Investigation of Factors Impacting the In-Service Degradation of Aerospace Coatings

- Polina Volovitch, Ecole nationale supérieure de chimie de Paris (ENSCP): Paris, France, New approach for measuring reactivity and degradation of complex surfaces: a review of recent results

- Andriy Voronov*, Coatings and Polymeric Materials, North Dakota State University, Fargo, ND, USA, Interfacial behavior of self-assembled micellar nanostructures from stimuli-invertible macromolecule

- Hirotsugu Yasuda, Department of Chemical Engineering, University of Missouri, Columbia, MO, USA, Green System Approach Interface Engineering for Coating of Metals; DC Plasma Polymerization and Magneto-Plasma Polymerization

- * At the COSI conference are two kinds of speakers: invited speakers and regular speakers. Invited speakers have been put forward by one or more of the committee members and are exempted from the paper selection procedure. Invited speakers are still obliged like the committee members to pay the full fee. Regular speakers have submitted a paper to be considered for presentation by the committee members. Regular speakers will be informed of their selection in February 2011. They also are obliged to pay the full fee. COSI only supports reduced fees for students if they either present a poster or give a lecture. Note: There is only a total of 34 lecture spaces of wich ~10 are reseverd for invited speakers.

Anwar Ahniyaz

YKI, Institute for Surface Chemistry

Title lecture

Synthesis and surface modification of functional nanoparticles to improve coating performance

Authors

Anwar Ahniyaz,* Marie Sjoberg, Anders Larsson

Abstract

It is well-known that addition of a small amount of inorganic nanoparticle into the traditional coating formulation, can improve coating performance significantly. In order to maximize these 'NANO' effects, inorganic nanoparticles must be well-dispersed in organic matrix and suitable chemistry must be established between nanoparticle and organic binders.

However, due to the high surface energy of nanoparticles it is rather difficult to keep nanoparticles separate from each other to prevent their aggregations in dispersion. Moreover, to be able to use the nanoparticle in industrial coating, dispersion must meet a certain criteria. Compatibilization of inorganic nanoparticle dispersion with the specific binder system must be further studied to achieve decent storage stability of new coating formulation.

Most importantly, the successful application of nanoparticle in a desired coating system depends on our ability to understand the surface chemistry between the nanoparticle and the chosen binder system. Surface chemistry plays a significant role not only in synthesis, stabilization, and dispersion of inorganic nanoparticles, but also their compatibilization with a chosen binder systems.

In this presentation, I will discuss the importance of surface chemistry in the synthesis, surface modification, and dispersion of inorganic nanoparticles to achieve optimal coating performance. I will also give two application examples, UV protective coating for wood, 1 and corrosion protective coating for C-steel, 2 where we are able to improve the coating performance significantly by incorporating a few percent well-dispersed inorganic nanoparticles into these traditional coating formulations.

References

- WOODLIFE (FP7, NMP-2009-1.2-2: Extended service-life and improved properties of wood products through the use of functional nanoparticles in clear coating and adhesive systems)

- 2. STEELCOAT (FP7, NMP-2010-1.2-2: Development of green anticorrosion coatings for steel protection based on environmentally friendly nanoparticles and conducting polymers).

Dr. Ingo Alig

Deutsches Kunststoff-Institut, Darmstadt, Germany

Title lecture

Monitoring of Photopolymerization Kinetics and Network Formation by Ultrasonic Reflectometry and Near-Infrared Spectroscopy

Authors

Ingo Alig, Suman Agarwal, Dirk Lellinger, Harald Oehler, Katja Heymann and Tom Scherzer

Abstract

The kinetics of photopolymerization processes is studied by a combined ultrasonic (US) reflectometry [1] and NIR spectroscopy [2]. The increase of complex dynamic shear modulus and conversion can be measured simultaneously and in situ for the same piece of sample. This provides a novel opportunity to study the time-dependence of the dynamic shear modulus on the chemical conversion of the polymer in situ during polymerization [3]. US reflectometry has a high acquisition rate of more than 100 data points per second and NIR spectrometer provided with a fast array detector can record 30 data points per second. This allows us to study the photopolymerization kinetics in a time frame of milliseconds.

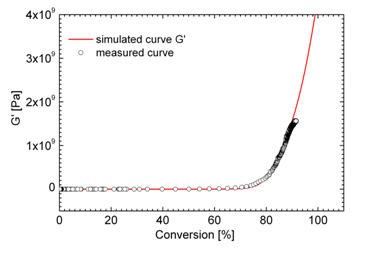

This method has been applied to study the photopolymerization kinetics of different acrylates. The influence of various constituents like photoinitiator, macromonomer (reactive diluent) and nanofiller on the curing kinetics of acrylates has been studied. From the conversion-time and modulus-time curves information on the relation between chemical reaction kinetics and rheological/mechanical properties can be deduced. The measurements provide information on the transition between "light" and "dark reaction phase" and on the onset of the diffusion controlled reaction regime. The combined modulus-conversion curves (Fig. 1) show reaction induced vitrification of the sample, which leads to down slowing of the chemical reaction ("effect of negative feed back").

Figure 1: Development of shear modulus during curing depending on chemical conversion. The plot shows the measured data and the simulated curve based on a physical model [3].

References

- I. Alig, D. Lellinger, J. Sulimma, S.Tadjbakhsch, Rev. Sci. Instrum. 68 (1997) 1536.

- I. Alig I, H. Oehler, D. Lellinger, S. Tadjbach, Progr. Org. Coatings. 58 (2007) 200.

- I. Alig, P.A.M. Steeman, D. Lellinger; A.A. Dias, D. Wiencke, Progr. Org. Coatings. 55 (2006) 88.

Audrée Andersen

BASF Coatings GmbH, Muenster, Germany

Title lecture

Adhesion of Coatings, an Interfacial Challenge

Authors

A. Andersen

Abstract

In the field of coatings for automobile industry, adhesion remains a crucial aspect which influences greatly the performance of a product. Pre-treatment conditions of the substrate, chemistry of the formulation or ageing conditions are all examples of parameters which influence greatly interfacial interactions, and therefore the adhesion performance. The industrial experience shows that even if many parameters have been improved over the last decades, interfacial adhesion still remains challenging.

Gaining an understanding on the nature of an adhesion failure as well as on the related mechanisms facilitates the development of sustainable solutions. In this sense, an effort has been given to combine different surface sensitive analytical methods in order to create a picture of interfacial chemical and mechanical interactions which lead to adhesion failure.

With the help of, for instance, ToF-SiMS, rheological methods, infrared spectroscopy or nanoindentation, it was possible to define the cause of adhesion failure in different paint build-ups of the automobile industry. We could furthermore shed some light on various aspects of the adhesion mechanisms occurring in this field. Example coming from our daily work will be presented.

Guy Applerot

Bar Ilan University, Department of Chemistry, Kanbar Laboratory for Nanomaterials, Institute of Nanotechnology and Advanced Materials, Ramat-Gan, Israel,

Title lecture

ZnO nanoparticles coatings for antibacterial and medical applications

Authors

G. Applerot, A. Irzh, J. Lellouche, A. Gedanken

Abstract

Zinc oxide (ZnO) nanoparticles were synthesized and deposited on the surface of glass slides-uncoated and coated with Parylene layer using three methods: ultrasound, microwave and microwave plasma irradiation. The structure and morphology of the nanoparticles were studied as a function of the synthesis time and the coating routes. The deposited film was analyzed using characterization methods such as XRD, HR-SEM, EDS, AFM, RBS and optical spectroscopy. Zinc oxide submicron and nanosized crystals with an average diameter of ~100 nm strongly adhered to the glass surface. These methods are fast, simple, convenient, economical, and environmentally friendly. The antibacterial activities of the ZnO–glass composites were tested against Escherichia coli (Gram negative) and Staphylococcus aureus (Gram positive) strains.

Jamil Baghdachi

Coatings Research Institute, Eastern Michigan University, Ypsilanti, MI, USA

Title lecture

Investigation, design and development of self-stratifying coatings

Authors

J. Baghdachi, H. Perez, Punthip Talapatcharoenkit.

Abstract

Certain coating applications such as automotive and aerospace require a combination of basecoat and clearcoat. These multilayered systems require a complex application and curing procedure. It would be desirable to reduce the number of layers to a minimum while providing the same or better overall performance that current systems provide. In this paper we report the design and development of thermosetting polyurethane coatings that self-stratify to two distinct phases upon application and cure. Prototype pigmented systems were applied and cured and were characterized by FTIR, SEM/EDX and were evaluated using standard coating test methods. Microtome and adhesion studies verified that the stratified layers were presumably linked through a urethane linkage. This finding may be taken as an evidence of multi-phase, preferential reactivity, mass transport, and surface tension gradient hypothesis as the basis of the above self-stratification phenomenon.

Prof.Dr. Massimiliano Barletta

Dipartimento di Ingegneria Meccanica, Università degli Studi di Roma Tor Vergata, Roma, ITALY

Title lecture

Micro-scratch deformation contributions of epoxy-polyester films deposited on substrates after different surface treatments

Authors

M. Barletta

Abstract

The present investigation has the aim to investigate the importance of the substrate or the sub-layer characteristics on the deformation response in scratch tests of epoxy-polyester films. A comparative study of the scratch deformation behaviour of films deposited on micro and macro corrugate rigid substrates and on 'soft' silicon sub-layers is made by combining morphological examinations by electron microscopy and scratch deformation parameters by CLA profilometry. The influence of the applied loads, the speeds, the contact geometries, and the test modes on the residual deformation patterns were analysed.

Victor Baukh

Department of Applied Physics, Eindhoven University of Technology, Eindhoven, The Netherlands

Title lecture

Water transport in multilayer organic coatings

Authors

V. Baukh, H. P. Huinink, O.C.G. Adan, S.J.F. Erich, L.G.J. van der Ven

Abstract

Water uptake by multilayer films plays an important role in their performance. Understanding this process requires knowledge about the water distribution during the uptake and the interaction between water and polymer. Most experimental techniques measure either the amount of water or water-polymer interactions but not water distributions. NMR imaging can be used to probe both water distributions and polymer-water interactions. The present study addresses water uptake and drying of a two-layered base coat/top coat system. The top coat is a highly crosslinked solventborne system. The base coat is a physically dried waterborne system consisting of acrylic, polyurethane and pigment particles. High resolution NMR imaging is used to measure water during the processes and a NMR relaxation analysis is used to probe water-polymer interactions. An asymmetry of uptake and drying behavior was observed. A theoretical model was proposed which explained this difference. It was found with NMR relaxometry that water is highly mobile in the polymer matrix and that polyurethane phase is plasticized by water.

Prof. Dr. Gordon Bierwagen

North Dakota State University, Fargo, ND, USA

Title lecture

Incorporation of Conductive Fillers into Mg-rich Primers

Authors

Jun Nie, Maocheng Yan, Gordon P. Bierwagen

Abstract

To substitute chromate based coatings, Mg-rich primers (MgRPs) have been developed by Bierwagen, Nanna, and Battochi etc, at North Dakota State University (NDSU, Fargo, North Dakota). In analogy to zinc-rich coatings technology, magnesium pigments were utilized as sacrificial corrosion inhibitors to provide cathodic protection to aluminum alloys. Conductive extenders like iron phosphide were incorporated into zinc-rich coatings to help to substitute part of the zinc pigment, reduce zinc pigment usage and improve coating physical properties. In this report, several conductive extenders have been incorprated into Mg-rich primers. Polarization tests, scanning vibrating electrode technique (SVET), open circuit potential (EOCP) and scanning electron microscopy (SEM) were used to characterize their primers. Scribed topcoated samples were placed in both cyclic and continuous salt spray chambers for long term exposure test. In cyclic salt spray (Prohesion®) chamber, it was found that conductive filler containing MgRPs clearly lowered the open circuit potential, enhanced the cathodic protection and prolonged the cathodic protection time. However, in continuous 5% salt spray chamber (B117), this cathodic protection enhancement effect was not so obvious, although panels containing conductive fillers performed better than their counterparts.

Gabriela Ciobanu*

Gheorghe Asachi" Technical University of Iasi, Faculty of Chemical Engineering and Environmental Protection, Iasi, Romania

*This lecture was presented by Dr Octavio Ciabanu

Title lecture

The effect of vitamins to hydroxyapatite growth on porous polyurethane substrate

Authors

G. Ciobanu, S. Ilisei, C. Luca, G. Carja, O. Ciobanu

Abstract

This work presents a study on an alternative coating method based on biomimetic techniques which are designed to form a crystalline hydroxyapatite (HA) layer very similar to the process corresponding to the formation of natural bone. The HA formation on the surface of porous polyurethane support is investigated. Two types of solutions such as supersaturated calcification solution (SCS) and modified SCS (M-SCS) were used to investigate bone-like apatite formation on polyurethane surface. The modified supersaturated calcification solution was prepared by added at original SCS appropriate quantities of vitamin A (A) and vitamin D2 (D). The hydroxyapatite deposits are investigated by means of scanning electron microscopy (SEM) and energy dispersive X-ray analysis (EDX). The data suggest that the method utilized in this work can be successfully applied to obtain deposition of uniform coatings of crystalline hydroxyapatite on porous polyurethane substrates.

Prof.Dr. Martien Cohen Stuart

Laboratory of Physical Chemistry and Colloid Science, Department of Agrotechnology and foodsciences, Wageningen University, Wageningen, The Netherlands

Title lecture

Chemistry and physics of associative thickeners

Authors

J. Sprakel, J. van der Gucht, P. Skrzezewska, F.A. de Wolf, M. Lemmers, M.A. Cohen Stuart

Abstract

Water-soluble polymers that can associate into reversible networks can be used as thickeners for water borne coatings. Such polymers have multiple, but at least two, associating blocks connected by hydrophilic, non-associating strands. In very dilute solutions, the associating blocks tend to form intramolecular associations, leading to small particles without connections. In more concentrated solutions, association is increasingly intermolecular, so that a network builds up. We discuss here associative thickeners with the simplest possible chain structure, namely so-called telechelics: triblock copolymers with a non-associating middle block and associating end blocks. We show how the structures of the networks formed by these polymers depend on the chemical architecture and the self-assembling properties of the end blocks. Not only do we discuss commonly used 'HEUR' thickeners which have simple alkyls as end blocks, but also two new types, namely one in which charged blocks drive association through electrostatic attraction, and another, bio-inspired variety which is based on self-assembly of peptide sequences. When such networks are sheared, associations break and reform at different rates, and a pronounced non-linear response on both mechanical and structural level is the result. We show how this response can be understood in terms of the underlying activated process by which intramolecular connections break, and how the chemical nature of the associating blocks affects this process. Finally, we show that a recent simulation method can accurately deal with all the observed features in a very satisfactory way.

Prof.Dr. Stuart Croll

North Dakota State University, Fargo, USA

Title lecture

The effect of pigments on the long term durability of artists´ oil paint

Authors

Stuart Croll, Marion F. Mecklenburg, Malia Zee

Abstract

It has long been appreciated by art conservation scientists that durability of artists' oil paintings depends crucially on the pigment used. Iron-based pigments and others produce films that remain very soft, and difficult to clean, whereas zinc oxide pigment produces very brittle films. White lead pigment yields paint that is very tough in comparison with the effect of other pigments. In addition, it has become apparent that the pigment in one layer may affect the properties of oil paint in neighbouring layers. Understanding how pigment chemistry affects the crosslinked polymer network in artists' paint is not only important in itself, but may have important applications, especially as higher performing polymers are sought using sustainable resources. Mechanical properties, such as tensile modulus, measured over 20 years, show how the films' toughness develops, and dynamic mechanical thermal analysis shows that there are substantial differences in the network formation over such periods. Combined with spectroscopic examination of the curing chemistry of the paints, these results give insights into how the various pigments can have such major effect on the long term properties of these, and perhaps other, paints.

Dirk Eierhoff

BASF Coatings GmbH, Muenster, Germany

Title lecture

On Cloud Nine - A Potential Evaluation Tool for Local Fluctuations of the Viewing Angle Dependent Brightness of Automotive Effect Coatings

Authors

Dirk Eierhoff, Georg Wigger

Abstract

Modern automotive effect coatings like so called "metallic shades" provide a viewing angle dependent brightness (and / or color) which underlines the three dimensional shape of a coated car body. These optical effects rely on a preferred orientation of pigment platelets like aluminum flakes parallel to the substrate surface. Depending on the coatings materials, the substrates as well as the coating process parameters the mean orientation of the pigments may vary locally yielding adjacent areas with slightly differing optical properties known as mottling or "clouds".

An evaluation of these fluctuations beyond visual inspection and rating has to rely on physical measurements of the local optical remission values of a coating and a thorough data treatment.

The presentation describes different measuring techniques and will focus on the challenge to establish examination methods based on a sound data treatment and interpretation which could be the basis for future evaluation tools in the industrial processing of effect coating materials in automotive paint shops.

Jacco Eversdijk*

TNO Science and Industry, Eindhoven, The Netherlands

Title lecture

Development of a biocide containing nano-clay composite for prolonged antifungal activity

*This lecture was presented by Dr. Bart Erich

Authors

J. Eversdijk, S.J.F. Erich, Miguel De Bolle, Kurt De Meyer, Dany Bylemans

Lecture will be presented by Bart Erich

TNO Science and Industry, Eindhoven, the Netherlanda

Abstract

The purpose of this project is adapting the release mechanism of biocides added to building materials to prolong the period of inhibition against biological growth. In a first step the minimum concentrations needed to inhibit biological growth were determined. In the next step, several biocides were intercalated into modified clay particles and the release of these biocides under different conditions was studied. Finally, the effect on the biological growth on gypsum samples, formulated with different biocide- organic modified particle, was studied. Chemical and biological analyses show that the biocide-clay composite material in gypsum shows a prolonged release of biocides. This unambiquously demonstrates its potential for practical applications.

Kostadinka A. Gesheva

Central Laboratory of Solar Energy and New Energy Sources - Bulgarian Academy of Sciences, Bulgaria

Title lecture

Transition metal oxide films: Technology and "smart windows" electrochromic device perfomance

Authors

K. A. Gesheva, T. M. Ivanova, M. Kozlov and S. Bojadjiev

Abstract

Transition metal oxides exhibit electrochromic effect, under a small voltage they change their optical transmittance from collored to bleach state. They are envisaged for application as smart windows in future architectural low-energy building, as well as as windows in car industry.

Smart window is a device controlling the energy of solar flux entering the building or car and make the interiors comfortable and at the same time energy utilization more effective. We have developed a whole optimized technology for deposition of thin films on conductive glass capable to change their transmittance if a small voltage (-1 - +2 volts) is applied across the film. Visually the film colours in a nice dark blue colour, and if the polarity of the voltage is changed the films bleaches up back to the initial transparency. Transition metal oxides due to their specific electronic structure are capable to exhibit this effect, called by Satyen Deb in 1968 electro chromic effect. He observed it in WO3 for the first time. Today the research is in the way to decrease the prise, to a few hundreds of dollars. The effect is well known, and the technology is necessary to be cost-effective. We offer the atmospheric pressure chemical vapour deposition as a very promising due to the fact that being an atmospheric pressure process it permits a flow-through technological manner, once the film growth-rate is enough high.

The paper deals with the optimization of a device, based on working electrode of WO3-MoO3 mixed films and counter electrode of MoO3CrO3 mixed film. The extensive research done on the film materials led to conclusion, that WO3-MoO3 mixed structure combines the excellent electro chromic performance of WO3 and the high-growth-rate of MoO3, when producing with the carbonyl APCVD process. Colour Efficiency approaching 200 cm²/C combined with optical modulation in the range of 65-70% (transmittance in bleached state) down to around 20-25% (transmittance in color state) are electrochromic performance characteristics acceptable for application.

As counter electrode, utilizing the same technology, Mo/Cr — based mixed oxide films were developed. These films do not exhibite electrochromic effect in cathodic regime, if applied as working electrodes. We employed these films as counter electrodes of the same device. Details about the electrochromic device made of transition metal oxide electrode materials, solid electrolyte containing optimized concentration of lithium ions, as well as discussion on the scan rate of potential applied for optimal device performance, will be the subject of the envisaged paper. Results from the voltammetry measurements of the electrochromic performance will be referred to film materials properties studied with high sensitivity characterization techniques like Field Emission Scanning Electron Microscopy, X-ray Photoelectron Spectroscopy, X-ray Diffraction, FTIR and Photospectroscopy measurement.

Jerneja Godnjavec

Center of Excellence for Polymer Materials and Technologies, Ljubljana, Slovenia

Title lecture

Polyhedral oligomeric silsesquioxanes as titanium dioxide surface modifiers for transparent acrylic UV blocking hybrid coating

Authors

J. Godnjavec, B. Znoj, N. Veronovski, P. Venturini

Abstract

Architectural coatings are usually recommended to enhance the durability of wood in exterior environment. Inorganic UV absorbers are often used to prolong the polymer stability in coatings formulation since they offer the most effective UV protection in the long term since they do not decompose and do not migrate in coating during weathering [1]. In the recent years, the preparation of polymer nanocomposite materials has been intensely considered due to their relatively remarkable various properties. Titanium dioxide (TiO2) enjoy manifold applications that include their usage as white pigment in the paint, plastic, and paper industries however it's nanoparticles in rutile crystal form have a special function as an inorganic UV shielding material. Currently, the requirement for optical materials with high refractive index and transparency in the fields of optical waveguides, antireflection coatings, adhesives for optical components and in our case especially for outdoor clear coating is increasing markedly. Significant properties of coatings with nano rutile particles are sufficient transparency and high absorption of UV light what can be achieved with nanoparticles of appropriate size and shape, narrow size distribution and excellent dispersability.

To achieve proper dispersion of nano-particles into the polymer matrix and to yield a better compatibility between the nano-particles and host polymeric materials, the use of different inorganic/organic post treatments for surface modification of nano-particles is recommended. The appropriate surface modification of nanoparticles also by formation of chemical and physical interactions with polymer matrix could guarantee a durable chemical junction between two incompatible phases.

In order to improve dispersability of nano-particles in polymeric materials, surface modification of TiO2 nano-particles in a polyacrylic clear coating were investigated. First, TiO2 nano-particle's surface was modified with inorganic oxide in order to reduce nanoparticles agglomeration, to enhance photochemical stability and finally to improve TiO2 dispersability. Second, Polyhedral Oligomeric Silsesquioxane (POSS) molecules were used to additionally enhance the dispersion homogeneity of nanosized TiO2. in rutile crystale form in acrylic water based transparent coating. POSS nanostructures provide a unique approach to the development of polymeric nanoengineered materials. POSS molecules are cage like organic-inorganic structures described by the general chemical structure RSiO1,5. Nanoparticle shape, size and microstructural analysis was done by analytical electron microscopy (AEM) while particle size distribution was performed by DLS technique. The grafting of POSS-molecules on the nano-particles surface was characterized with TGA and FTIR techniques. The stability of TiO2 rutile nanoparticles in an acrylic clear coating was evaluated by zeta potential measurement. Improved performance of grafted nano TiO2 with inorganic and POSS surface treatment in nanocomposite coatings was demonstrated trough UV-VIS spectroscopy and accelerated weathering.

References

- A. Classen, T. Rentschler, Mater. Testing Prod. Technol. News 37 (80) (2007) 9.

Gustavo L. Guerriero

Structural Integrity, Faculty of Aerospace Engineering, Delft University of Technology, Delft, The Netherlands

Title lecture

Mechanical properties of Liquid Crystalline Thermosetting Coatings

Authors

Gustavo L. Guerriero, Santiago J. Garcia, Erik Schlangen, René Alderliesten, Rinze Benedictus

Abstract

Liquid crystalline polymers (LCPs) are gaining interest in recent years due to their unique combination of mechanical properties, chemical resistance, barrier properties and dimensional stability. Previous studies have given a first insight in the potential use of novel liquid crystalline thermosets (LCTs) for coating applications. Despite the first results showing the high adhesion and easier processability of these new systems, more fundamental studies are required to understand and optimize mechanical and adhesive properties, amongst others. In the present work, phenylethynyl terminated liquid crystalline oligomers based on 4--hydroxy-benzoic acid (HBA) and 6-hydroxy-2-naphthoic acid (HNA), with molecular weights from 1 to 13 Kg/mol, were applied, using a melt-press, on aluminum alloy AA5083. This investigation focused on understanding the influence of the molecular structure and processing on the surface mechanical behavior and scratch resistance of LCTs. The effects of diverse substrate pretreatments on adhesion were also investigated. A nanoindenter with constant stiffness measurement (CSM) and a microscratch system were used in combination with confocal and electron microscopy. Results correlated with previous thermomechanical studies of free-standing films; furthermore, they showed an important influence of the molecular weight and macroscopic orientation not only on the mechanical properties, but also on the topography of the coatings.

Yong He

School of Chemistry and Chemical Engineering, South China University of Technology, Guangzhou, China

Title lecture

A Recycling Model of Excess 2, 4-and 2, 6-Toluene Diisocyanate in the Preparing of Polyurethane Prepolymer

Authors

Yong He, Xinya Zhang, Huanqin Chen

Abstract

The step-wise polyaddition between toluene diisocyanate (TDI) 80 and hydroxyl terminated trimethylolopropane (TMP) at various temperatures and initial NCO/OH ratio was followed by Backtitration and High Performance Liquid Chromatography (HPLC). The kinetics of this system was well described by a second order equation when the polyols were added dropwise compared to the general one-pot method. This procedure was optimal by comparing the deviations between experimental date and theoretical calculation data. Three standard commercial TDI (TDI100, TDI80 and TDI65) were used to investigate the effect of temperature, NCO: OH ratio and isomers ratio R on the end point of the reaction comprising -NCO and unreacted isomeric TDI and isomer reaction constant β. A recycling model of unreacted isomeric TDI and solution was established to ensure a stable process and resulting products with good repeatability. This model has been applied in the chemical plant to prepare polyurethane prepolymer with precisely defined chemical compositions in a consecutive process.

Anthony E. Hughes

Commonwealth Scientific and Industrial Research Organisation, Division of Materials Science and Engineering, Clayton, Australia

Title lecture

Using X-ray Tomography, PALS and Raman Spectroscopy to Characterisation Inhibitors in Epoxy Coatings

Authors

A.E. Hughes, S. Mayo, Y. S. Yang, T. Markley, S. V. Smith, Selvakumar Sellaiyan, S.G. Hardin and T.H. Muster

Abstract

Inhibitors (Zn3(PO4)2 and SrCrO4) and Fillers (Rutile TiO2) were added to epoxy matrices to create model primer systems for further study. The SrCrO4 system was characterized using SEM, TEM PALS and Raman spectroscopy and found to have an even distribution of inhibitor in the polymer matrix. X-ray Tomography was performed on both systems. A new technique called data constrained modeling was combined with the tomographic technique to produce a 3D distribution of the inorganic phases within the polymer matrix.

Alexander Irzh

Department of Chemistry and Kanbar Laboratory for Nanomaterials at the Bar-Ilan University Center for Advanced Materials and Nanotechnology, Bar-Ilan University, Ramat-Gan, Israel

Title lecture

Super-fast deposition of transparent super-hydrophobic layers on various surfaces using microwave plasma

Authors

Alexander Irzh, Guy Applerot and Aharon Gedanken

Abstract

We report on very fast and simple production of transparent superhydrophobic surfaces by using microwave (MW) plasma. It was found that by reacting various organic liquids in MW argon plasma, these materials are polymerized and the substrates including the plasma chamber walls are coated by hydrophobic polymer. In most cases, these polymers are deposited as rough layer of ~10 nm nanoparticles. This roughness, together with chemical hydrophobisity, is responsible for the superhydrophobic nature of the surface. The coated surfaces included: glass slides, polymer slides like polycarbonate, silicon wafers, metallic plates (stainless still and aluminum) and even paper. The typical reaction time of the coating procedure was 1-10 sec.

Alexandros Kakaroglou

Vrije Universiteit Brussel (VUB), Research Group of Electrochemical and Surface Engineering (META), Brussel, Belgium

Title lecture

Characterization of plasma polymerized poly (allyl methacrylate) coatings

Authors

A. Kakaroglou, G. Scheltjens, F. Dabeux, I. De Graeve, G. van Assche, B. Van Mele, R. Willem, F. Reniers, H. Terryn

Abstract

Allyl Methacrylate (AMA) has been deposited on aluminium substrate using atmospheric plasma. Fourier-transform Infrared Spectroscopy (FT-IR), X-Ray Photoelectron Spectroscopy (XPS) and Visual Spectroscopic Ellipsometry (VISSE) were used to determine the chemical composition and the thickness of the coatings. Differential Scanning Calorimetry (DSC) has been used for the determination of the glass transition temperature. Cut-off test have been performed to evaluate the adhesion to the substrate. An atmospheric plasma Dielectric Barrier Discharge setup has been used for the depositions. The monomer was carried to the plasma chamber by means of a argon flux passing into a bubbler. The influence of the discharge power on the chemistry has been investigated. FTIR spectroscopy shows the influence of the discharge power on the COOR and C=C of the coatings. XPS confirms these results. The influence of the monomer concentration on the chemistry and the thermomechanical properties of the produced coatings have been studied.

Prof.Dr. Andreas Kandelbauer

School of Applied Chemistry, Reutlingen University, Reutlingen, Germany / Department of Wood Science and Technology, University of Natural Resources and Life Sciences, Vienna, Austria

Title lecture

Photocrosslinkable vegetable oil modified resin for fiber reinforced composite and wood surface coating application

Authors

Arunjunai Raj Mahendran, Günter Wuzella, Nicolai Aust, Andreas Kandelbauer

Abstract

A novel acrylated epoxidized linseed oil (AELO) was synthesized from epoxidized linseed oil through ring opening of the oxiane group using acrylic acid as the ring opening agent. The occurance of the acrylate group and the ring opening of the epoxidized linseed oil using acrylic acid were characterized using FT-IR, 1HNMR and oxirane index values. The synthesized AELO was cured under UV radiation using three different photoinitiators. The time of exposure was varied and the cure kinetics was evaluated. The AELO cured on wood and natural fiber reinforced composites surfaces were tested and the technological surface properties were correlated to the degree of cure of partially and fully cured AELO coating.

Christine Y.W. Lin

School of Materials Science and Engineering, University of New South Wales, Sydney, NSW, Australia

Title lecture

Mn-Doped Titania Thin Films Prepared by Spin Coating

Authors

C.Y.W. Lin, A. Nakaruk, C.C. Sorrell

Abstract

TiO2 thin films doped with =7 mol% Mn (metal basis) were deposited on F-doped SnO2-coated glass substrates by spin coating. The structural, morphological, and optical properties of the films were investigated by glacing angle X-ray diffraction (GAXRD), laser Raman microspectroscopy, field emission scanning electron microscopy (FESEM), and ultraviolet-visible spectroscopy (UV-VIS). Mn doping of TiO2 (anatase) extended the optical absorption edge to significantly longer wavelengths (lower photon energies) and hence lower band gaps.

Mohsen Mohseni

Department of Polymer Engineering and Color Technology, Amirkabir University of Technology, Iran

Title lecture

Structural and Morphological Studies of Scratch Resistant Sol-Gel Based UV Cured Nano Composite Films on Polycabonate

Authors

H.Yahyaei, M.Mohseni, S.Bastani

Abstract

Polycarbonate (PC) is one of the most usable thermoplastic engineering plastics because of its high toughness and transparency. However, low crystallinity of PC makes it low scratch resistant, resulting in reduced clarity during its service life. Use of highly cross-linked thermosetting polymeric coatings such as UV curable resins, is a good alternative to overcome this problem. Furthermore, modification of these coatings by inorganic nano particles will enhance the scratch resistance. A versatile chemistry based on sol-gel processing has recently shown that organic-inorganic hybrid coatings can be obtained in which the properties of organic phase can be combined with those of inorganics to produce high scratch resistant nanocomposite films on PC. In this study, nano silica networks prepared using hydrolysis and condensation of silane coupling agents were embedded into UV curable urethane acrylate oligomers. Tetraethyl orthosilicate (TEOS), as network former, and tri-methacryloxypropyl trimethoxy silane (MEMO), as network modifier , were utilized. The effect of molar ratio of TEOS/MEMO and inorganic/organic contents on morphology and mechanical properties of hybrid coatings were investigated. Increasing TEOS/MEMO and inorganic/organic ratios were found effective to enhance mechanical properties and scratch behaviour. Nanoindentation and nano scratch testings were conducted to correlate the interfacial interaction of phases to the mechanical performance of nano composite films. With increasing TEOS/MEMO molar ratio, as well as inorganic /organic weight ratio, penetration depth and width of scratch area decreased, indicating that scratch resistance increased. This behaviour corresponds to the increased elastic modulus due to the ability of coatings to plastically deform. This arised from an increase in glass transition temperature (Tg) as revealed by Dynamic Mechanical-Thermal Analysis (DMTA). Morphological analysis of films using Small Angle X-ray Scattering (SAXS) revealed that with higher loadings of TEOS/MEMO, mass fractal dimension increased, showing that a more compacted structure had formed. The greater the compactness and the smaller the particles size, the lower is segmental motion of polymer chains and therefore the higher are Tg and elastic modulus. FTIR analysis showed that TEOS with 4 alkoxide functional groups could form a more complete structure. MEMO with a longer organic chain having maximum 3 functionality creates an open structure. This more open structure gives rise to higher free volume and decreased Tg.. Although SAXS data showed that a greater phase separation occurred upon increasing TEOS/MEMO ratio , this phase separation was not detrimental to influence transparency of hybrid nano coatings.

Thibault Muselle

Vrije Universiteit Brussel, Group of Electrochemical and Surface Engineering, Group of Physical Chemistry and Polymer Science, Brussels, Belgium

Title lecture

Multiple action self-healing coatings for the corrosion protection of metals

Authors

T. Muselle, G. Scheltjens, J. Brancart, Y. Gonzalez-Garcia, J.M.C. Mol, I. De Graeve, G. Van Assche, B. Van Mele, H. Terryn

Abstract

In this work, multiple action self-healing properties of a polymer coating doped with a cerium based corrosion inhibitor were studied. Measurements showed a good closure of scratches after a heat treatment. It was proven that this closure was accompanied by a good recovery of the barrier properties. In case of a cerium doped coating, the application of a scratch caused the precipitation of CeO2, responsible for the inhibition of the corrosion activity. This inhibition was analyzed with different electrochemical techniques, all resulting in the conclusion that a good corrosion inhibition was attained. When combining both self-healing mechanisms, satisfying multiple action self-healing was attained, offering corrosion protection after the creation of a scratch, followed by a recovery of the barrier properties after a heat treatment.

Mark E. Nichols

Ford Motor Company, Dearborn, MI, USA

Title lecture

Accelerated Weathering Testing: A New Approach to Anticipating Florida Exposure Results

Authors

M.E Nichols, J. Boisseau, L. Pattison, J. Quill, T. Misovski* C.A. Peters, J. Zhang, K. Henderson, D. Smith, J.E. Seebergh, and D.H. Berry

Abstract

The lack of correlation between accelerated artificial weathering and natural outdoor weathering is a major obstacle in developing and commercializing new coating systems. False positives lead to significant and costly failures in the field. False negatives produce lost business opportunities. To address this fundamental gap, a new accelerated weathering protocol has been developed that significantly improves the correlation between failure modes observed after Florida exposure and failure modes observed after accelerated artificial weathering exposure. Florida was chosen as the comparator location due to its historical significance and the large database of coating performance that exists for that location. Multiple paint systems (waterborne, solventborne, basecoat/clearcoat, monocoat, primerless) were exposed in south Florida, USA, and in both rotating drum and flat array accelerated weathering devices. Degradation was followed by measuring gloss loss, color change, and physical signs of deterioration, such as cracking, blistering, or loss of adhesion. In addition, chemical composition changes were quantified through the use of FTIR spectroscopy by measuring growth in the -OH,-NH portion of the spectrum. The rate of UV light absorber loss was determined via micro UV spectroscopy on complete paint systems.

Dr. Harald Oehler

Deutsches Kunststoff-Institut, Darmstadt, Germany

Title lecture

Investigation of delamination mechanisms in coatings by scanning acoustic microscopy

Authors

H. Oehler, M. Bargmann, D. Lellinger, I. Alig

Abstract

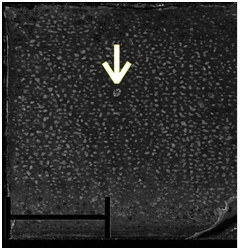

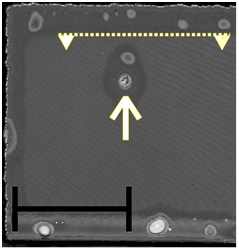

Scanning acoustic microscopy (SAM) has been found before to be well suited to study physically and chemically induced changes in polymer coatings exposed to corrosive environments [1, 2]. In this study SAM was used to investigate disbonding, delamination and blister formation in polymer coatings for different layer structures and initial defect depths after different time intervals of exposure to a corrosive environment [3, 4]. In this work the time evolution of disbonding and blister initiation and their growth was investigated by analysing the SAM images after exposure to an electrolyte solution (Harrison solution). From investigations of a model system of coatings on steel substrates, it was possible to differentiate between water and/or ion transport (i) through the coating and (ii) along the coating-steel interface. For samples without clear coat randomly distributed blisters appeared at the coating-steel interface after exposure to the electrolyte solution (fig. 1 left), irrespective of the location of initial defects. The random distribution of growing blisters is related to diffusion of water and/or ions through the coating and "defect nucleation" at weak points of the substrate or within the polymer. For samples with clear coat a propagating migration front along the coating-steel interface of 3-4 µm height - starting from initial defects - was detected (fig. 1 right). The linear propagation of this front cannot be explained by Fickian diffusion. Therefore, it is discussed in terms of an accelerated diffusion or crack growth kinetics. For nucleation of blisters it was found, that the migration front must have been passed before. The migration front is related to a loss of adhesion and following corrosive processes [5].

Figure 1: Statistically distributed blisters on a coating system without clear coat (left); migration fronts and subsequent appearing blisters on a coating system with clear coat. Black scale is of 10 mm length.

References

- B. Reddy, J. M. Sykes, Progress in Organic Coatings 52 (2005) 280-287.

- B. Reddy, M. J. Doherty, J. M. Sykes Electrochimica Acta 49 (2004) 2965-2972.

- I. Alig.; S. Tadjbach.; P. Krüger, H. Oehler, D. Lellinger.: Progress in Organic Coatings Vol. 64 (2009) 112.

- H. Oehler, M. Bargmann, D. Lellinger, I. Alig.: Farbe&Lack Vol. 117 1. (2011) (accepted).

- P.A. Sorensen, K. Dam-Johansen, C.E. Weinell, S. Kiil.: Progress in Organic Coatings Vol. 68 (2010). 283.

Biography

- Diploma, Physics, Technische Universität Darmstadt, Germany 1996-2001

- scientific assistant, German Institute of Polymers, 2002-now

Fields of activity:

- Film formation of coatings

- UV-curing of adhesives

- Ageing of coatings and adhesives

- Development and application of measurement methods

Siriwan Phattanarudee

Department of Imaging Science and Printing Technology, Faculty of Science, Chulalongkorn University, Bangkok, Thailand

Title lecture

Preparation of Biodegradable Nanocomposite Emulsions

Authors

S. Phattanarudee, K. Sermsantiwanit

Abstract

Biodegradable nanocomposite latexes were prepared by emulsification-diffusion method, which consisted of emulsifying a solution of biodegradable polymer and clay in an aqueous phase containing surfactants. Two kinds of silicate, sodium motmorillonite and organo-modified montmorillonite, were compared. Influences of silicate concentration (1-6%wt) on average particle size and particle morphology, and thermal properties of the resultant nanocomposite films were investigated. The average particle size was found in a range of 20-30 micron, depending on the silicate content. The emulsion prepared with sodium motmorillonite yielded the average particle size in close proximity to the one obtained with organo-modified montmorillonite. SEM micrographs revealed that the resultant microspheres attained a smooth spherical shape with different sizes. Thermal properties of the nanocomposite films were improved compared to that of the pristine film. The highest thermal stability was achieved with the highest amount of added clay (at 6%wt) of the film containing sodium motmorillonite. Such nanocompoiste latexes maintained good stability for 6 months. The obatainable nanocomposite emulsions could be served as a novel biodegradable coating with enhanced thermal properties.

Claudia Philipp

Fraunhofer Institute for Wood Research, Wilhelm-Klauditz-Institut (WKI), Braunschweig, Germany

Title lecture

Waterborne polyurethane wood coatings based on rapeseed fatty acid methyl esters

Authors

C. Philipp, S. Eschig.

Abstract

Trends in wood coatings are driven to waterborne systems and to renewable resources. Vegetable oils are well known for wood coatings, e.g. alkyds or polyurethane dispersions. In this context fatty acid methyl ester (biodiesel) turns out to be an alternative to technical fatty acids and vegetable oils. High contents on hydrophobic oil based monomers require a sufficient understanding of the dispersion stability. This study shows the influence of hydrophobic monomers, ionic centers, degree of neutralization, and stirring procedure to the particle size distribution and dispersion stability. Furthermore, the impact of these parameters to the resulting coating film properties was investigated.

Christoph Regula

Fraunhofer Institute for Manufacturing Technology and Applied Materials Research, Bremen, Germany

Title lecture

Corrosion protection of metal surfaces by atmospheric pressure plasma jet treatment

Authors

C. Regula, T. Lukasczyk, J. Ihde, R. Wilken

Abstract

Metals can be found in many industrial applications, e.g., as conductive paths for electronic devices (e.g., copper) or as the load-bearing parts of cars and airplanes (e.g., aluminium alloys). To prevent their degradation under atmospheric conditions, usually thick polymer coatings or lacquers are applied for corrosion protection. The application and curing of such coatings require a high amount of time, energy and space. Another disadvantage is the low heat conductance of the resulting coatings. We studied the use of an atmospheric pressure plasma (APP)-jet system (Plasmatreat) for the pre-treatment of surfaces and deposition of thin protective coatings in the sub-μm range on metals as an alternative, environment-friendly process

Nadine Tenn

Laboratoire Polymères Biopolymères Surfaces, UMR CNRS 6270 & FR 3038, Université de Rouen, Mont Saint Aignan Cedex, France

Title lecture

Water barrier properties of plasma treated EVOH and PLA films

Authors

Nadine Tenn, Nadège Follain, Kateryna Fatyeyeva, Jean-Marc Valleton, Fabienne Poncin-Epaillard, Stéphane Marais>

Abstract

Poly(ethylene-co-vinyl alcohol) and polylactic acid films have been modified by cold plasma treatment using CF4, trimethyl silane (TMS) and mixtures CF4/H2 and CF4/C2H2. Chemical changes of the film surface were characterized by X-ray photoelectron spectroscopy (XPS). The results revealed the presence of fluorine containing functional groups in the case of fluorine plasma treatment and the presence of SiOxCy compounds for TMS treatment. The morphology of the plasma treated films were examined by atomic force microscopy (AFM). Slight changes of thermal properties of the modified films were observed by the means of the temperature modulated differential scanning calorimetry (TMDSC). The film surface properties were evaluated by the water permeability and the water vapour sorption measurements.

Russel J. Varley

CSIRO Materials Science and Engineeing, Clayton South, Australia

Title lecture

Investigation of Factors Impacting the In-Service Degradation of Aerospace Coatings

Authors

R. J. Varley, E.K. Simmonds, J.E Seebergh: and D.H. Berry

Abstract

The exterior decorative coating is one of the most visible elements of a commercial airplane, projecting a corporate image and differentiating among airline operators. Depending on the service environment, aerospace topcoats may experience premature loss of gloss, color shift, adhesion failures, and cracking, negatively impacting both appearance and performance. The objective of the current work was to investigate variations in irradiance, temperature, particulate matter, acid environment, and moisture on the physical and chemical properties of multiple colors of polyurethane-based monocoats, with and without clearcoat. Color, gloss, surface roughness, hardness, and chemical composition were measured as a function of radiant exposure to 15,000 kJ/m2. Increasing the temperature was found to accelerate color shift (ΔE) and loss of gloss, while increasing the irradiance did not have significant effect on color and gloss for a given radiant exposure, suggesting that increasing irradiance is an approach for accelerating weathering testing without altering the degradation mechanism. Systematic decreases in amide concentration, as measured by FTIR spectroscopy, correlated directly with increases in ΔE, with all data falling on a universal curve. The knowledge gained from this work provides a better understanding of coating degradation and aids in development of new test methods and more durable coatings.

Polina Volovitch

Ecole nationale supérieure de chimie de Paris (ENSCP): Paris, France

Title lecture

New approach for measuring reactivity and degradation of complex surfaces: a review of recent results

Authors

P.Volovitch, Co-authors L. Jiang, T.-N. Vu and K. Ogle

Abstract

For complex materials selective dissolution, precipitation and continuous change of pH result in the impossibility to reach a steady state. The steady state is rarely achieved during surface treatment (alkaline cleaning, pickling, conversion coating bath etc.). Recently developed in our group technique, atomic emission spectroelectrochemistry (AESEC) couples a small volume electrochemical flow cell to an inductively coupled plasma atomic emission spectrometer, positioned downstream. In this way the current transients occurring in the electrochemical cell may be correlated with concentration transients in the electrolyte such that the total electrochemical current may be resolved into elementary dissolution reactions. The steady state is not necessary to interpret the results. From a quantitative analysis of this information, the surface excess of different elements may also be determined and the formation of oxides can be estimated. In the present work we will review our recent results dealing with AESEC application to understand different stages of surface pre-treatment and corrosion. Examples of mechanistic interpretations for the pickling reactivity of mild steel in presence of organic inhibitor, the oxide characterization and dealloying phenomena of Zn and Al based metallic coatings on steel [3,4], the selective dissolution during anodizing and the degradation of phosphate conversion coating will be discussed.

Andriy Voronov

Coatings and Polymeric Materials, North Dakota State University, Fargo, ND, USA

Title lecture

Interfacial behavior of self-assembled micellar nanostructures from stimuli-invertible macromolecules

Authors

Andriy Voronov

Abstract

Interest in nanomaterials derived from amphiphilic self-assembling systems, including polymers, has dramatically increased over the past few years. The main challenge for scientists is to find new systems and materials that have enhanced properties and the potential to replace existing classic systems. These new materials have to face new and increasingly sophisticated demands of industry, where nanomaterials are finding wider niches.

Responsive polymers adapt to surrounding environments, can regulate transport of ions and molecules, change wettability and adhesion of different species on external stimuli etc. Amphiphilic molecules, which are molecules with polar and non-polar moieties, arrange themselves at interfaces and tend to build aggregates in solution.

Recently, the focus of research in the field of polymeric materials has moved toward the design of polymers with smart responsive behavior. For this reason, our research group has recently carried out a broad study on synthesis, characterization and properties of amphiphilic invertible polymers (AIPs) composed of the hydrophilic and hydrophobic constituents alternately distributed along the main backbone. The preparation of self-assembled functional micellar nanostructures from AIPs is a one novel and promising approach. Made from hydrophobic and hydrophilic constituents that are alternately distributed along the polymer backbone, AIPs form invertible polymeric micelles or self-arranged aggregates of micelles in response to tuning of the polymer concentration and environmental polarity. The resulting complex nanostructures have a controlled size and morphology and are functional in both polar and non-polar environments, giving them potentially broad use in many chemical and biochemical applications. In particular, they can be used as nanoreactors for the synthesis of nanoparticles that have a protective shell made from both hydrophilic and hydrophobic polymeric fragments, and, thus, will be highly stable in both polar and non-polar environments. The ability to encapsulate insoluble substances makes their use as polymeric nanocontainers especially promising for the pharmaceutical industry (controlled release, targeted devices), agriculture (micronutrient delivery, development of fertilizers), and cosmetics (encapsulation of functional ingredients and their delivery).

Hirotsugu Yasuda*

Department of Chemical Engineering, University of Missouri, Columbia, MO, USA

Title lecture

Green System Approach Interface Engineering for Coating of Metals; DC Plasma Polymerization and Magneto-Plasma Polymerization

*This lecture was presented by Dr Fethi Olcaytu (Univeristy of Freiburg, Germany)

Authors

Hirotsugu Yasuda, Loic Ledernez, Fethi Olcaytug, and Gregory Dame

Lecture will be presented by Dr Fethi Olcaytug

University of Freiburg, Freiburg, Germany

Abstract

Interface of substrate and coating as well as of the top-surface of coating and the surrounding medium, in which coated material is used, plays the key role in determining the ultimate value of the coating applied. However, a coating to fulfill the different requirements on both sides of a coating is virtually impossible, and interface engineering on both sides of coating is necessary. Conventional wet chemistry approach rely on Galvanic protection such as chromate conversion coating and zinc phosphate coating which require additional environment remediation processes in coating application and leave the products as potential environmental hazard when the products have to be recycled. In this respect, tailored nanofilms (10 - 30 nm) application by plasma polymerization provides unique advantages that the interface engineering can be achieved by green processes that do not cause environmental hazard and also the products can be recycled without causing environmental hazard. These features are particularly valuable in coating of metals used in bio-medical devices that require bio-compatible inter face engineering.

The interface engineering on substrate/coating and coating/surrounding medium by means of plasma polymerization coating of nano-films have shown remarkable improvements of coating in various applications such as corrosion protection, sustainable surface and transport characteristics of coating, and imparting bio-compatibility to artificial materials [1-5]. It should be pointed out, however, that the plasma polymerization coating used in the interface engineering mentioned above are not conventional RF or Microwave plasma polymerization. DC plasma polymerization is exclusively used for coating on metallic (electrically conducting) substrates, and magneto-plasma polymerization by AF (10 - 50 kHz) is used for dielectric substrates, usually polymer coatings. The latter method yield significantly better nano-film coating than conventional RF plasma polymerization coating with respect to 1) adhesion to substrate, 2) sustainable surface properties, and 3) tunable transport characteristics. These aspects have been confirmed by recent studies on the initial step of creating electrically conducting luminous gas phase. The magneto-plasma polymerization is nearly totally different from RF plasma polymerization.

The conventional approach in investigation of gas phase breakdown assumes that low temperature plasma is created by ionization of gas, and accordingly only breakdown voltage, Vb, has been investigated as a function of pressure and the separation distance, d, of cathode and anode in DC discharge. It has been recognized that the glow develops with organic molecules are significantly different from that of atomic gases, such as Ar [1, 2]; the dissociation of organic molecules occurs first and plasma polymerization in DC discharge is controlled by the current density near the cathode, and the DC voltage has no influence on plasma polymerization [3, 4]. In recent study, breakdown process was investigated as function of breakdown voltage, Vb, and current, Ib, and derivative parameters; conductivity of broken down gas phase, and the energy transfer parameter, which is given by energy per mass of the feed gas. It was found that the variation of Vb due to types of gas is marginal; variance is much smaller than that observed with changes of operational parameters due to the size of reactor for Ar glow discharge. On the other hand, change of Ib due to types of gas is remarkably great. Since variance in Vb is small, all derivative parameters follow the same pattern observed with Ib. Without magnetic field, the increase of discharge current occurs only above the transition point pressur

The conductivity of broken down gas phase is dependent on the dissociation of organic molecule and the electro negativity of atoms in a molecule. The gas phase breakdown can be viewed as creation of excited species with high electron transfer capability rather than ionization of gas. The electron transfer capability of medium could be explained by analogy to the energy transfer of tsunami by water, which is not being transferred.

The influences of magnetic field on gas phase breakdown clearly showed remarkable influence of magnetic field on the breakdown process. Very high electron transfer occurs by low applied voltage in very low pressure where no energy transfer takes place without magnetic field. With magnetic field, the formation of reactive species and their deposition in form of nano-film occur at low-pressure, which is below the minimum point pressure without magnetic field. How these unique features provide amorphous CHx nano-film, with remarkable bio-compatibility, from CH4 will be explained with polymer formation/deposition mechanism, and its implications to the interface engineering of polymer coatings.

References

- H. Yasuda and Q. Yu, Plasma Chemistry & plasma process, 24, 325, (2004).

- Q.S. Yu, C. Huang, and H.K. Yasuda, J. Polym. Sci., A: Polym. Chem., 42, 1042, (2004).

- M. Miyama and H. Yasuda, J. Appl. Polym. Sci., 70, 237 - 245, (1998).

- Q.S. Yu and H.K. Yasuda, Plasmas and Polymers, 7, 41, (2002).