Speakers COSI 2012

- Mina Abdolah Zadeh, Delft University of Technology, Delft, Nederland, Corrosion Trigerred Self-healing Sol-Gel Coatings

- Dr. Ingo Alig, Deutsches Kunststoff-Institut, Darmstadt, Germany, Film formation, curing and properties of carbon nanotube-modified coatings for aircraft applications and electrical industry

- Worawan Bhanthumnavin, Chulalongkorn University, Bangkok, Thailand, Aromatic phosphorodiamidate curing agent for epoxy resin coating with flame-retarding properties

- Zbigniew Boncza-Tomaszewski, Industrial Chemistry Research Institute, Department of Polyesters, Epoxides and Polyurethanes, Warszawa, Poland, New toxicologically-safe cross-linkers for powder coatings

- Dr. Elisa Campazzi, EADS Innovation Works, Metallic Technologies and Surface Engineering, Suresnes, France, Alternatives to Chromate Systems for Corrosion Protection in Aerospace: Study of "Green"-Inhibitor Loaded Spheres in Model Sol-Gel Coatings

- Gary Craun*, Global Research, AkzoNobel Packaging Coatings, Strongsville, Ohio, USA, Polyether Polyols and Water Borne Acrylic Grafted Polyether Polyols Synthesized with Epoxidized Soy Bean Oil

- Dr. Marc Entenmann, Fraunh. Inst. for Manufacturing Engineering and Automation, Germany, Monitoring of degradation process in automotive - multilayer coatings using photooxidation index

- Dr. Céline Falentin, Center for Education and Research on Macromolecules (CERM), University of Liège, Liège, Belgium, A water-based antibacterial nanohybrid solution for coatings on steel

- Vanesa García-Pacios, Adhesion and Adhesives Laboratory, University of Alicante, Alicante, Spain, Incidence of the polyol nature used in the synthesis of waterborne polyurethane dispersions intended for use as coatings

- Dogan Gunbas, Laboratory of Polymer Chemistry, Eindhoven University of Technology, Eindhoven, The Netherlands, PDMS-modified poly(styrene-alt-maleic anhydride) as waterborne coating based on surfactant-free latex

- Assist.Prof. Mogens Hinge, Dept. of Eng. Aarhus University, Aarhus, Denmark, Organic coatings based on aryldiazonium salts

- Dr. Maude Jimenez, UMET, équipe ISP-PERF, CNRS UMR 8207, Université Lille Nord de France, ENSCL, Villeneuve d´Ascq cedex, France, Protective coatings for reaction and resistance to fire of materials

- Prof.Dr. Joseph L. Keddie, Department of Physics, University of Surrey, Guildford, Surrey, UK, Bespoke Patterned Coatings via Infrared Radiation-Assisted Evaporative Lithography

- Assist.Dr. Søren Kiil, Department of Chemical and Biochemical Engineering, Technical University of Denmark, Lyngby, Denmark, Quantitative analysis of photoinitiated coating degradation at constant artificial exposure conditions

- Prof.Dr. Cor Koning, Laboratory of Polymer Chemistry, Eindhoven University of Technology, Eindhoven, the Netherlands / DSM Coating Resins, Zwolle, the Netherlands, Novel coating resins based on poly(ester)carbonates made by catalytic chain growth polymerization of epoxides, anhydrides and CO2

- Sviatlana Lamaka, Instituto Superior Tecnico, Lisbon, Portugal, Fault-Tolerant Hybrid Epoxy Silane Coatings for Corrosion Protection of Mg Alloys

- Prof. Joëlle Levalois-Grützmacher, Department of Chemistry, Swiss Federal Institute of Technology, ETH Hönggerberg, Zürich, Switserland, Flame-retardant finishing by a low pressure plasma process on cotton textiles in combination with dyeing

- Dr. Bas Lohmeijer, BASF SE, Ludwigshafen, Germany, Prefered partitioning: the influence of coalescents on the build-up of mechanical properties in acrylic core-shell particle

- Dr. Kimihiro Matsukawa*, Electronic Material Devision, Osaka Municipal Technical Research Institute, Osaka, Japan, Photo-cured Organic-inorganic Hybrid Thin Films with Controlled Refractive Index

- Mohor Mihelčič, National Institute of Chemistry, Ljubljana, Slovenia, Electrochromic TiO2 pigment coating and plastic film-based NiO/TiO2 device with transmissive light modulation

- Karuppiah Murugan , International Advanced Research Center for Powder Metallurgy and New Materials, Hyderabad, India, Synthesis, characterization and demonstration of self-cleaning TiO2 coatings on glass and glazed ceramic tiles

- Dr. Yutao T. Pei, Materials innovation institute M2i, Department of Applied Physics, University of Groningen, Groningen, The Netherlands, Flexible protective diamond-like carbon films on rubbers

- Dr. Alexander Routh*, BP Institute for Multiphase Flow & Department of Chemical Engineering and Biotechnology, University of Cambridge, Madingley Rise, Cambridge, UK, Evaporation mediated self assembly of nanoparticles: Watching paint dry

- Dr. Eriko Sato, Department of Applied Chemistry and Bioengineering, Graduate School of Engineering, Osaka City University, Osaka, Japan, Reversible Volume Changes of Polymer Thin Films and Their Application to Wettability Control

- Prof.Dr.Ing. Wilhelm Schabel*, Karlsruher Institut für Technologie (KIT), Institut für Thermische Verfahrenstechnik, Bereich: Thin Film Technology (TFT), Technologie dünner Schichten, Germany, Drying of thin films – structrue and morphology formation with processing related aspects

- Artur Siwek, ABB Corporate Research, Krakow, Poland, Adhesion of epoxy resin to a low friction coatings and its correlation with tribological properties

- Dr. Mark Soucek*, The University of Akron, College of Polymer Science and Polymer Engineering, USA, Self-Stratifying Coatings

- Dr. Thomas Stimpfling, Laboratoire des Matériaux Inorganiques, UMR CNRS 6002, Université Blaise Pascal, AUBIERE, France, EDTA interleaved LDH as efficient epoxy coating pigment for Aluminium corrosion protection

- Assoc. Prof. Shujuan Tan, College of Material Science & Technology, Nanjing University of Aeronautics and Astronautics, Nanjing, PR China, Preparation and properties studies of paraffin/high density polyethylene composites and phase-change coatings

- Madeleine Tchoquessi Diodjo, Université du Sud Toulon Var, France, Influence of silane-based treatment on adherence and wet durability of fusion bonded epoxy/steel joints

- Jesús Vega, TU Delft, Delft, The Netherlands, Ionomers as self-healing coatings for metal protection

- Prof. Lars Wågberg*, KTH Zweden, Tailoring of adhesion using non-covalent physical modifications with the aid of the Layer-by-Layer technology

- Prof. Limin Wu*, The Advanced Coatings Research Center of Ministry of Education of China and Department of Materials Science, Fudan University, Shanghai, PR China, Preparation and Properties of Self-cleaning Coatings based on Poly(fluoro)siloxane/TiO2 Nanocomposites

- Te-Hui Wu, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven Netherlands, Conductive composite coatings; an alternative for corrosion inhibition on aluminium alloys

- * At the COSI conference are two kinds of speakers: invited speakers and regular speakers. Invited speakers have been put forward by one or more of the committee members and are exempted from the paper selection procedure. Invited speakers are still obliged like the committee members to pay the full fee. Regular speakers have submitted a paper to be considered for presentation by the committee members. Regular speakers will be informed of their selection in February 2012. They also are obliged to pay the full fee. COSI only supports reduced fees for students if they either present a poster or give a lecture. Note: There is only a total of 34 lecture spaces of wich ~10 are reseverd for invited speakers.

Mina Abdolah Zadeh

Novel Aerospace Materials Group, Faculty of Aerospace Engineering, Delft University of Technology, Delft, The Netherlands

Title lecture

Corrosion Trigerred Self-healing Sol-Gel Coatings

Authors

M. Abdolah Zadeh, S.J Garcia, S. van der Zwaag

Abstract

Application of organic or inorganic coatings is one the most reliable routes for corrosion protection of metallic substrates due to their high versatility and relative low cost. Amongst coating technologies, sol-gel coatings based on metal/metalloid alkoxides have attracted considerable interest as adhesion promotors and barrier protective coatings due to their attractive features, such as low processing temperature, ease of application, low or no volatile organic compounds (VOC´s), and potentially excellent final properties. Nevertheless, like all other passive coatings, sol-gel coatings fail to fulfill their functionalities over time due to damage and/or degradation resulting from local or general mechanical and chemical attacks.

The need for increasingly sophisticated high-value coatings for improved performance during service life has boosted research on self-healing coatings, which are coatings that are able to repair under external or internal stimuli the desired functionality of the coating itself [1].

Current sol-gel coatings are fully cross linked into 3D networks aiming primarily at providing barrier protection. Due to the fully crosslinked nature, no healing of local mechanical damage due to reflow of material to the scratch can occur. For the existing sol-gel coating systems only some functional self healing (i.e. healing of the corrosion protection) can be obtained by inclusion of corrosion inhibitors [2].

In the current work, we focus on the properties of the newly designed partially cured sol-gel coating systems which are capable of healing both superficial scratches and interfacial defects while restoring corrosion protection. A unique feature of our new coatings is the use of corrosion products and the metallic character of the substrate at the damaged sites to trigger and promote the healing process.

FTIR spectra has been used as a qualitative measure of the presence of hydrolyzed and polycondensed molecules in the partially cured coating. In addition the thermal stability of the systems has been characterized using thermogravimetric analysis (TGA). In order to study flow and reactivity properties of the developed coatings over time, the systems applied on glass and aluminium alloy AA2024 substrates have been scratched using a micro-starch tester and then exposed to different media. The healing behavior of the systems was monitored using confocal micoroscopy. In addition, the corrosion protection is characterized using the usual electrochemical techniques. Combination of different characterization techniques have provided complementary information on the effect of the degree of curing/cross linking on healing behavior of the developed sol-gel coatings.

References

- S.J. Garcia, H.R. Fischer, and S. van der Zwaag, Progress in Organic Coatings, 2011,3, 211-221.

- S. Zheng, and J. Li, Journal of Sol-Gel Science and Technology, 2010, 2, 174-187.

Dr. Ingo Alig

Deutsches Kunststoff-Institut, Darmstadt, Germany

Title lecture

Film formation, curing and properties of carbon nanotube-modified coatings for aircraft applications and electrical industry

Authors

Ingo Alig, Harald Oehler, Dirk Lellinger, Christian Seidel, Daniel Rudhardt, Oliver Pyrlik, Andreas Hebestreit, Manfred Suppa, Jürgen Steinwandel and Wilhelm Wulbrand

Abstract

For aircraft applications (e.g. lightweight design) and electrical industry, there is an increasing need for conductive and antistatic coatings, for instance to protect safety-relevant structural elements in aircrafts or wind energy plants made of fibre composites against lightning strokes. The research project presented combines different companies and institutes along the production as well as the knowledge chain to develop carbon nanotube-modified coatings for this purpose. Similar coating systems are developed for potential equalization in electro technical equipment (motors, generators). In order to achieve this goal, carbon nanotubes (CNT) and other particles are dispersed in PU- and epoxy-based coatings.

It is well known that the final properties of a coating depend on the one hand on the composition (polymer matrix, fillers and additives and its distribution) and on the other hand on processing (coating application), film formation and/or curing conditions. To achieve optimum properties, it is necessary to understand the structure formation and the development of the relevant electrical and mechanical properties in this process.

Therefore, we used a recently developed combined electrical and ultrasonic [1-3] setup for simultaneous time-resolved measurements of electrical conductivity and mechanical modulus during film formation and/or curing. Results for water-based reactive PU systems and thermosetting epoxy systems containing CNT are presented. The results of the time-resolved measurements are compared with the electrical and mechanical properties of the final coatings, its electric strength and resistance against lightning strokes. The results are discussed in terms of film formation [4] and curing kinetics (see [3] and references), CNT agglomeration [4, 5], electrical percolation (see [6] and references) and phase separation.

References

- I. Alig, D. Lellinger, J. Sulimma, S.Tadjbakhsch, Rev. Sci. Instrum. 68 (1997) 1536.

- I. Alig, H. Oehler, D. Lellinger, S. Tadjbach, Progr. Org. Coatings. 58 (2007) 200.

- I. Alig, P.A.M. Steeman, D. Lellinger, A.A. Dias, D. Wiencke, Progr. Org. Coatings. 55 (2006)88.

- J. Keddie, A.F. Routh, Fundamentals of Latex Film Formation: Processes and Properties,Springer.

- R. Schueler, J. Petermann, K. Schulte, H.P. Wentzel. Macromol. Symp. 104 (1996) 268.

- S. Pegel, P. Pötschke, G. Petzold, I. Alig, S.M. Dudkin, D. Lellinger. Polymer. 49 (2008) 974-984.

- I. Alig, P. Pötschke, S.M. Dudkin, I. Alig, Polymer 44 (2007) 5023-5030.

Worawan Bhanthumnavin

Department of Chemistry, Faculty of Science, Chulalongkorn University, Bangkok, Thailand

Title lecture

Aromatic phosphorodiamidate curing agent for epoxy resin coating with flame-retarding properties

Authors

W. Bhanthumnavin, B. Paosawatyanyong, I. Jirasutsakul

Abstract

An organophosphorus-based diamine containing aromatic moieties has been synthesized and used as a curing and flame retarding agent for epoxy resin coatings. This agent functions not only as a crosslinking materials in the Epon 828 epoxy resin curing process but also as a fire retarding compound to produce thin films or composites upon curing. Phenyl phosphonic p-phenylene diamine diamide was synthesized via condensation of phenylphosphonic dichloride (PPDC) and p-phenylenediamine (PDA). Kinetics studies of the curing reaction of the phosphorodiamidate were carried out in comparison with the non-P containing PDA reference crosslinking agent. Thermal stability of the cured epoxy were investigated by TGA and DSC. Moreover, flame retardant properties of the materials was investigated by LOI measurements and the UL-40 method. The results show that epoxy resin cured with phosphorodiamidate possesses higher thermostability than the counterpart. This is evident by higher amount of char formed upon burning. More importantly, the LOI of 31 was observed in the phosphorodiamidate-cured epoxy resin compared with LOI of 21 of PDA-cured epoxy resin. The UL-94 highest rating of V-0 materials were obtained with only about 2-3 wt% of the P.

Zbigniew Boncza-Tomaszewski

Industrial Chemistry Research Institute, Department of Polyesters, Epoxides and Polyurethanes, Warszawa, POLAND

Title lecture

New toxicologically-safe cross-linkers for powder coatings

Authors

Z. Boncza-Tomaszewski, M. Kedzierski, K. Rucinska, A.Niska

Abstract

The expansion of powder coatings for exterior use is affected by the mutagenity triglycidyl isocyanurate (TGIC). Due to the toxicity this hardener is frequently substituted by β-tetrahydroxy alkyl diamid, known as Primid which can be considered non-toxic. Curing with Primid represents, however, a polycondensation reaction, with water as a byproduct, which causes frequently coating failures and defects. Therefore, there is an intense demand for alternative cross-linkers materials, which are non-toxic, which can be produced environmentally compliant and which cure without formation of by-products. Novel cycloaliphatic diepoxide based on dicyclopentadiene are evaluated as cross-linkers for polyester powder coatings. These diepoxides were synthesized in two step process from hydroxyl-dihydrodicyclopentadienyl and diisocyanates (TDI and IPDI) followed by the epoxidation reaction. The properties, handling characteristics and performance of aliphatic epoxide based powder coating systems are discussed.

Dr. Elisa Campazzi

EADS Innovation Works, Metallic Technologies and Surface Engineering, Suresnes, France

Title lecture

Alternatives to Chromate Systems for Corrosion Protection in Aerospace: Study of "Green"-Inhibitor Loaded Spheres in Model Sol-Gel Coatings

Authors

E. Campazzi, M. Villatte, C. Druez, S. Senani, C. Barbé

Abstract

This work fits with current research programs running within EADS Innovation Works (IW) on the assessment of smart Cr-free protection concepts and, in particular, on hybrid sol-gel systems for protection before paint of aluminium alloys. In this project, carried out in collaboration with CeramiSphere Pty Ltd (http://www.ceramisphere.com), we explored the potential of environmentally friendly corrosion inhibitors entrapped in sol-gel made spheres (using CeramiSphere's technology [1]) which enable the controlled release of the inhibitor. The work jointly performed by EADS IW and Ceramisphere concerns the characterization and the assessment of performance of aluminium samples, coated by spraying with a glycidoxypropyltrimethoxysilane (GPTS) aqueous solution, including different kinds of Ceramispheres loaded with one organic inhibitor, and focuses in particular on two main topics:

- the incorporation of Inhibispheres™ (IS) in coatings

- the coatings characterization and the comparison of their performances.

Gary Craun

Global Research, AkzoNobel Packaging Coatings, Strongsville, Ohio, USA

Title lecture

Polyols and water boren acrylic grafted polyetheer polyols synthesized with epoxidized soy bean oil

Authors

Gary Craun

Abstract

Epoxidized soy bean oil can be reacted with alcohols and glycols in the presence of a strong acid catalyst, such as triflic acid, to produce polyether polyols. Epoxy to hydroxyl ratios can be controlled to produce polyether polyols with 30,000 Mn that thermally cure with conventional cross linkers to form coatings with good resistance properties. Polyether polyols based on epoxidized soy bean oil and propylene glycol can be grafted with acrylic monomers to produce water borne copolymers with particle sizes in the 100 nm range.

Dr. Marc Entenmann

Fraunh. Inst. for Manufacturing Engineering and Automation

Title lecture

Monitoring of degradation process in automotive - multilayer coatings using photooxidation index

Authors

M. Entenmann, D. Koch, H. Greisiger, T. Schauer

Abstract

The photooxidative degradation of e-coats in different automotive multilayer coating systems was investigated by performing photooxidation index (POI) measurements using a FT-IR-microscopic device. For the photoxidation index measurements a special flat cutting was developed and the measurements were performed on the original and the corresponding weathered multicoat systems. The obtained POI results were compared with the corresponding UV-VIS-NIR transmittance and absorption data and finally the influencing parameters of photochemical degradation processes were discussed. The obtained results prove that the transmittance of UV-light is not the only important parameter which influences the degradation stability of the e-coat and thermocatalytic effects, which accelerate the photooxidation process, should be regarded.

Céline Falentin

Center for Education and Research on Macromolecules (CERM), Chemistry Department, University of Liège, Sart-Tilman B6a, 4000 Liège, Belgium

Title lecture

A water-based antibacterial nanohybrid solution for coating stainless steels

Authors

Céline Falentin-Daudré, Emilie Faure, Tiziana Svaldo-Lanero, Cécile Van De Weerdt, Joseph Martial, Catherine Archambeau, Anne-Sophie Duwez, Christine Jérôme and Christophe Detrembleur

Abstract

Due to its exceptional properties, stainless steel (SS) is widely used in the daily life (food industry, household appliances, surgery …). However, it is unable to prevent bacteria from adhering, proliferating and forming a resistant biofilm when ageing. Therefore, surface modification is needed for providing durable antibacterial properties. Very recently, we reported on an all-in-one approach to prepare refillable antimicrobial films [2] using the layer-by-layer (LbL) deposition of polyelectrolytes. Specifically designed biocidal multilayered polyelectrolyte films that bear 3,4-dihydroxyphenylalanine (DOPA), known as a promoter of adhesion to inorganic surfaces, were deposited onto SS. DOPA was incorporated in the polycationic chains by radical copolymerisation of N-methacrylated DOPA with the quaternary ammonium salt of 2-(dimethylamino)ethyl methacrylate (DMAEMA+). In order to boost the antibacterial activity of the polycationic layer, AgNO3 was added to the aqueous solution of P(DOPA)-co-P(DMAEMA+), which resulted in the in-situ formation of silver based nanoparticles, sources of biocial Ag+. The layer-by-layer deposition of aqueous P(DOPA)-co-P(DMAEMA+)/AgCl/Ag0 suspension and aqueous solution of poly(styrene sulfonate) provided high antibacterial activity against Gram-negative E. Coli bacteria. Although this surface modification is highly efficient, it requires the LBL deposition of about 60 bilayers that makes the process difficult to scale-up. In the present communication, we will demonstrate how the same copolymers can impart AB properties to the SS surface using only 1 or 2 layers.[3],[4] Novel nanohybrids are first formed in water before being deposited on the surface. The method of formation of these nanohybrids, their deposition and the characterization of the modified surface will be discussed in detail in this talk. This novel "water-based" approach is convenient, simple and is promising for scalable applications. It might also be used for coating other organic and inorganic surfaces in order to impart them AB properties.

Acknowledgements

The research was partly supported by BELSPO in the frame of IUAP VI/27 and Région Wallonne, ArcelorMittal and ULg through the PPP program BIOCOAT. C.D. is "Maître de Recherche" of the F.N.R.S. (Belgium), and thanks the F.R.S.-F.N.R.S. for financial support.References

- J. A. Helsen and H. J. Breme, in Metals as Biomaterials, Wiley, New York, 1998.

- A. Charlot, V. Sciannamea, S. Lenoir, E. Faure, R. Jerome, C. Jerome, C. Van De Weerdt, J. Martial, C. Archambeau, N. Willet, A.-S. Duwez, C.-A. Fustin, C. Detrembleur, Journal of Materials Chemistry 19, 4117-4125, 2009.

- E. Faure, P. Lecomte, S. Lenoir, C. Vreuls, C. Van De Weerdt, C. Archambeau, J. Martial, C. Jérôme, A.-S. Duwez and C. Detrembleur, J. Mater. Chem., 2011, 21, 7901-7904.

- C. Falentin-Daudré, E. Faure, T. Svaldo-Lanero, F. Farina, C. Jerome, C. Van De Weerdt, C., J. Martial, A.-S. Duwez and C. Detrembleur, Langmuir, accepted.

Vanesa García-Pacios

Adhesion and Adhesives Laboratory, University of Alicante, Alicante, Spain

Title lecture

Incidence of the polyol nature used in the synthesis of waterborne polyurethane dispersions intended for use as coatings

Authors

Vanesa García-Pacios, Manuel Colera, Yoshiro Iwata, José Miguel Martín¬Martínez

Abstract

There are few scientific studies dealing with the synthesis and characterization of waterborne polyurethane dispersions (PUDs) obtained with polyols of different nature intended as coatings for wood and metallic substrates. In this study several waterborne polyurethane dispersions obtained with polyester, polyether and polycarbonate diols of similar molecular weight were prepared by using the acetone method and their properties as coatings on stainless steel were measured. The structure and properties of the polyurethane coatings were influenced by the polyol nature. The polyurethanes obtained with polyether or polyester polyol showed higher degree of phase separation between the soft and hard segments than for the polyurethane obtained with polycarbonate diol. The properties of the polyurethane coating obtained with polycarbonate diol were significantly less affected after thermal degradation and weathering as compared with those of the polyurethane coatings prepared from PUDs synthesized with polyether or polyester diols likely due to the high stability of the carbonate groups.

Dogan Gunbas

Laboratory of Polymer Chemistry, Eindhoven University of Technology, Eindhoven, The Netherlands

Title lecture

PDMS-modified poly(styrene-alt-maleic anhydride) as waterborne coating based on surfactant-free latex

Authors

I.D. Gunbas, M.E.L. Wouters, M.M.R.M. Hendrix, R.A.T.M. van Benthem, C.E. Koning, B.A.J. Noordover

Abstract

In this paper we report the modification of poly(styrene-alt-maleic anhydride) (PSMA) with monofunctional amine-terminated polydimethyl siloxane (PDMS-NH2) by thermal imidization, followed by the preparation and characterization of a surfactant-free artificial latex thereof and application of this latex onto cotton fabric. The imidization reaction was monitored by NMR and attenuated total reflection Fourier transform infrared (ATR-FTIR). 1,2-cyclohexyldicarboxylic anhydride (CDA) was chosen as a model compound for the PSMA copolymer, allowing a more detailed characterization by NMR and ATR-FTIR. After the PSMA/PDMS-NH2 imidization reached completion, a fraction of the anhydrides were ammonolyzed. In this way, a self-emulsifying latex with an average particle diameter of approximately 145 nm and a ζ-potential of -56 mV was obtained. It was found that the PDMS-modified PSMA latex (PSMA30) is stable in the pH range of 4-10. The water contact angle values of the latex-coated cotton textile fabric indicate a hydrophobized surface, with a static contact angle of 135.7°± 1.2°. The washing studies with a standard soap solution of the cotton samples with or without crosslinker showed that the crosslinked PSMA30 offers a good coating durability on the cotton. This waterborne resin based on surfactant-free latices displays promising properties for coating applications and seems to be very suitable for the hydrophobization of polar surfaces.

Assist.Prof. Mogens Hinge

Dept. of Eng. Aarhus University, Aarhus, Denmark

Title lecture

Organic coatings based on aryldiazonium salts

Authors

M. Hinge, S. U. Pedersen, K. Daasbjerg.

Abstract

This paper demonstrates the generation of, covalent attached, organic coatings via the versatile and simple aryldiazonium salt method. Examples are shown on how to; generate thick and thin organic films, apply the layer as a precursor for subsequent reactions, as well as the thermal stability of the generated layers.

Dr. Maude Jimenez

UMET, équipe ISP-PERF, CNRS UMR 8207, Université Lille Nord de France, ENSCL, Villeneuve d´Ascq cedex, France

Title lecture

Protective coatings for reaction and resistance to fire of materials

Authors

M.Jimenez, S.Duquesne, S.Bourbigot.

Abstract

The use of fire protective coatings is one of the easiest, one of the oldest and one of the most efficient ways to protect a substrate against fire. Indeed, it presents several advantages: it does not modify the intrinsic properties of material, it is easily processed and can also be used on diverse materials. Among the various types of fire protective coatings, intumescent coatings constitute one of the most efficient one and will be used to protect different substrates (steel and polymers) in the first and second parts of this paper. First, the mechanism of action of the basic ingredients of an intumescent formulation designed to protect steel in severe fire conditions are described. We showed that the combination of ammonium polyphosphate and boric acid in epoxy resins allows obtaining an efficient protection in hydrocarbon fire conditions. The second part details an innovative way to protect polymers exposed to fire, since they are, usually fire retarded in the bulk. We show that a good level of protection can also be achieved using coating, and in particular a waterborne intumescent varnish. In the last part, another type of fire protective coating will be presented. Indeed, we will detail the efficiency in terms of fire resistance of a very thin organosilicon layer coated by cold plasma on high performance non-wovens.

Prof.Dr. Joseph L. Keddie

Department of Physics, University of Surrey, Guildford, Surrey, UK

Title lecture

Bespoke Patterned Coatings via Infrared Radiation-Assisted Evaporative Lithography

Authors

J.L. Keddie, A. Georgiadis, M. Hinton, M.W. Murray, and A. F. Routh

Abstract

Abstract Polymer coatings with periodic topographic patterns, repeating over millimetre length scales, are created from lateral flows in an aqueous dispersion of colloidal particles. The flow is driven by differences in evaporation rate across the wet film surface created by IR radiative heating through a shadow mask. This new process, which we call IR radiation-assisted evaporative lithography (IRAEL), combines IR particle sintering with the concept of evaporative lithography. We show that the height of the surface features increases with an increase in several key parameters: the initial thickness of the film, the volume fraction of particles, and the pitch of the pattern. The results are interpreted by using models of geometry and particle transport. The patterned coatings can function as "paintable" microlens arrays, applicable to nearly any surface. Compared with existing methods for creating textured coatings, IRAEL is simpler, inexpensive, able to create a wide variety of bespoke surfaces, and applicable to nearly any substrate without prior preparation.

Assist.Prof. Søren Kiil

Department of Chemical and Biochemical Engineering, Technical University of Denmark, Lyngby, Denmark

Title lecture

Quantitative analysis of photoinitiated coating degradation at constant artificial exposure conditions

Authors

Søren Kiil

Abstract

This work concerns the development of simulation tools for mapping of degradation phenomena and estimation of mass loss and ablation rates during weathering tests of thermoset coatings. A novel mathematical model, which includes photoinitiated oxidation reactions, intrafilm oxygen permeability, water absorption and diffusion, reduction of crosslink density, and development of a thin surface oxidation zone, was recently developed. The model has been validated against three previous experimental data series with two-component epoxy-amine coatings at constant exposure conditions. One data series includes the effect of nano-particles (SiO2 and multi-walled carbon nano-tubes) on the rate of degradation. In this presentation, a concise introduction to the model and some of the simulation results are provided. Further development of the simulation tool to commercial coatings and dynamic exposure conditions will be shortly discussed.

Prof.Dr. Cor Koning

Laboratory of Polymer Chemistry, Eindhoven University of Technology, Eindhoven, the Netherlands / DSM Coating Resins, Zwolle, the Netherlands

Title lecture

Novel coating resins based on poly(ester)carbonates made by catalytic chain growth polymerization of epoxides, anhydrides and CO2

Authors

C.E. Koning, R.S. Sablong, Elham Hosseini Nejad, R. Duchateau

Abstract

Powder coating resins polyesters are usually synthesized from monomers like terephthalic acid, isophthalic acid, trimellitic anhydride, neopentylglycol and trimethylolpropane by a straightforward step-growth polymerization process. Here we describe a possibly new generation of powder coating resins of the polycarbonate or poly(ester)carbonate type, synthesized fom epoxides like cyclohexene oxide (CHO), phthalic anhydride and carbon dioxide by chain growth polymerization processes. The chain growth process was catalyzed by a chromium2Salophen complex and dimethylaminopyridine (DMAP) was used as a co-catalyst. The polymers produced were carefully molecularly characterized and especially MALDI-ToF MS yielded important information on the end-groups which are crucial for the curing chemistry of these resins. One special type of copolycarbonate carried pendant vinyl groups, introduced by copolymerization of CHO and CO2 with 42vinylcyclohexene oxide (VCHO). This copolycarbonate was solvent casted from solution, after which the polymer was successfully cured by UV2 or thermally2induced radical curing chemistry. These cured coatings were tested for their acetone resistance and reversed falling dart impact toughness. These results look promising.

Sviatlana Lamaka

ICEMS, Instituto Superior Técnico, Technical University of Lisbon, Av. Rovisoc Pais, 1, 1049-001 Lisbon/Portugal, sviatlana.lamaka@ist.utl.pt

Title lecture

Fault-Tolerant Hybrid Epoxy Silane Coatings for Corrosion Protection of Mg Alloys

Authors

S.V.Lamaka, H. B. Xue, F. Brusciotti, D.V. Snihirova, M.F. Montemor, M.G.S. Ferreira

Abstract

Competitive composite coatings were developed for corrosion protection of magnesium alloys used in aeronautical applications. Improved performance and durability of the coating is achieved by combining an epoxy component, providing a low-defect barrier, with silane, providing good adhesion.

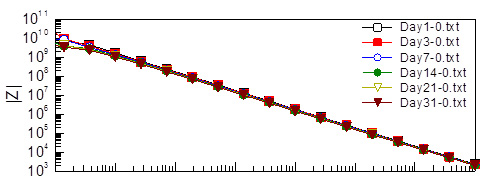

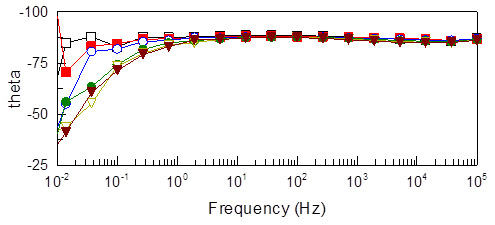

The developed hybrid epoxy silane coatings were applied, by dip-coating, to the industrially important Mg alloys: AZ31 and ZE41. The average thickness of these hybrid epoxy silane coatings is 7 to 18 micron. This thin hybrid coating provides excellent adhesion to the substrate and prevents corrosion when exposed to a 3.5% NaCl solution. The corrosion behaviour of the substrates pre-treated with hybrid epoxy silane coatings were tested using Electrochemical Impedance Spectroscopy (EIS). Figure 1 presents the evolution of the coating impedance throughout 1 month of exposure to 3.5% NaCl aqueous solution.

Figure 1, Bode diagrams of the epoxy silane coating applied to AZ31 magnesium alloy during the course of 31 days of immersion in 3.5% NaCl solution.

The coated samples showed a very high resistance to corrosion and after one-month of immersion in NaCl their performance was still very high compared to the best results shown in literature [1-4].

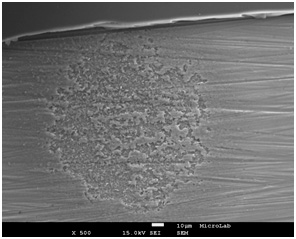

After one month of exposure, the coating was intentionally detached and small sites of corrosion were found on the magnesium substrate, Figure 2. Surprisingly for electrochemically active magnesium substrates, corrosion in these sites did not propagate.

Figure 2. SEM micrograph of the passivated corrosion site under the coating purposely detached after immersion.

To assess the resistance of the developed coating to mechanical damage, different types of defects were intentionally made in the coating. EIS, as well as Scanning Vibrating Electrode Technique (SVET) coupled with Scanning Ion-selective Electrode Technique (SIET) were used to study the behavior of the magnesium substrates with damaged coating. Even though the coatings were not impregnated with any corrosion inhibiting reagents they showed a high corrosion resistance if the coating was mechanically damaged.

The passivation mechanism of defects, be they natural (as shown in Figure 2) or artificial, is not fully understood yet. Several hypotethes will be discussed in the presentation.

Concluding, different compositions of hybrid epoxy silane coatings show enhanced long-term corrosion protection of magnesium both when the coating was intact or intentionally damaged. Such fault-tolerant coatings are of great interest for industrial applications.

Acknowledgements

Marie Curie IRSES project “SISET” GA-2010-269282 and Portuguese Foundation for Science and Technology (FCT) project PTDC/CTM-MET/112831/2009 for financial support, EADS Innovation Works, Munich, for supplying the alloys.

References

- A.N. Khramov, J.A. Johnson, Phosphonate-functionalized ormosil coatings for magnesium alloys, Prog. Org. Coat., 65 (2009) 381 – 385.

- S. Y. Zhang, Q. Li, J. ;M. Fan, W. Kang, W. Hu, X.K. Yang, Novel composite films prepared by sol-gel technology for the corrosion protection of AZ91d magnesium alloy, Prog. Org. Coat., 66 (2009) 328–335.

- H. Wang, R. Akid, M. Gobara. Scratch-resistant anticorrosion sol–gel coating for the protection of AZ31 magnesium alloy via a low temperature sol–gel route,. Corr. Sci. 52 (2010) 2565 - 2570.

- S.V. Lamaka, M.F. Montemor, A.F. Galio, M.L. Zheludkevich, C.Trindade, L.F. Dick, M.G.S. Ferreira, Novel hybrid sol-gel coatings for corrosion protection of AZ31B magnesium alloy. Electrochim. Acta, 53 (2008) 4773–4783.

Prof. Joëlle Levalois-Grützmacher

Department of Chemistry, Swiss Federal Institute of Technology, ETH Hönggerberg, Zürich, Switserland

Title lecture

Flame-retardant finishing by a low pressure plasma process on cotton textiles in combination with dyeing

Authors

Joëlle Levalois-Grützmacher, Katrin Prinz

Abstract

In the development of new flame retardant treatments for cotton fabrics the easy integration of this step in existing finishing processes is important. Any resulting change in the hue or lightness has to be taken into account in the dyeing process. Therefore, after the successful syntheses and application via the Plasma Induced Graft-Polymerization (PIGP) process of new flame retardant compounds (FR), phosphopramidates, their combination with other finishing treatments like dyeing was investigated. Dyeing experiments with reactive, vat and direct dyes after (procedure 1) or before (procedure 2) the flame retardant finishing were performed. The degree of whiteness and any colour changes were determined by means of the grey scale measurements and spectrophotometry. The flammability of the treated cotton fabrics is evaluated by LOI measurements.

Dr. Bas Lohmeijer

BASF SE, Ludwigshafen, Germany

Title lecture

Prefered partitioning: the influence of coalescents on the build-up of mechanical properties in acrylic core-shell particle

Authors

Bas Lohmeijer, Roelof Balk, Roland Baumstark

Abstract

In many formulations there is still a need for coalescents in order to get the best film formation and performance of the binder. Nevertheless, a lot of the know-how regarding coalescent selection and level is based on empirical data. Here we provide a rationale for the influence different types of coalescents have on the film formation process using dynamic mechanical analysis during the drying of such polymer films. It allows probing the development of the E-modulus of films and gives an idea to what extent the coalescent interacts with the hard phase polymer on the one hand and the soft phase on the other. The partitioning of the coalescent between the different phases has consequences for the coating's performance both during its early service life (when the coalescent has not completely evaporated, but the coating is supposed to have developed its desired properties) and in its fully-developed state.

The film formation of state-of-the-art multiphase acrylic dispersions will be presented. A few important industry tests (early water whitening resistance, early hot blocking resistance and pendulum hardness development) are described for the binders and the results are correlated to the degree of film formation of both the hard and the soft phase.

Dr. Kimihiro Matsukawa*

Electronic Material Devision, Osaka Municipal Technical Research Institute, Osaka, Japan

Title lecture

Photo-cured Organic-inorganic Hybrid Thin Films with Controlled Refractive Index

Authors

Kimihiro Matsukawa, Seiji Watase

Abstract

The different combinations of organic and inorganic components have been available in hybrid materials, which is a great potential for the electrical, optical, structural applications, etc. Especially, as the organic-inorganic hybrid thin films are optically transparent, they are useful optical materials, in which refractive index control is one of the most important properties. It is well known that organic materials with aromatic rings or sulfur element have higher refractive index. In order to prepare low refractive index hybrids, it can be achieved by forming nano porous structure. The organic-inorganic hybrids with these substances are good candidates of refractive index controllable materials. We have been investigating several types of organic-inorganic hybrids with different refractive index.

Mohor Mihelčič

National Institute of Chemistry, Ljubljana, Slovenia

Title lecture

Electrochromic TiO2 pigment coating and plastic film-based NiO/TiO2 device with transmissive light modulation

Authors

M. Mihelčič, I. Jerman, B. Orel

Abstract

Thin (100-400 nm) electrochromic TiO2 coatings providing transmissive light modulation were made from an anatase pigment dispersion obtained by co-grinding nanocrystalline titania particles (6-10 nm in size) with trisilanol heptaisobutylsilsesquioxane as dispersant. Dispersions were obtained by milling the anatase pigment with zirconia beads of different sizes (0.1, 0.2 and 0. 4 mm). After the addition of titanium tetraisopropoxide, the dispersion was deposited by spin-coating on glass and plastic (PET) film and thermally treated at 150 °C to obtain thin TiO2 coatings. TEM and EDX investigations revealed the presence of dispersant surrounding the anatase particles, enabling a dispersion with a uniform distribution of particles (particle size 50-70 nm). SEM and AFM were used for determination of surface morphology, showing their homogenous structure and low surface roughness (up to 20 nm). The optical transmittance and haze of the coatings deposited on glass and PET film were determined from the UV VIS spectra. Their electrochromic effect was analyzed by electrochemical charging/discharging the coatings in LiClO4/PC electrolyte. The results demonstrated a convenient, simple and robust technique for making “electrochromic paint” coatings. Pre-prepared TiO2 and NiO pigment were used for construction of plastic film based electrochromic devices with transmissive modulation of light.

Karuppiah Murugan

International Advanced Research Center for Powder Metallurgy and New Materials, Hyderabad, India

Title lecture

Synthesis, characterization and demonstration of self-cleaning TiO2 coatings on glass and glazed ceramic tiles

Authors

K. Murugan, R. Subasri, T. N. Rao, Ashutosh S. Gandhi, B.S. Murty

Abstract

An effort was made not only to demonstrate the performance of the self-cleaning coatings on building materials such as ceramic glazed tiles and glass windows, but also to understand the fundamental issues that are still alive in the field of self-cleaning surfaces based on photocatalysis. Nano TiO2 transparent thin films were generated by dip, spray and flow coating method. The effect of dehydration rate due to hydrolysis in a non hydrolytic sol-gel process was investigated. The present results indicate that the inconsistent results in the self-cleaning studies may be due to the effect of aggregation of model pollutant (methylene blue) dye on TiO2 surface. The effect of aliovalent metal ion (Ni2+, Fe3+, Nb5+) doping on phase formation, polymorphic transition, visible light absorbance and optical transparency of TiO2 film were investigated using x-ray diffraction (XRD), x–ray photoelectron spectroscopy (XPS) and UV visible absorption spectroscopy. The improved visible light activity of doped TiO2 thin film was correlated to the Ti(Ni/Fe)O3 phase formation, UV and visible light absorbance, variation in the optical energy band gap and the probable light scattering associated with grain size.

Dr. Yutao T. Pei

Materials innovation institute M2i, Department of Applied Physics, University of Groningen, Groningen, The Netherlands

Title lecture

Flexible protective diamond-like carbon films on rubbers

Authors

Y.T. Pei, X.L. Bui, J.P. van der Pal, D. Martinez-Martinez, J.Th.M. De Hosson

Abstract

Dynamic rubber seals are major sources of friction of lubrication systems and bearings, which may take up to 70% of the total friction. The solution we present is to coat rubbers with diamond-like carbon (DLC) thin films by which the coefficient of friction is reduced to less than one tenth. Coating rubber is very challenging because the film must be flexible and strongly adhered to rubber surface. Here we present and discuss our novel approach by depositing flexible DLC films on various rubbers via self-segmentation. By making use of the substantial thermal mismatch between DLC film and rubber substrates a dense crack network forms in DLC films and contributes to flexibility. The size of film micro-segments can be tuned by varying the bias voltage of pulsed-DC plasma CVD, which governs the amplitude of the substrate temperature variation during deposition. An analytical model is developed to predict the crack spacing and the result fits well to the measured data. The formation mechanism of crack network and its effect on the flexibility and friction of DLC film coated rubbers are scrutinized. This paper provides generic design rules for the deposition of flexible and ultra-low friction DLC films on rubber seals.

Dr. Alexander Routh

BP Institute for Multiphase Flow & Department of Chemical Engineering and Biotechnology, University of Cambridge, Madingley Rise, Cambridge.UK

Title lecture

Evaporation mediated self assembly of nanoparticles: Watching paint dry

Authors

Alexander Routh

Abstract

Drying dispersions are observed to display a number of homogeneities. There are well known horizontal drying fronts passing laterally across films that induce pressure gradients, resulting in cracking and wrinkling. Vertical in-homogeneities are also often seen with skin formation a common occurrence in film formation. This talk will describe a number of these inhomogeneities. In the horizontal drying case we will concentrate on film cracking and examine a wiggly crack instability. For larger films the occurrence of vertical auto stratification will be examined. For two component systems it is possible to get composition stratification with one component preferentially migrating to the top surface. The controlling factors are the particle size, setting the diffusion rate, as well as any surface chemistry driving stratification. We have applied a diffusional model to a number of systems and used a range of experimental techniques such as AFM, confocal microscopy and MRI imaging.

Dr. Eriko Sato

Department of Applied Chemistry and Bioengineering, Graduate School of Engineering, Osaka City University, Osaka, Japan

Title lecture

Reversible Volume Changes of Polymer Thin Films and Their Application to Wettability Control

Authors

Eriko SATO, Sayoko NAGAI, Akikazu MATSUMOTO

Abstract

Surface wettability is one of the most important surface properties and affected by not only surface free energy but also surface topography. We have focused on the volume shrinkage of polymers associated with cross-linking as a tool to control surface topography and conceived that the patterning of the cross-linked area on the surface would enable to control surface topography. In this study, polymers and reaction conditions enabling the reversible volume changes by cross-linking and de-cross-linking were revealed and applied to photo patterning. The photo patterning of a shrinkable polymer resulted in an indented patterned surface and an effective increase in the contact angle of water compared to the case of a non-shrinkable polymer.

Prof. dr. ing. Wilhelm Schabel

Karlsruhe Institute of Technology, Thin Film Technology, Germany

Title lecture

Drying of Thin Films –structure and morphology formation with processing related aspects

Authors

Wilhelm Schabel

Abstract

In many thin film applications such as organic electronics, biosensors, optical coatings and battery layers there is a growing demand for functional layers with particular morphologies, highly homogeneous surface topologies, multilayer structures and desired structure-process properties. The thickness of these layers is in the range of 10 nm to 10 µm with often very limited accepted deviations of final coating properties. Drying and processing conditions can affect the resulting functional coating in many aspects such as life time performance of battery coatings, surface properties of organic electronics, morphology and efficiencies of semiconducting organic layers. Recent results (details can be found in refence [1] –[6]) of research on this related topics will be presented in this contributions in an oral talk as highlighted summary.

References

- B. Schmidt-Hansberg, M. F.G. Klein, M. Sanyal, F. Buss, G. Q. G.de Medeiros, C. Munuera, A. Colsmann, P. Scharfer, U. Lemmer, E. Barrena and W. Schabel, Structure formation in high temperature drying processes of low-band gap polymer:fullerene solar cell blends, submitted to Advanced Functional Materials, submitted 04/2012

- B. Schmidt-Hansberg, M. Sanyal, N. Grossiord, Y. Galagan, M. Baunach, M.F.G. Klein, A. Colsmann, P. Scharfer, U. Lemmer, H. Dosch, J. Michels, E. Barrena, W. Schabel, Investigation of non-halogenated solvent mixtures for high throughput fabrication of polymer-fullerene solar cells, Solar Energy Materials and Solar Cells 96, 195-201, 2012

- P. Cavadini, J. Krenn, P. Scharfer and W.Schabel, Investigation of surface deformation during drying due to Marangoni-convection. Part I: In situ reconstruction of the surface, Chemical Engineering and Processing, submitted 04_2012

- S. Kachel, Y. Zhou, P. Scharfer, W. Schabel, Drying behavior of waterborne polymer mixtures for biosensor films, Chemical Engineering and Processing, submitted 2012

- P. Cavadini, D. Sachsenheimer, D. Garella, A. Kowalczyk, N. Willenbacher, J. Krenn, P. Scharfer and W. Schabel, Investigation of surface deformation due to Marangoni convection. Part II: Flow field visualization. Chemical Engineering and Processing, submitted 03_2012

- M. Müller, P. Scharfer, M. Kind, W. Schabel, Influence of Non-Volatile Additives on the Diffusion of Solvents in Polymeric Coatings, Chemical Engineering and Processing 50, Issue 5-6, 551 - 555, 2011

Artur Siwek

ABB Corporate Research Center, Starowislna 13A, 31-038 Krakow, Poland

Title lecture

Adhesion of epoxy resin to a low friction coatings and its correlation with tribological properties

Authors

A. Siwek, A. Michalik, A. Rybak

Abstract

The purpose of this study was to investigate the adhesion force of epoxy resin to low friction coatings and its relation to the tribological properties of selected coatings as compared with non coated stainless steel. Seven commercially available coatings with coefficient of friction below 0.5 were prepared on the stainless steel substrates. The adhesion to epoxy was investigated by casting epoxy onto the coated surface and measuring force necessary to separate cured epoxy from the sample. The hardness, Young modulus, coefficient of friction in two systems and wear coefficient were measured to characterize the tribological properties of studied coatings. Additionally the surface was inspected with optical microscope and profilometer.

Dr. Mark D. Soucek

Department of Polymer Engineering, University of Akron, OH, USA

Self-Stratifying Coatings

Authors

M. D. Soucek, E. Alyamac, H. Gu

Abstract

A series of BPA-type epoxide primers and acrylic topcoats were prepared as a homogeneous solution in several solvents. The miscibility of the BPA-epoxide with the acrylic was adjusted by either polar or non-polar modification of the epoxide (phosphate ester, fatty acid ester, or tetraethoxysilane). The acrylic topcoat was consisted of methyl methacrylate (MMA), butyl acrylate (BA), 2-hydroxyethyl methacrylate (HEMA), and 0-10 wt% 2,2,2-trifluorehtyl methacrylate (TFEMA). The primer and a topcoat were applied in a single coating application and crosslinked with an melamine-formaldehyde resin (M-F). The stratification of the films was evaluated by XPS and SEM-EDAX. The stratification of the two polymeric binder systems was dependent primarily on both the polymer-polymer miscibility and chemical potential driving force their respective interface. When the primer and topcoat were miscible and there was no driving force to the interface a homogenously mixed system was observed. When the primer and topcoat was miscible and there was a driving force toward the interface, an enhancement of the primer at the film-substrate (F-S) interface, and topcoat at the film-Air (F-S) interface was observed. The bulk of the coating, however, was relatively homogenous. When the polymeric binders were not miscible and there was a chemical potential to drive each of the polymers to their respective interface, a stratification was observed where the primer was concentrated from the F-S upward into the bulk film, and the topcoat was stratified downward from the F-A interface. In effect, application of a single coating was shown to replace two separate coating processes.

Dr. Thomas Stimpfling

Laboratoire des Matériaux Inorganiques, UMR CNRS 6002, Université Blaise Pascal, AUBIERE, France

Title lecture

EDTA interleaved LDH as efficient epoxy coating pigment for Aluminium corrosion protection

Authors

Thomas Stimpfling, Fabrice Leroux and Horst Hintze-Bruening

Abstract

The development of chromate alternative for the corrosion protection of aluminium substrates is still topical in the coatings community to yield more environmental friendly coatings. To respond to this concern the concept of corrosion inhibitors entrapped within a host matrix is of great interest since it allows its progressive release under stimuli without deteriorating the coatings barrier function. Layered Double Hydroxide (LDH) has been chosen as a container for corrosion inhibitor agents that potentially provide a diffusion barrier due to the platelets high aspect ratio. Ethylenediaminetetraacetic acid (EDTA) was selected as the corrosion inhibitor which was intercalated via the coprecipitation route. This presentation gives in a depth characterization of the inorganic organic (I/O) hybrid assembly and results from an evaluation of the corrosion inhibition efficiency in presence of aggressive anion and in comparison to chromate, carbonate and chloride bearing LDH containers. The mechanism of inhibitor release is studied by X-Ray diffraction and its efficiency as a filler in an epoxy coating was followed by Electrochemical Impedance Spectroscopy (EIS) and DC-Polarization experiments (Tafel plots refinement). The corrosion protection was scrutinized against electrolyte salt concentration and versus exposure time. The accuracy and the reproducibility of the evaluation methods are discussed.

Assoc. Prof. Shujuan Tan

College of Material Science & Technology, Nanjing University of Aeronautics and Astronautics, Nanjing, PR China

Title lecture

Preparation and properties studies of paraffin/high density polyethylene composites and phase-change coatings

Authors

Shujuan Tan, Shujuan Yu, Guoyue Xu, Yachen Zhang

Abstract

The form-stable paraffin/high density polyethylene (HDPE) composites and phase-change coatings were prepared and characterized in this study. The paraffin acts as thermal absorbing material and HDPE serves as the supporting material, which provides structural strength and prevents the leakage of melted paraffin. Scanning electronic microscope (SEM) observed that the paraffin dispersed uniformly into porous network of HDPE. Differential scanning calorimeter (DSC) determined the melting temperature and heat storage capacity of the composite to be 51.2°C and 150.88kJ/kg, respectively. Moreover, Results indicated that the composite pieces showed better thermal stability than composite powders after 6 temperature cycling experiments. The phase-change coatings with 40wt% composites as functional filler showed good adhesion strength and shock resistance, and could decrease the surface temperature by 12°C comparing with nude Al alloy plates.

Madeleine Tchoquessi Diodjo

Université du Sud Toulon Var, France,

Title lecture

Influence of silane-based treatment on adherence and wet durability of fusion bonded epoxy/steel joints

Authors

M. Tchoquessi, E. Aragon, L. Belec, Y. Joliff, F.X Perrin, Stéphane Hertz-Clemens, Lise Lanarde, Michel Meyer

Abstract

Three layers polyolefins coatings are widely used in Europe to protect pipelines against corrosion. It is a multilayer system that associates an epoxy primer, a modified polyolefin adhesive and a polyolefin topcoat. Nevertheless, loss of adhesion at epoxy/steel interface has been observed even on pipelines without external defects. Silane-based surface pre-treatments are developed to improve adhesion with limited impacts on the environment unlike usual chromate conversion pre-treatments; however the mechanisms involved in silane action need to be more deeply understood. The application process implies a series of key parameters which optimisation is imperative to form a silane layer with good properties at the interface. Thus, this paper studies the influence of the curing conditions of a silane based pre-treatment on adhesion strength and durability via single lap shear tests. The influence of pH is also investigated after selecting the best curing conditions. FT-IR, XPS and SEM/EDAX analysis are used to analyse the surfaces at initial state and after ageing. A comparative analysis is made with the conventional system without pre-treatment before and after hydrothermal ageing

Jesús .M. Vega

Material innovation institute, Delft, The Netherlands / Novel Aerospace Materials Group, Faculty of Aerospace Engineering, Delft University of Technology, Delft, The Netherlands.

Title lecture

Ionomers as self-healing coatings for metal protection

Authors

J.M. Vega, S.J. Garcia, S. van der Zwaag

Abstract

Coated steel and coated galvanized steel wires are commonly used in applications as different as fences and bras. Despite their differences, they share the need of extended corrosion protection of the metal substrate under severe conditions. As long as the protective organic coatings are intact, the long term protection can be guaranteed except at the cut wire ends at which the base metal is exposed. The unprotected cut edge can easily corrode, even when a galvanizing layer is applied. The cathode-anode area ratio is so high that localized corrosion starts leading to a complex phenomenon known as cut-edge. It may result in undermining the galvanic zinc layer and also in promoting coating delamination.

The implementation of self-healing concepts [1] to coated wires could extend the service lifetime at cut edges. Amongst all self-healing concepts used in coatings technology, the formulation with corrosion inhibitors is the most common approach. Despite the use of corrosion inhibitors has shown broad use and protection for several systems, their use in coated wires is limited due to the intrinsic characteristic of wires and their applications. Other, self-healing concepts in organic coatings use flow or reflow of the coating or the embedment of encapsulated liquid healing agents as the major mechanism to restore barrier protection at damaged sites.

Ionomers can be defined as polymers whose bulk properties are governed by ionic interactions within discrete regions of the polymer structure. The presence of ionic cluster and the combination of hydrogen bonding and interchain ionic forces provides high polymer strength but also a temperature triggered local mobility. Previous works showed that the combination of elastic flexibility, high melt strength and spontaneous formation of physical crosslinks give ionomers a self-healing behaviour upon ballistic impact [2], while it was also demonstrated that the ionomer modifiers do have an important effect in the healing capabilities under pseudo-static tests [3]. The presence of ionomer modifiers do have an important effect in the healing capabilities [4].

The research is focus on the implementation of temperature triggered healing organic coatings with intrinsic flow capabilities, using non-covalent reversible bond chemistries as encountered in ionomers. In the present work several modified ionomers have been applied as coatings on galvanized steel substrates and their healing and barrier properties evaluated by several techniques (e.g. electrochemical impedance spectroscopy, dielectric measurements, scratch testing-confocal and DSC testing). Results showed that modifiers do have an important effect in general properties such as adhesion and flow, leading to healing capabilities also under static healing, albeit at only modest degrees of local deformation.

References

- S.J. Garcia, H.R. Fischer, and S. van der Zwaag, Progress in Organic Coatings, 2011, 3, 211-221.

- S.J. Kalista, Mechanics of Advanced Materials and Structures, 2007, 5, 391-397.

- R.J. Varley and S. van der Zwaag, Acta Materialia, 2008, 19, 5737-5750.

- S.J. Garcia, R. Varley, and S. van der Zwaag, in 3rd International Conference in Self-Healing Materials, 2011, Bath, U.K.

Prof.dr. Lars Wågberg

Royal Institute of Technology, KTH, Stockholm, Sweden

Title lecture

Tailoring of adhesion using the Layer-by-Layer technology

Author

Lars Wågberg

Abstract

In many practical situations, such as gluing, papermaking, composite manufacture etc. it is vital to adhere one component to another. The problem is that the surfaces that are supposed to be joined are usually rough (on a molecular- and mesoscale) and they usually have a totally different surface energy and polarity which poses severe problems when trying to create a tailored interfacial adhesion. In many situations the problems are simply solved by trial and error but in advanced applications, such as for fibre reinforced composites, this approach is not enough and more sophisticated solutions are needed. Lately there has also been an increased interest in using strong nano-fibres, with high moduli and high aspect ratios, for the manufacture of light and strong composites. The problem for the preparation is two-fold from an adhesion point of view. First of all there has to be a good adhesion between the fibres and the polymeric matrix and then the fibres have to be homogeneously mixed within the matrix. Since many polymeric matrices have a low surface energy and a low polarity it is usually necessary to decrease the surface energy of the nano-fibres to ensure a good mixing. However, by doing so the thermodynamic work of adhesion between the two materials is decreased and further improvements are therefore needed to fully utilize the inherent properties of both the fibres and the polymeric matrix. In practice different crosslinking chemicals are added together with the fibres and many other routes including covalent attachment of oligomers and polymers to the fibres have been evaluated but there is still a lack of convenient methods for the tailoring of adhesive interactions between fibres and polymers. It is also vital that these methods should avoid the use of organic solvents.

An interesting approach for tailoring of surfaces and interfaces was developed by Decher and co-workers in the late 1980's1,2 and this consisted of a consecutive treatment of the surfaces with oppositely charged polyelectrolytes. With this LbL methodology it is possible to tune the polarity of the surfaces, to create molecular 3D-structures, to modify the wet and dry moduli of the surfaces and by selecting the correct polymer pairs it is also possible to build in a molecular mobility of the polymers that will increase the interfacial adhesion between solids that have been LbL modified.

The LbL methodology has also been used to improve the adhesion between wood-based fibres and fibrils. In these applications the fibres/fibrils have been consecutively treated with cationic and anionic polyelectrolytes before forming papers from the treated fibres. We have found that it is possible to increase the stress and strain at break of the papers fivefold with very thin layers of the polyelectrolytes. By performing model experiments , using colloidal probe AFM, model surfaces and model experiments using single fibre crosses it has also been possible to establish a link between molecular interactions in the wet state and dry properties of fibre/fibre joints and mechanical properties of papers prepared from the treated fibres. The results show that a good molecular attachment of the polymers to the surfaces is necessary and that polymer mobility across the interface is vital for the formation of a strong inter-fibre joint. We have also found that the mechanical properties of the thin films created on the surface of the fibres and fibrils have a profound effect of the mechanical properties of the networks formed from the treated fibres/fibrils.

Rerference

- Decher, G., Hong, J.D. and Schmitt, J., Thin Solid Films 210/211 (1992) 831

- Decher, G., Science 277(1997) 1232

Prof. Limin Wu*

The Advanced Coatings Research Center of Ministry of Education of China and Department of Materials Science, Fudan University, Shanghai, PR China

Title lecture

Preparation and Properties of Self-cleaning Coatings based on Poly(fluoro)siloxane/TiO2 Nanocomposites

Authors

Limin Wu, Shuxue Zhou, Xiaofeng Ding

Abstract

Large-scale fabrication of supra-amphiphilic or superhydrophobic self-cleaning coatings were conducted at room temperature by combining TiO2 nanoparticles with special polymer binders. The structure and properties (including durability, wetting behavior, mechanical properties, photocatalytic properties) of the coating were investigated in detail. The micro/nano structure formed under UV-irradiation or by self-organization of TiO2 nanoparticles is responsible for the enhanced wetting behavior of these coatings.

Te-Hui Wu

Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Inteface Chemistry, Eindhoven, Netherlands

Title lecture

Conductive composite coatings; an alternative for corrosion inhibition on aluminium alloys

Authors

T. H. Wu , A. Foyet, A. Kodentsov, L. G. J. van der Ven, R. A. T. M. van Benthem, G. de With

Abstract

In an attempt to improve the anti-corrosive properties of epoxy coatings on aluminum alloys, a conductive composite coating was tailored. AC conductivity measurements were carried out on the samples with different CB concentrations, showing that infinite conductive paths are formed through the polymeric matrix for a composite with CB concentration 1 vol%. However, due to a resistive barrier at the interface, as shown by both AC characteristics and TEM images, good electrical contact between CB networks and the substrate underneath is established when CB concentrations reaches 1.25 vol%. The studies of the anti-corrosive properties of composite coatings were carried out on samples filled with 1.25 vol% CB (F) and a reference sample without CB (CL). After 120 days of immersion in 0.5 M NaCl solution, no corrosion reaction can be observed by conventional EIS on both. In a next step, pin holes with a uniform diameter 500 μm were manually created on a F sample and a CL sample, and the accelerated corrosion reaction was investigated by micro-EIS, respectively. After 200 hours immersion, it was found that the decrease of impedance for a F sample was examined to be slower than that of a CL one by approximately a factor of 10. More experiments were done on different sets of coatings and showed consistent results. In addition, the propagation rate of visual corroded area for F samples is 10 times slower than that in CL samples. To have a deeper insight of this phenomenon, the scanning electrochemical microscopy (SECM) was employed, showing that the corrosion mechanism for F samples was transformed as anticipated from anodic undermining to cathodic delamination due to the presence of conduction paths. Electrons generated at anodic sites have chances to spread into the coatings, further reducing the risk of coating delamination caused by ion transportation. Finally, salt spray tests were performed on coatings without CB (CL), with 0.75 vol% CB, and with 1.25 vol% CB (F), verifying the eminent anti-corrosive performance of this conductive composite coating.