Speakers COSI 2013

- Mina Abdolah Zadeh, Novel Aerospace Materials Group, Faculty of Aerospace Engineering, Delft University of Technology, Delft, The Netherlands, Intrinsic self-healing sol-gel coatings based on epoxy alkoxysilanes containing dynamic di-sulfide bonds

- Mélanie D’Almeida, Laboratoire des Multimatériaux et Interfaces, Villeurbanne Cedex, France, A new biomaterial for dental implants obtained by coating of chitosan via silanation: biological and mechanical performances

- Dr. Viktor Baukh Department of Applied Physics, Eindhoven University of Technology, Eindhoven, The Netherlands, Understanding water uptake in multilayer coatings: The roles of composition and temperature

- Dr. Worawan Bhanthumnavin, Organic Synthesis Research Unit, Department of Chemistry, Faculty of Science, Chulalongkorn University, Bangkok, Thailand, Graft copolymerization coating of methacryloyloxyethyl diphenyl phosphate flame retardant onto silk surface

- Dr. Silfredo Javier Bohórquez, Nuplex Resins BV, Bergen op Zoom, The Netherlands, Efficient strategy for nano-hard-sphere usage: Boosting the performance of waterborne coatin

- Camille Carcouët, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands, Nature inspired raspberry-like silica nanoparticles for superhydrophobic coatings

- Prof. Dr. Stuart G. Croll, North Dakota State University, Dept. of Coatings and Polymeric Materials, Fargo, North Dakota, USA, Coarse-grained molecular dynamics study of the degradation of crosslinked polymer networks

- Prof. Dr. Céline Croutxé-Barghorn, Laboratory of Macromolecular Photochemistry and Engineering, University of Haute-Alsace, ENSCMu, Mulhouse Cedex, France, Nanocomposite coatings by UV driven sol-gel process and photopolymerization

- Akshya Kumar Guin, Research and Development, Tata Steel Ltd, Jamshedpur, India, Development and performance evaluation of corrosion resistance self healing coating

- Dr. Tom Hauffman, Vrije Universiteit Brussel, Department of Electrochemical and Surface Engineering, Brussels, Belgium, Study of molecular glues for coating adsorption on aluminium oxides: self-assembling of organic “mono”-layers of phosphonic acids

- Prof. Dr. Wayne Hayes*, Department of Chemistry, University of Reading, Whiteknights, Reading, Berkshire,UK, Branched comb polyesters: Application in fast drying solvent-borne coating formulations

- Dr. Stefan Holberg, Danish Technological Institute, Aarhus, Denmark, Application of a repellent urea-siloxane hybrid coating in the oil industry

- Prof. Dr. Mats Johansson, KTH, Royal Institute of Technology, Stockholm, Sweden, Photopolymerization of Biobased Monomer Systems

- Alexandros Kakaroglou, Research Group Electrochemical and Surface Engineering (SURF), Department of Materials and Chemistry (MACH), Vrije Universiteit Brussel, Brussels, Belgium Study of the effect of C=C bonds in organic coatings deposited with atmospheric plasma

- Patrick Keil, BASF Coatings GmbH, Münster, Germany, Influence of water uptake characteristics on functional properties of protective coatings: A combined EIS and SKP study

- Alexander Kröger,Coating Materials & Polymers, Universität Paderborn, Germany, Layer by layer assembly of aqueous graphene dispersions

- Prof. Dr. José Miguel Martín-Martínez, Adhesion and Adhesives Laboratory, University of Alicante, Alicante, Spain, Coatings properties obtained with waterborne polyurethane dispersions prepared with polycarbonates of 1,6 hexane diol of different molecular weights

- Lina Martinsson, KTH Royal Institute of Technology, Stockholm, Sweden The effect of superhydrophobic wetting state on corrosion protection - the AKD example

- Dr. Niels Meis, Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands, Extreme wet adhesion of a novel epoxy-amine coating on aluminum alloy 2024-T3

- Ralf Müller, University of Cologne, Cologne , Germany, CVD of metal oxide nanowires: Growth, applications and devices

- Kristian Petersen Nørgaard, Department of Chemical and Biochemical Engineering, Technical University of Denmark, DTU, Lyngby, Denmark, Performance of epoxy primers in intumescent coating systems

- Prof.Dr. Kevin Ogle*, Ecole Nationale Supérieure Chimie Paris, ParisTech Physical Chemistry of Surfaces, Paris, France, New insights into conversion coating stabilty and polymer delamination mechanisms

- José Alberto Olivares*, Centro de Investigación en Polímeros, COMEX, Lomas de Chapultepec, México DF, Drying dynamics of latex polymers by interferometric technique

- Önder Pekcan, Kadir Has University, Istanbul, Turkey, Fluorescence study of film formation from PS/Al2O3 nanocomposites

- Dr. Claudia Philipp, Fraunhofer-Institute for Wood Research, Wilhelm-Klauditz-Institut, WKI, Braunschweig, Germany, Unsaturated polyesters in aqueous miniemulsion

- Dr. Patrice Roose*,Allnex, Drogenbos, Belgium, UV-nanospheres: photopolymerized polymer colloids from aqueous dispersions of acrylated oligomers

- Dr. Michiel van Soestbergen, Material innovation institute, Delft, the Netherlands / Eindhoven University of Technology, The Netherlands, Release of low-soluble cerium corrosion inhibitors from organic coatings

- Ronald Tennebroek, DSM Coating Resins, Waalwijk, the Netherlands, Towards a better understanding of polyurethane particles using self-consistent field computations

- Dr. Ulrich Tromsdorf, BASF SE, Ludwigshafen, Germany, Zero-VOC binders for industrial metal coatings

- Dr. Matthias Wanner, Fraunhofer IPA, Stuttgart, Germany, Effects of the elution of waterbased corrosion protection primers on their protective properties

- Dr. ir. Mariëlle Wouters, TNO, Eindhoven, The Netherlands, Biobased binders for coating application

- Günter Wuzella, Kompetenzzentrum Holz GmbH, St. Veit a. d. Glan, Austria, Influence of thermoanalytical and rheological properties of an epoxy powder coating resin on quality of coatings using in-mold technology

- Weiyi Xing, State Key Laboratory of Fire Science, University of Science and Technology of China, Hefei, P.R.Chinam, Synthesis, thermal behavior and combustion of the novel UV-cured flame retardant coatings

- * At the COSI conference are two kinds of speakers: invited speakers and regular speakers. Invited speakers have been put forward by one or more of the committee members and are exempted from the paper selection procedure. Invited speakers are still obliged like the committee members to pay the full fee. Regular speakers have submitted a paper to be considered for presentation by the committee members. Regular speakers will be informed of their selection in February 2013. They also are obliged to pay the full fee. COSI only supports reduced fees for students if they either present a poster or give a lecture. Note: There is only a total of 34 lecture spaces of wich ~10 are reseverd for invited speakers.

Mina Abdolah Zadeh

Novel Aerospace Materials Group, Faculty of Aerospace Engineering, Delft University of Technology, Delft, The Netherlands

Title lecture

Intrinsic self-healing sol-gel coatings based on epoxy alkoxysilanes containing dynamic di-sulfide bonds

Authors

M. Abdolah Zadeh, A.C.C Esteves, S. van der Zwaag, S.J. Garcia

Abstract

Sol-gel coatings are commonly used as surface pre-treatments or as thin coatings to improve the adhesion and barrier protection provided by the coating system [1]. To improve the reliability of the system even further, such sol-gel coatings should have some self-healing ability. Extrinsic self-healing coatings, i.e. coatings in which the self-healing capability is due to the inclusion of nano- and micro-sized capsules filled with a corrosion inhibitor [2] can offer some corrosion protection. Yet cracks in extrinsic self-healing sol-gel coating will not disappear as the matrix is permanently cross-linked and hence immobile.

In this work we present a family of intrinsic self-healing sol-gel coatings capable of mending both superficial and interfacial damage. The new sol-gels coatings are based on hybrid epoxy-alkoxysilanes containing dynamic di-sulfide bonds for healing promotion. Upon application of moderate pressures and temperatures, the new systems flow and repair (i.e. close and seal) macroscopic scratches up to an approximate width of 500 µm [3].

The new sol-gel systems are thermally and mechanically characterized and their healing kinetics are evaluated as a function of composition and healing temperature. In order to get a better insight of the healing mechanism, thermo-mechanical tests are complemented by in-situ Raman spectroscopy to follow the status of the di-sulfide dynamic bonds during the healing process. In addition, micro-indentation techniques are employed to evaluate the effect of healing cycles on the overall mechanical properties. The electrochemical properties of the scratched and healed coatings are determined by electrochemical impedance spectroscopy (EIS) to monitor the ability of the coatings to restore their barrier functionality.

The current systems showed promising results and may provide the basis for the first generation of intrinsic healing sol-gel based coatings.

References:

- D. Wang, G.P. Bierwagen, Sol-gel coatings on metals for corrosion protection, Progress in Organic Coatings, 64 (2009) 327-338.

- S.J. Garcia, H.R. Fischer, S. van der Zwaag, A critical appraisal of the potential of self-healing polymeric coatings, Progress in Organic Coatings, 72 (2011) 211-221.

- M. Abdolah Zadeh, S.J. Garcia, S. van der Zwaag, Sol-Gel Based Intrinsic Self-Healing Polymers, in: 8th Coatings Science International, Noordwijk, The Netherlands, 2012, pp. 52.

Mélanie D’Almeida

Laboratoire des Multimatériaux et Interfaces, Villeurbanne Cedex, France

Title lecture

A new biomaterial for dental implants obtained by coating of chitosan via silanation: biological and mechanical performances

Authors

M. D’Almeida, P. Renoud, S. Benayoun, N. Attik, B. Grosgogeat, B. Toury

Abstract

During the last decade, the access to dental care has increasingly become a service requested by the population, especially in the case of dental implants. However, one of the causes of implant failure is inflammatory disease: Peri-implantitis. Currently, there are no implants which prevent these bacterial infections. In order to improve the antibacterial properties of a dental implant, a functionalization of titanium by coating of antibacterial biopolymer, chitosan, has been investigated. The attachment of chitosan to the metal substrate was performed via a silanation.

Firstly, surface chemistry and mechanical properties of the chitosan-coating were evaluated. The presence of the biopolymer on titanium was confirmed with FTIR analyses. Furthermore, the results showed that the coating has high scratch resistance and strong adhesion to the substrate. The inhibition of the growth of Actinomyces naeslundii, gingival bacteria was also demonstrated. However, it did not significantly inhibit another gingival bacteria Porphyromonas gingivalis after 32 hours in liquid media. A good biocompatibility of the coating to NIH3T3 fibroblasts was showed by SEM observations. The association of good mechanical properties along with the biocompatibility of the coating allows us to consider the use of these materials in implantology applications.

Dr. Viktor Baukh

Department of Applied Physics, Eindhoven University of Technology, Eindhoven, The Netherlands

Title lecture

Understanding water uptake in multilayer coatings: The roles of composition and temperature

Authors

V.Baukh, H.P. Huinink, O.C.G. Adan, L.G.J. van der Ven

Abstract

Exposure to water at different temperatures is a key process in the performance of coatings during their service life. This justifies studies of influence of water on coatings. Coatings are frequently applied in multiple layers, in order to meet the required specifications. Understanding the relation between the composition of the coating, temperature and water uptake is a challenge.

This paper presents an investigation of roles of temperature and composition on on water transport in base coat/top coat systems. The top coat is a highly crosslinked layer and base coats are waterborne physically dried layers with multiple polymer phases. The polymer dynamics in the top coat determines water penetration and exposure to water does not make structural changes in the top coat. Further, the connection between base coat formulation to water transport kinetics was determined. It was found that temperature significantly decreases the timescale of uptake. On the basis of the base coat composition the base coat sorption isotherm, which determines water uptake kinetics was reconstructed.

Dr. Worawan Bhanthumnavin

Organic Synthesis Research Unit, Department of Chemistry, Faculty of Science, Chulalongkorn University, Bangkok, Thailand

Title lecture

Graft copolymerization coating of methacryloyloxyethyl diphenyl phosphate flame retardant onto silk surface

Authors

W. Bhanthumnavin, P. Jermsutjarit, B. Paosawatyanyong

Abstract

This paper reports an efficient surface modification methodology to increase fire resistance properties of silk fabric performed by radio frequency (RF) plasma-induced graft copolymerization of vinyl phosphate ester as nanometer coating. Methacryloyloxyethyl diphenyl phosphate (MEDP) monomer was prepared and graft-copolymerized onto the surface of silk fabric by argon RF plasma at ambient temperature. Under optimum RF power (30 W), amounts of MEDP and N,N methylenebisacrylamide cross linking agent were varied to obtain optimum graft copolymerization conditions. Untreated and treated silk were characterized by attenuated total reflectance infrared (ATR-IR) spectroscopy to investigate their functional group characteristics. This showed a strong covalent attachment between the surface of silk and flame retardant material as the carbonyl functionality of the MEDP was clearly observed in the spectra. Scanning electron microscopic (SEM) analysis also showed grafted material as nanometer residue on silk surface. Thermogravimetric analysis (TGA) revealed that the decomposition of phosphorus compound which occurs at lower temperature than the silk itself resulted in the formation of char which covers the surface of the fabrics. This protects the fabric surface from further burning, therefore, higher amounts of remaining materials were observed as char in all cases. Furthermore, limiting oxygen index (LOI) had increased from 25 in untreated to 29 in the MEDP grafted silk. Detailed analysis on structural and thermal properties as well as surface grafting efficiency are presented.

Dr. Silfredo Javier Bohórquez

Nuplex Resins BV, Bergen op Zoom, The Netherlands

Title lecture

Efficient strategy for nano-hard-sphere usage: Boosting the performance of waterborne coatings

Authors

S.J. Bohórquez, J.S. Nunes, M. Meeuwisse, D. Mestach, J.M. Asua

Abstract

This work describes a study on the efficient use of waterborne (WB) polymeric nano-hard-spheres to improve properties of WB coatings such as: early hardness, blocking and resistance to fat. The WB nano-hard-spheres were synthesized by a special emulsion polymerization process enabling the use of low surfactant concentration and high solid levels, and then blended with different commercial decorative WB binders. The colloidal stability of these bimodal systems was carefully analyzed through rheology and light-scattering analysis. Afterwards, different clear coatings were formulated, prepared, and applied onto different substrates to evaluate their properties. Results showed that the implementation of this WB technology enhanced the performance of the systems evaluated for decorative and industrial purposes.

Camille Carcouët

Eindhoven University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands

Title lecture

Nature Inspired raspberry-like silica nanoparticles for superhydrobobic coatings

Authors

C.C.M.C. Carcouët, A.C.C. Esteves, R.A.T.M. van Benthem, G. de With

Abstract

Over the last decade, superhydrophobic surfaces have attracted much interest for both fundamental research and practical applications, mostly driven by the promise of self-cleaning properties of these coatings [1]. Mother Nature has delivered some of its secrets and research has revealed that the self-cleaning property of the Lotus leaf originates from a peculiar topology based on micro- and nanoscopic surface roughness combined with the hydrophobic properties of its epicuticular wax [2]. For synthetic coatings, a dual-size roughness combined with low surface energy species appears to be essential to reach superhydrophobicity. Considerable efforts have been focused on the development of such surfaces, through the design of the proper roughness. The use of raspberry-like silica particles has already been proven successful in making superhydrophobic coatings [3], but it also enables for a more systematic approach to investigate the effect of size and size ratio of the raspberry-like particles on the wetting properties of the coatings.

Prof. Dr. Stuart G. Croll

North Dakota State University, Dept. of Coatings and Polymeric Materials, Fargo, North Dakota, USA

Title lecture

Coarse-grained molecular dynamics study of the degradation of crosslinked polymer networks

Authors

S.G. Croll, D.M. Kroll, M. Zee

Abstract

Failure of a barrier coating occurs as the crosslinked polymer binder allows the passage of ionic or other species. These penetrants can cause corrosion of a metallic substrate or other damage. Molecular dynamics provides a means to examine the distribution of network crosslinks and properties at a level that is not currently possible with experimental techniques. Coarse-grained molecular dynamics were used to study polymer network formation by various reactive species that emulated those used in coatings. Degradation was effected by successively removing a small fraction of the bonds from the simulated networks and examining the consequences for the strength, continuity and permeability of the network. Network integrity, pore space distribution and its evolution during degradation depend on the functionality of the initial reactive species, the glass transition of the polymer network and the constraints present. Results here show how crosslinked polymer networks might permit the passage of corrosive species both as freshly crosslinked systems and after suffering environmental degradation.

Prof. Dr. Céline Croutxé-Barghorn

Laboratory of Macromolecular Photochemistry and Engineering, University of Haute-Alsace, ENSCMu, Mulhouse Cedex, France

Title lecture

Nanocomposite coatings by UV driven sol-gel process and photopolymerization

Authors

C. Croutxé-Barghorn, A. Chemtob, L. Ni, H. De-Paz-Simon, C. Belon

Abstract

Photosol-gel process combined with photopolymerization is a novel and simple route to produce organic-inorganic hybrid materials in a one step process avoiding further post-treatment. Upon UV irradiation, acids or bases are liberated through photoacid (PAG) or photobase (PBG) generator photolysis, allowing the generation of a polysiloxane network. Simultaneously, the organic polymerization is initiated by a cationic or radical process in combination. The peculiarity of the photoinduced pathway is the opportunity to control the reaction kinetics. In addition, the absence of solvent, the photolatency of the formulations and the one-step process are major advantages for industrial applications. This process is not only particularly adapted to the mechanical reinforcement of UV-cured coatings but also opens up the doors to the synthesis macroporous and mesoporous (organo)silica films.

Akshya Kumar Guin

Research and Development, Tata Steel Ltd, Jamshedpur, India

Title lecture

Development and performance evaluation of corrosion resistance self healing coating

Authors

Akshya Kumar Guin, Suryakanta nayak, Manish Kr. Bhadu, Veena Singh, Tapan Kumar Rout

Abstract

Polymer based nanocapsule was developed using core-cell approach where a core material was methyl diphenyl diisocyanide and cell was urea-formaldehyde.The capsules size and efficiency were optimized by ultrasonification technique. Synthesised capsule were characterized by different technique like FTIR and DSC, SEM-EDX. The synthesized capsules of 200 nm size were incorporated into titania sol-gel matrix to prepare a final coating for mild steel protection. This coating was found protecting the steel at the damage or crack locations in 3.5% NaCl solution. SEM images confirmed healing of the coating at the damage or crack point with in eight hour of damage and coating also enhance the corrosion resistance of steel substrate.

Dr. Tom Hauffman

Vrije Universiteit Brussel, Department of Electrochemical and Surface Engineering, Brussels, Belgium

Title lecture

Study of molecular glues for coating adsorption on aluminium oxides: self-assembling of organic “mono”-layers of phosphonic acids

Authors

T. Hauffman, T. Breugelmans;, Y. Van Ingelgem, E. Tourwé, V. Iancu, C. Van Haesendonck, A. Hubin, H. Terryn

Abstract

Self-assembling monolayers on oxide materials are of high interest due to their applications in various specialized fields. However, the occurrence of such SAMs has never been adequately proven. In this work we present the adsorption of phosphonic acids on aluminium oxides. Although these molecules are claimed to form a SAM on the oxide of aluminium, it could be proben by a set of complementary surface sensitive (vacuum) techniques and electrochemical methods that they do not. The main reason is the use of a solvent to assemble the molecules. Polar repulsion in water and corrosive environments in ethanol lead to different structures than those expected. The mechanisms of adsorption are discussed. Alternatives for the adsorption of the phosphonic acids, e.g. by physical vapour deposition, are shown.

Prof. Dr. Wayne Hayes

Department of Chemistry, University of Reading, Whiteknights, Reading, Berkshire, UK

Title lecture

Branched comb polyesters: Application in fast drying solvent-borne coating formulations

Authors

W. Hayes, G. Cheng, C. Lampard, N. Williams, M.S. Bahra and B.W. Greenland

Abstract

Novel oxazoline-based branched comb-polymers possessing linoleyl or oleic side chains have been synthesised and used to produce low viscosity coatings. Inclusion of the polymers in model paint formulations results in coatings that exhibit faster drying times than commercially available alkyd resin formulations. The polymers were produced from diol substituted oxazoline monomers that were synthesised through a scalable, solvent free protocol and purified by simple recrystallisation. Co-polymerisation of the oxazolines with adipic acid at 160 °C in the bulk resulted in the targeted polyester comb type polymers. The polymers were soluble in a range of organic solvents and compatible with commercial alkyd resins. Model paint formulations containing up to 40 wt% of the linoleyl-based comb polymers exhibited a dramatic reduction in viscosity (from 35 to 13 Poise at 25 °C) with increasing quantities of polymer added. Dynamic mechanical analysis (DMA) studies revealed that the drying rate of the model paint formulations containing the comb polymers was enhanced when compared with that of commercial alkyd resins.

Dr. Stefan Holberg

Danish Technological Institute, Aarhus, Denmark

Title lecture

Application of a repellent urea-siloxane hybrid coating in the oil industry

Authors

S. Holberg, C. Bischoff

Abstract

Urea-siloxane hybrid coatings have been prepared by the sol-gel method from a dipodal ureasilane and methyltriethoxsysilane. The coatings are suitable as corrosion protection and enable the incorporation of polydimethylsiloxane (PDMS) to achieve repellent properties. The effect of the PDMS chain length on the durability of the repellent properties has been investigated.

The coating has been applied on plate heat exchangers mounted on North Sea oil platforms to prevent crude-oil-derived fouling. While the uncoated heat exchangers get clogged by waxy substances and require costly maintenance in regular intervals, the coated heat exchanger significantly prolongs the service interval, at present by at least a factor of 3.

Professor Mats Johansson

Department of Fibre and Polymer Technology / Wallenberg Wood Science Center, KTH, Royal Institute of Technology, Stockholm, Sweden

Title lecture

Photopolymerization of Biobased Monomer System

Authors

M. Johansson

Abstract

The interest in a feed stock from renewable resources continuously increases in order to obtain a sustainable materials production in society. A wide variety of monomers are available from natural sources such as the forest and annual crops and significant efforts are made to further exploit these sources [1]. Numerous routes ranging from cationic polymerization of epoxidized vegetable oils [2] to free radical polymerization of acrylated oils have been used to exploit these monomers in coating systems. One system that more recently has obtained interest in this respect is thiol-ene systems where the ene-monomer has been derived from natural sources [3,4]. Internal main-chain (1,2 di-substituted) alkene groups are abundant in nature and finding an efficient way of polymerizing these alkene groups would allow a large number of new monomers to be used. It has been shown that the low reactivity of this type of double bonds in normal free radical polymerization can be significantly improved when combining these monomers with thiols. The relatively low reactivity can rather be an advantage since the monomers can be incorporated into larger resin systems without premature curing i.e. the resin synthesis becomes easier. The thiol-ene reaction has also been demonstrated to be a versatile reaction in the synthesis of biobased monomers as demonstrated by Meier [5] in the synthesis of diols for polyurethanes based on a terpene. The versatility of the thiol-ene reaction for radiation curable system based on biobased monomers will be demonstrated on a number of monomers ranging from vegetable oils to ene-functional polyester resins. Resin synthesis and cationic polymerization of epoxy monomers derived from Birch bark will furthermore be described.

References

- Monomers, polymers and composites from renewable resources." Eds. M. N. Belgacem and A. Gandini, Elsevier, 2008

- Crivello, J.; Narayan, R. Chemistry of Materials, 4, 692-699 (1992)

- Claudino, M.; Jonsson, M.; Johansson, M. European Polymer Journal 46, 2321-2332 (2010)

- Claudino, M.; van der Meulen, I.; Trey, S.; Jonsson, M.; Heise, A.; Johansson, M. Journal of Polymer Science, Part A: Chem Ed. 50, 16-24 (2012)

- Firdaus, M.; de Espinosa, L.M.; Meier M. A. R. Macromolecules, 44, 7253-7262 (2011)

Alexandros Kakaroglou

Research Group Electrochemical and Surface Engineering (SURF), Department of Materials and Chemistry (MACH), Vrije Universiteit Brussel, Brussels, Belgium

Title lecture

Study of the effect of C=C bonds in organic coatings deposited with atmospheric plasma

Authors

A. Kakaroglou, B. Nisol, G. Scheltjens, I. De Graeve, G. Van Assche, B. Van Mele, F. Reniers, H. Terryn

Abstract

The effect of unsaturations of atmospheric plasma deposition precursors have been studied in this work. Three precursors with similar structure but different amount of unsaturations (allyl methacrylate, n-propyl methacrylate and propyl isobutyrate) have been chosen to be deposited using dielectric barrier discharge atmospheric plasma. The deposited coatings have been characterised by various surface analysis techniques and the influence of the deposition parameters have been studied. A strong effect of the unsaturations of the monomer on the growth rate and the chemistry of the deposited coating has been observed. When two C=C bonds are present, high deposition rates can be achieved and the ester functionality is well retained. The barrier properties of the coatings have been also studied in order to evaluate the performance of the coatings when a topcoat is absent. It is shown that optimisation of the deposition parameters can considerably increase the barrier properties.

Patrick Keil

BASF Coatings GmbH, Münster, Germany

Title lecture

Influence of water uptake characteristics on functional properties of protective coatings: A combined EIS and SKP study

Authors

P. Keil, H. Hintze-Brüning, M. Groenewolt

Abstract

Electrochemical Impedance Spectroscopy (EIS) and Scanning Kelvin probe (SKP) amongst other analysis techniques were applied for principal investigations of the stability of the polymer/metal interface against delamination of technical coatings for automotive refinish or coil coating applications. In particular the investigation of kinetics of interfacial ion transport processes along a polymer/metal interface and their dependence on the structure of the polymer network is investigated. Thus, the parameters of interest in this study are the cross-link density, the nature of the used corrosion inhibition pigments and pre-treatments of the metal. EIS and SKP measurements allowed the evaluation of the electrochemical conditions at the interface for an improved evaluation of the stability of paint/metallic substrate interfaces against interfacial ion transport.

Alexander Kröger

Coating Materials & Polymers, Universität Paderborn, Germany

Title lecture

Layer by layer assembly of aqueous graphene dispersions

Authors

A. Kröger, K. Kohlgrüber, W. Bremser

Abstract

Functional materials based on single layer graphene have become a major field of interest in scientific research. Graphene has shown to exhibit fascinating properties like high thermal conductivity, electrical conductivity and high modulus. It is possible to stabilize and to exfoliate graphene in aqueous environment using either hexamethoxymethyl melamine (HMMM) emulsions or HMMM nano particle dispersions (HND). Functionalized graphene dispersions are obtained either with positive or negative zeta potential (+45 mV, -40 mV, respectively). The surface charge can be adjusted by variation of pH value. X-Ray diffraction and AFM measurements revealed a high degree of exfoliation. Concentrations average out at 1 g/L. The opposite charges enable the particles to be deposited on charged surfaces. Electrophoretic deposition (EPD) and layer by layer assembly (LBL) techniques were investigated in order to create novel hybrid materials based on the two-dimensional graphene. Both techniques allow deposition of graphene from aqueous dispersions while maintaining direct control over film thickness. In addition, EPD and LBL help to overcome the disadvantage of low concentrations common to graphene dispersions. Further research will point towards accurate process control and exploration of fields of application. This paper will present recent results on layer by layer assembly of modified graphene. Possible applications include creation of novel hybrid materials and electronic devices.

Prof. Dr. José Miguel Martín-Martínez

Adhesion and Adhesives Laboratory, University of Alicante, Alicante, Spain

Title lecture

Coatings properties obtained with waterborne polyurethane dispersions prepared with polycarbonates of 1,6 hexane diol of different molecular weights

Authors

Vanesa García-Pacios, Manuel Colera, Victor Costa, José Miguel Martín-Martínez

Abstract

Several waterborne polyurethane dispersions obtained with polycarbonates of 1,6 hexanediol of different molecular weights (500-3000 Da) were used to prepare coatings on stainless steel. The structure and properties of the polyurethane coatings were influenced by the molecular weight of the polycarbonate diol. The hatch adhesion of the polyurethane coatings to stainless steel was very good and decreased slightly by increasing the molecular weight of the polycarbonate of 1,6 hexanediol. Both the Pencil and Persoz hardness values of the coatings increased by increasing the hard segments content in the polyurethane, i.e. by decreasing the molecular weight of the polycarbonate of 1,6 hexanediol, whereas the gloss and the yellowness index values of the coatings were lower for the coatings obtained with the polyol of molecular weight of 500 Da. Very good chemical resistance against ethanol for all polyurethane coating was obtained but it decreased in the coatings prepared with polycarbonate diols of higher molecular weights for long time of ethanol in contact with the coating surface. Finally, it was concluded that the segmented structure of the polyurethane determined several coating properties.

Lina Martinsson

KTH Royal Institute of Technology, Stockholm, Sweden

Title lecture

The effect of superhydrophobic wetting state on corrosion protection - the AKD example

Authors

Lina Martinsson, Louise Ovaskainen, Irene Rodriguez-Meizoso, Pontus Olin, Lars Wågberg, Charlotta Turner, Agne Swerin, and Per Claesson

Abstract

The corrosion protective properties of superhydrophobic AKD surfaces greatly depend on the wetting regime exhibited by the surface. Four superhydrophobic surface coatings with different wetting regimes, but the same surface chemistry, were fabricated from AKD wax using different application methods resulting in hierarchical structures. Contact angle measurements (static, advancing and receding) and low vacuum SEM were used to determine which wetting regime was prominent for each sample. The corrosion protective properties were evaluated using electrochemical impedance spectroscopy and open circuit potential. The two samples with "lotus-like" wetting regime showed remarkably high impedance values simultaneously as the open circuit potential measurement suggested that the circuit was broken. These results can be explained by the formation of a thin air film at the water-coating-interface, significantly reducing the transport of ions from the solution through the coating to the substrate, thus breaking the circuit. The remaining two samples were in the "rose-like" and "Wenzel" wetting regimes, respectively, and showed less promising corrosion protection, probably because of the surfaces' increased affinity for water not allowing the thin air barrier to form.

Dr. Niels Meis

Eindhoven, University of Technology, Department of Chemical Engineering and Chemistry, Laboratory of Materials and Interface Chemistry, Eindhoven, The Netherlands

Title lecture

Extreme wet adhesion of a novel epoxy-amine coating on aluminum alloy 2024-T3

Authors

N.N.A.H. Meis, L. G. J. van der Ven, R. A. T. M. van Benthem, G. de With

Abstract

Epoxy resins are widely used as matrix materials for structural composites employed in aerospace industry. This work focuses on the investigation of different epoxy-amine coatings on the adhesion performance on aluminum AA-2024 substrates. Different epoxies (Epikote 828 (aromatic) and Eponex 1510 (aliphatic)) and different amines (1,8-diaminooctane, Dytek A, Jeffamine EDR148 and Jeffamine D230) as curing agent were used in different stoichiometric ratios. The coatings were characterized using DSC, DMA, pull-off tests and water-uptake measurements. Pull-off tests in dry conditions showed comparable adhesion of the coatings. Surprisingly, pull-off results showed after water soaking a higher wet adhesion of the coatings prepared with Eponex 1510 as compared to coatings prepared with Epikote 828. Moreover, the combination of Eponex 1510-Jeffamine EDR148 coatings resulted in high adhesion values with pull-off tests and these values did not change after immersion for two weeks in water. Furthermore, in contrast with Epikote 828 water uptake measurements showed almost nil water uptake for all coatings prepared with Eponex 1510.

Kristian Petersen Nørgaard

Department of Chemical and Biochemical Engineering, Technical University of Denmark, DTU, Lyngby, Denmark

Title lecture

Performance of epoxy primers in intumescent coating systems

Authors

Kristian Petersen Nørgaard, Kim Dam-Johansen, Pere Català, Søren Kiil

Abstract

Protection of steel structures, using intumescent coatings, is an efficient and space saving way to prolong the time before a building, with load bearing steel constructions, collapses in the event of a fire. In addition to the intumescent coating, the steel may require application of a primer, to ensure adhesion of the intumescent coating or to provide corrosion resistance. Two epoxy primers, one which performed well and another which performed poorly, when tested under an acrylic intumescent coating exposed to a gas fired test furnace, following, a so-called cellulosic fire curve, were selected for this study. The evaluation was carried out using; Imaging with digital- and scanning electron microscope pictures, a specially designed test oven, and thermo gravimetric analysis. The main mechanism of importance to the primers appears to be the resistance of the intumescent coating towards oxygen penetration.

Ralf Müller

Inorganic and Materials Chemistry, University of Cologne, Cologne, Germany

Title lecture

CVD of metal oxide nanowires: Growth, applications and devices

Authors

Sanjay Mathur

Abstract

One dimensional (1D) inorganic materials are gaining increasing attention because of their unique structural features and interesting functional properties. Given the structural stability, they show promising application potential in vacuum as well as in oxidizing atmospheres, which provides them a competitive edge over their carbon-based counterparts. A number of synthetic procedures have been developed and demonstrated for

1D nanostructures that have led to intriguing morphological variations (wires, tubes, belts, rods, etc.), however the control over radial and axial dimensions remains a continuing challenge. In addition, the choice of material is rather limited. We have developed a generic approach for the size-selective and site-specific growth of nanowires by combining vapor-liquid-solid (VLS) approach with the chemical influence of molecular precursors.

The synthesis of nanowires (NWs) is based on the decomposition of discrete molecular species in the liquefied Au-Si alloy, which allows growing nanowires at low-temperatures with a precise control over their diameter and length. The precursor chemistry can be tuned to facilitate the stripping of organic ligands and to achieve complete decomposition that is critical for maintaining the gas phase super-saturation necessary for 1D growth. High-yield synthesis of NWs of tin, vanadium and iron oxides was performed by the chemical vapor deposition of appropriate metal-organic precursors. Axial and radial dimensions of the NWs were varied in the ranges 50-1500 nm and 25-40 µm, respectively by adjusting the precursor feedstock, deposition temperature, and catalyst size. We have investigated the device potential of these building blocks as photo- and gas sensors. For instance, illuminating tin oxide NWs with UV photons triggers interesting photo-conductance, which can be modulated by tuning the wire diameter as demonstrated for samples possessing radial dimensions in the range 50–1000 nms. The stable photo-response over several on-off cycles demonstrated their potential for applications in UV detectors or optical switches, where the NWs can act as resistive elements whose conductance changes by charge-transfer processes. In addition, tin oxide NWs were grown on sensor platforms and their response towards Co was compared with nanostructured tin oxide films.

This talk will address the generic feature of our approach for the synthesis of oxide nanowires of various compositions and present the results obtained on device applications

Prof. Dr. Kevin Ogle

Ecole Nationale Supérieure Chimie Paris, ParisTech Physical Chemistry of Surfaces, Paris, France

Title lecture

New insights into conversion coating stabilty and polymer delamination mechanisms

Authors

Kevin Ogle

Abstract

This presentation will explore the relationship between conversion coating stability and the mechanisms of electrochemically driven polymer delamination. Electrochemical experiments will be presented that permit a quantification of the relationship between electrochemical current and delamination rate for polymer coatings on zinc and galvanized steel. Atomic emission spectroelectrochemical experiments will be presented that allow us to quantitative the degradation of a metal / conversion coating system to either an aggressive electrolyte such as might be formed under paint or to a direct electrochemical perturbation.

José Alberto Olivares

Centro de Investigación en Polímeros, COMEX, Lomas de Chapultepec, México DF

Title lecture

Drying dynamics of latex polymers by interferometric technique

Authors

J.A. Olivares, J.M. Galván Miyoshi, R. Mascorro, F.L.S. Cuppo, J.P Acosta Ramirez, A. García Valenzuela and F. Zaldo

Abstract

Latex film formation is one of the key problems in the coatings industry since it is involved the film structure and the drying time. The requirement for low volatile organic content (VOC) in coatings demands latex with similar mechanical and structural properties similar to solvent based binders. In our particular case the drying time and film formation at surface plays a central role on the appearance of the coating and therefore studying the drying dynamics will help to shed some light on the film formation mechanism for the new generation of low VOC emulsions. In this work we present preliminary results on film formation for latex with different particle size and its corresponding mixtures by using an interferometric technique along with a refractive index gradient model to study how the latex layers are built. This technique allows us to monitor the film formation process in real time and the solvent (water) distribution inside the film.

Önder Pekcan

Kadir Has University, Istanbul, Turkey

Title lecture

Fluorescence study of film formation from PS/Al2O3 nanocomposites

Authors

Ö. Pekcan, Ş. Uğur and M.S. Sunay

Abstract

Steady state fluorescence (SSF) and UV-vis (UVV) techniques were used to study the film formation behavior polystyrene (PS) latex/ Al2O3 composites depending on PS particles size and Al2O3 content. The close-packed arrays of PS spheres (SmPS: 203nm ; LgPS: 382nm) template were covered with various layers of Al2O3 by dip-coating method. Two different film series, SmPS/Al2O3 and LgPS/Al2O3, were prepared in various Al2O3 layer content. The film formation behavior of these composites were studied by annealing them at a temperature range of 100 °C-250 °C and monitoring the scattered light (Isc), fluorescence (IP) and transmitted light (Itr) intensities after each annealing step. The results indicate that classical latex film formation was occurred for all Al2O3 content films and unaffected by the Al2O3 content for both film series. Extraction of PS template produced highly ordered porous structures for high Al2O3 content in both film series.

Dr. Claudia Schirp (Philipp)

Fraunhofer-Institute for Wood Research, Wilhelm-Klauditz-Institut, WKI, Braunschweig, Germany

Title lecture

Unsaturated polyesters in aqueous miniemulsion

Authors

C. Philipp

Abstract

Coating resins are driving to waterborne systems, which can be performed by primary or secondary dispersion of the polymer in water. In this context, primary dispersions of polycondensation reactions under aqueous conditions are not widely studied. As shown in this study, unsaturated polyesters can be synthesized in an aqueous miniemulsion using an acidic catalyst as surfactant. The use of a saturated comonomer enables the production of stable dispersions compared to polycondensations with solely unsaturated monomers as dicarboxylic acid component. Further improvement of the dispersion stability and the yield could be obtained by lowering the reaction temperature and by using alkyl esters with reduced polarity instead of dicarboxylic acids. The product of the reaction is a low-molecular weight polymer whose polymer latex remains stable throughout the reaction which allows further copolymerization thereafter. In-situ polymerization of graft-copolymer may offer a great opportunity by combining properties of polyester and polyacrylics.

Dr. Patrice Roose

Allnex, Drogenbos, Belgium

Title lecture

UV-nanospheres: Photopolymerized polymer colloids from aqueous dispersions of acrylated oligomers

Authors

P. Roose, M. Berlier, P. De Doncker

Abstract

Polymer colloids are usually prepared via a process where polymerization is thermally activated. However, photo-activated techniques for the preparation of polymerized or cross-linked colloids have seldom been reported in the literature and to our knowledge none has found real application in industry. Here, we introduce a new approach to form cross-linked colloidal particles in situ starting from aqueous dispersions of water-dispersible acrylated oligomers intended for use in water-based UV-coating applications. Of particular interest is the relatively high rate at which particle polymerization takes place even in highly opaque conditions e.g. with particle loadings of more than 20 w/w% and particle sizes ranging from 40 to 500 nm. Batch as well as continuous photoreactors can be used successfully. Furthermore, the composition of the oligomer particles, typically acrylated urethane backbones, can be tailored to control the final particle stiffness after photopolymerization. Hence, particles ranging from soft rubbery to hard rigid can be produced. In this paper, the preparation and the properties of this new family of organic colloids will be discussed along with some promising applications such as additive encapsulation.

Dr. Michiel van Soestbergen

Material innovation institute, Delft, The Netherlands / Eindhoven University of Technology, Eindhoven, The Netherlands

Title lecture

Release of low-soluble cerium corrosion inhibitors from organic coatings

Authors

M. van Soestbergen, V. Baukh, S.J.F. Erich, H.P. Huinink, and O.C.G. Adan

Abstract

Organic coatings are used for the corrosion protection of e.g. airplanes, bridges, or cars. To increase their inherent protective properties corrosion inhibitors can be added. For over a century chromates have been used for this purpose since they possess excellent inhibition properties. However, chromate is found to be carcinogenic and is therefore almost completely banned as a corrosion inhibitor. The replacement of chromates as a corrosion inhibitor in organic coatings is very challenging. Namely; there is a vast amount of available materials that can inhibit corrosion in an aqueous environment. However, whether they are effective as an additive in a coating also depends on their interaction with the organic matrix [1], which should result in a sufficient release of inhibitors over a desired period of time to spots that are susceptible to corrode. This interaction results in a tedious selection procedure for the appropriate inhibitor-coating combination. A thorough understanding of the underlying physicochemical mechanisms can relief this procedure. In this contribution we study the release mechanism of cerium corrosion inhibitors.

Cerium corrosion inhibitors, e.g. Ce(NO3)3 or CeCl3, are excellent corrosion inhibitors in an aqueous environment. However, when incorporated in a coating matrix they are prone to leach in too large amounts, which is probably related to their high solubility in water. To decrease this solubility, organic anions are used in combination with cerium cations. We report on cerium dibutylphosphate, Ce(dbp)3, which is only scarcely soluble in water [2]. Indeed, it was found by Hughes et al. [3] that the leaching rate of Ce(dbp)3 from an organic coating was low, whereas Mardel et al. [4] found that only a small amount of the available Ce(dbp)3 leaches out of the coating.

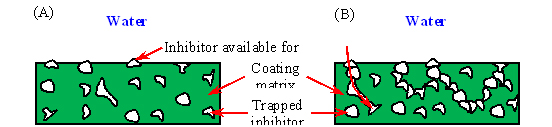

We studied the effect of the initial inhibitor loading of the coating on the leaching rate. In order to do this we determined the leaching rate of Ce(dbp)3 inhibitors from epoxy coatings containing loadings below and above the inhibitor percolation limit. It was found that the amount of leaching depends on the pH of the solvent and the initial loading; where at low pH and high loading the highest leaching rate was achieved. To explain this behavior we have used scanning electron microscopy to study the state of inhibitors in the polymer matrix, and nuclear magnetic resonance imaging to study the Ce(dbp)3/ water front during the leaching process. Additionally, the coating permeability, both for water and the inhibitors, has been determined. For the epoxy coating used in this work it was found that its permeability for the Ce(dbp)3 inhibitors is negligible and it is therefore likely that only the inhibitors which are directly exposed to water can leach from this coating (see Fig. 1).

Figure 1: Schematics of inhibitor release process; below (a) and above (b) the percolation limit of particles.

References:

- E. Javierre, S.J. Garcia, J.M.C. Mol, F.J. Vermolen, C. vuik, S. van der Zwaag, Progress in Organic Coating 75 (2012) 20-27.

- M. van Soestbergen, S.J.F. Erich, H.P. Huinink, O.C.G. Adan, Corrosion Engineering, Science and Tecnology Accepted for publication.

- A.E. Hughes, I.S. Cole, T. Muster, R.J. Varley NPG Asia Materials2 (2010) 143.

- J. Mardel et al. Progress in Organic Coating 70 (2011) 91-101.

Ronald Tennebroek

DSM Coating Resins, Waalwijk, The Netherlands

Title lecture

Towards a better understanding of polyurethane particles using self-consistent field computations

Authors

Feng Li, Ilse van Casteren, Ronald Tennebroek, Remco Tuinier

Abstract

The physical properties of waterborne dispersions such as dispersion stability and film formation process depend on the chemical composition of the polymeric building blocks. It is important to gain insight into the particle structures formed as a function of the building block chemistry. We have performed self-consistent field (SCF) computations to investigate how the stability of polyurethane (PU) dispersions depends on the chemical composition of (partly charged) mixtures of hard and soft block sequences mimicking polyurethanes. In this simulation work, we studied the influence of chemical compositions and building block sequences on the PU dispersions. The SCF model is able to predict the chemical composition distribution of the isocyanate functional prepolymer within the PU particles. Finally, we studied the correlations between PU micelle size and solid content of the prepolymer. We discuss the relationship between experimental work and our theoretical predictions.

Dr. Ulrich Tromsdorf

BASF SE, Ludwigshafen, Germany

Title lecture

Zero-VOC binders for industrial metal coatings

Authors

U. Tromsdorf, M. Dargatz, S. Grandhee

Abstract

The replacement of solvent-borne coatings is one of the major challenges of the lacquer industry. In particular in the field of corrosion protection in heavy-duty environments solvent-borne technologies are still dominating. Due to a more stringent legislation and environmental concerns there is a huge market potential for water-borne high performance technologies.The performance profile of an industrial coating places high requirements on key properties like barrier, resistance to water and chemicals, mechanical robustness and optical appearence. The polymeric binder significantly influences these properties. In this context, the mechanism of film formation, the achievement of sufficient crosslinking densities and adhesion to the substrate play a crucial role.

By using optimized polyacrylate emulsion polymers it is shown that homogeneous film formation can be achieved without coalescents.The properties can be tuned by tailoring the morphology of the latex particles and can be further improved by introduction of various functional monomers to the system. The films obtained from these emulsion polymers provide superior barrier properties.If suitably formulated into anticorrosive primers, the polymeric binders lead to very high salt-spray durabilities.The interaction with various formulation ingredients such as active pigments will be also addressed.

Dr. Matthias Wanner

Fraunhofer IPA, Stuttgart, Germany

Title lecture

Effects of the elution of waterbased corrosion protection primers on their protective properties

Authors

M. Wanner, K. Krawczyk, T. Schauer, T. Stingl, M. Melchiors

Abstract

Due to European REACH regulation waterbased corrosion protection coatings are in the focus of interest. The literature, however, often reports unfavourable short-time test results for such systems, even if they show sound performance in outdoor weathering. This discrepancy relates to the extended duration of the film formation and the retention of hydrophilic components in the polymer film. Using a procedure, which induces an accelerated film formation and elution of soluble hydrophilic components (e.g. monomers, oligomers, emulsifiers etc.) from the matrix the potentially impacting elution occurring under outdoor conditions may be simulated. Samples of five corrosion protection primers were characterized regarding their protective properties with and without performing such a preliminary elution procedure. These characterizations concerned the barrier properties and the water balance and showed that for some of such pre-conditioned waterbased coatings improved protective properties were found.This finding suggests that failingt of the elution procedure may be the reason for unfavourable short-time test results, which do not correspond with the outdoor weathering performance of waterbaed corrosion protection coatings.

Dr. ir. Mariëlle Wouters

TNO, Eindhoven, the Netherlands

Title lecture

Biobased binders for coating application

Authors

Mariëlle Wouters, Bastiaan Ingenhut, Pascal Welzen, Corné Rentrop, Klaas Timmer

Abstract

Within the development of novel materials for existing applications the concept of Green Chemistry and biobased economy is of great importance. One of the concepts of Green Chemistry is the prevention of waste and economical use of resources. Coatings fit very well in this concept with respect to production and application. Another part of the Green Chemistry concept is the use of renewable materials. For coatings and resins this part is an interesting field of research already for significant period of time. Within this presentation we will focus on the synthesis of novel binder materials for powder coatings that will be crosslinked with innovative chemistries that allow thermoplastic processing of the materials, including self healing. , Thus, introducing a potential recycling or repair of the coatings.

Günter Wuzella

Kompetenzzentrum Holz GmbH, St. Veit a. d. Glan, Austria

Title lecture

Influence of thermoanalytical and rheological properties of an epoxy powder coating resin on quality of coatings using in-mold technology

Authors

G. Wuzella, A.R. Mahendran, A. Kanderbauer, U.Müller, A. Teischinger

Abstract

An epoxy powder coating resin was applied on medium density fiberboards (MDF) and in-mold cured in a hot-press at different conditions. Some surface properties of in-mold coated MDF were determined. For thermal cure kinetics analysis of the resin differential scanning calorimetry (DSC) in combination with iso-conversional approach of Vyazovkin was used. The influence of in-mold cure temperature and tempering after cure on the development of glass-transition temperature (Tg) was also investigated by DSC. Measurements of resins viscosity in the course of temperature associated with cure kinetics and Tg were used to find the influence of these properties on the coating properties.

Weiyi Xing

State Key Laboratory of Fire Science, University of Science and Technology of China, Hefei, P.R.China

Title lecture

Synthesis, thermal behavior and combustion of the novel UV-cured flame retardant coatings

Authors

Weiyi Xing, Lei Song, Yuan Hu

Abstract

The novel organo-phosphorus acrylate BTP containing acid and carbon source, and BDEEP were synthesized successfully. The structures for these flame retardants were characterized by Fourier transformed infrared spectroscopy (FTIR), 1H nuclear magnetic resonance spectroscopy (1H NMR). The combustion behavior of flame retarded materials was evaluated by Limited Oxygen Index (LOI), Micro-scale Combustion Calorimeter (MCC) and Cone Calorimeter (Cone). It was found that the addition of BTP obviously increased the flame retardancy of PUA. The LOI of PUA could increase from 19.0 to 30.5, and the heat release rate decreased by 66.0%. Thermal degradation of flame retarded materials was studied by thermogravimetric analysis (TGA), and thermogravimetric analysis/infrared spectrometry (TGA-IR). It was found that the phosphate in BTP decomposed to form poly(phosphoric acid) at low temperature, which catalyzed PUA carbonization, and increased the thermal stability at high temperature. The volatilized products formed on thermal degradation of BDEEP were CO, CO2, water, alkane, carbonyl, phosphorus compounds and aromatic compounds according to the temperature of onset formation.